Oxygen blowing and coal injection secondary lead smelting furnace and oxygen blowing and coal injection method

A technology for smelting furnace and regenerating lead, which is applied to coal injection regenerating lead smelting furnace and the fields of oxygen blowing, oxygen blowing and coal injection, can solve the problem of low smelting efficiency, coal powder cannot be directly injected into the molten liquid, and coal powder combustion is insufficient. and other problems, to achieve the effect of reducing slag production, shortening smelting time, and wide range of coal powder particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

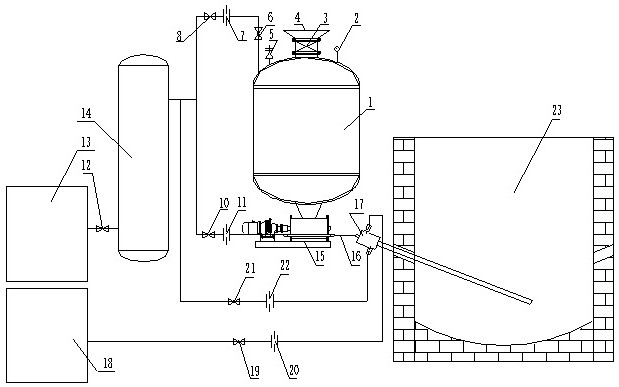

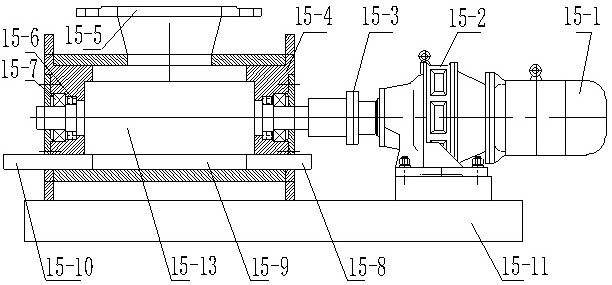

[0059] Embodiment 1: Oxygen blowing, coal injection regenerated lead smelting furnace includes: coal injection tank 1, pressure gauge 2, coal feeding valve 3, coal hopper 4, safety valve 5, air inlet valve 6, air inlet flowmeter 7, air inlet Pressure regulating valve 8, air injection pressure regulating valve 10, air injection flow meter 11, gas storage pressurization valve 12, air compressor 13, gas storage tank 14, coal injection machine 15, coal injection pipe 16, coal injection oxygen lance 17, oxygen Station 18, oxygen pressure regulating valve 19, oxygen flowmeter 20, compressed air pressure regulating valve 21, compressed air flowmeter 22 and melting furnace body 23;

[0060] The outlet at the bottom of the coal injection tank 1 is connected to the feed port 15-5 of the coal injection machine 15; the inlet end of the coal injection machine 15 is connected to the gas storage tank through the gas injection flow meter 11 and the gas injection pressure regulating valve 10 co...

Embodiment 2

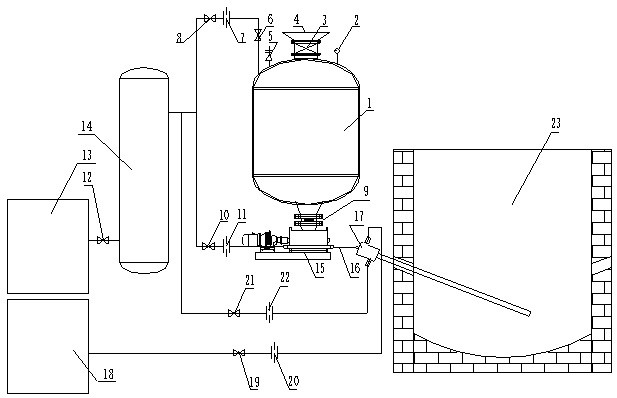

[0091] Example 2: In figure 2 Among them, the oxygen-blowing and coal-injection regenerative lead smelting furnace also includes: a coal discharge valve 9; a coal discharge valve 9 is connected to the discharge port at the bottom of the coal injection tank 1; a coal injection machine 15 is connected to the outlet end of the coal discharge valve 9 . Others are the same as in Example 1.

Embodiment 3

[0092] Example 3: In Figure 8 Among them, there are no less than two outlets at the bottom of the coal injection tank 1 . A coal injection machine 15 is connected to each discharge port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com