Processing technology of mixed amine

A processing technology and mixed amine technology, which is applied in the field of mixed amine processing technology, can solve the problems of high consumption of raw materials, large water pollution, and air pollution, and achieve the goals of avoiding environmental pollution, reducing cost consumption, and reducing raw material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

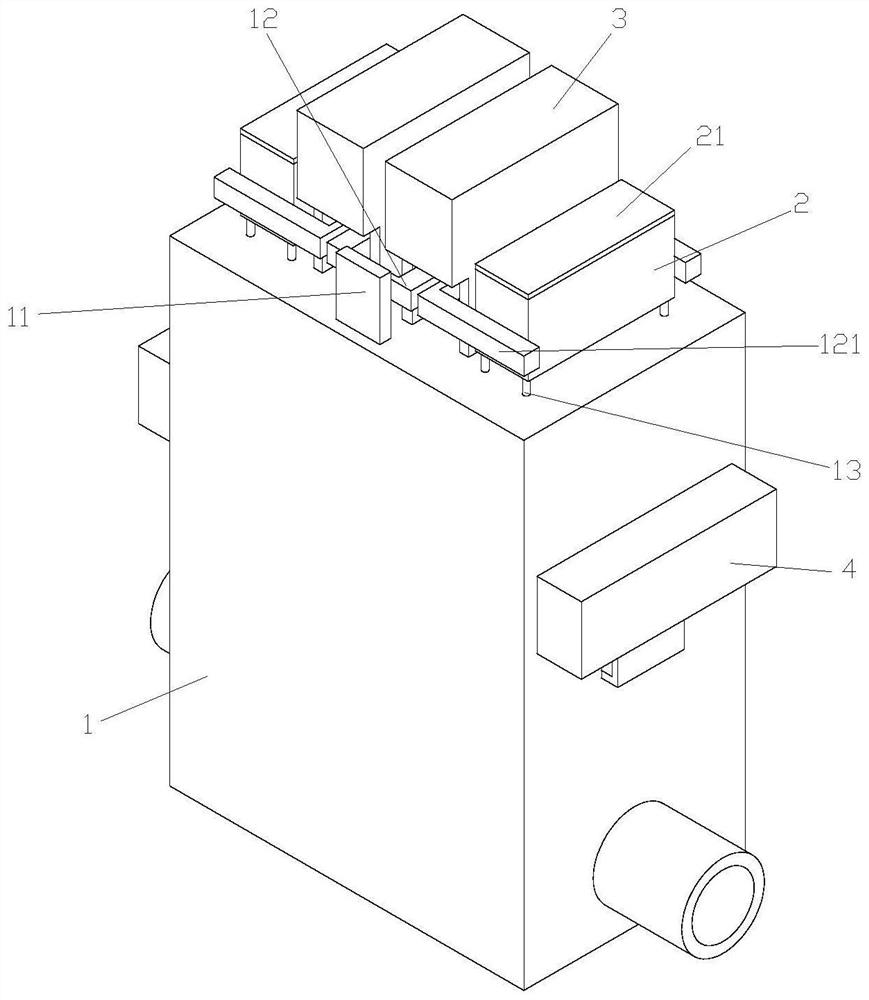

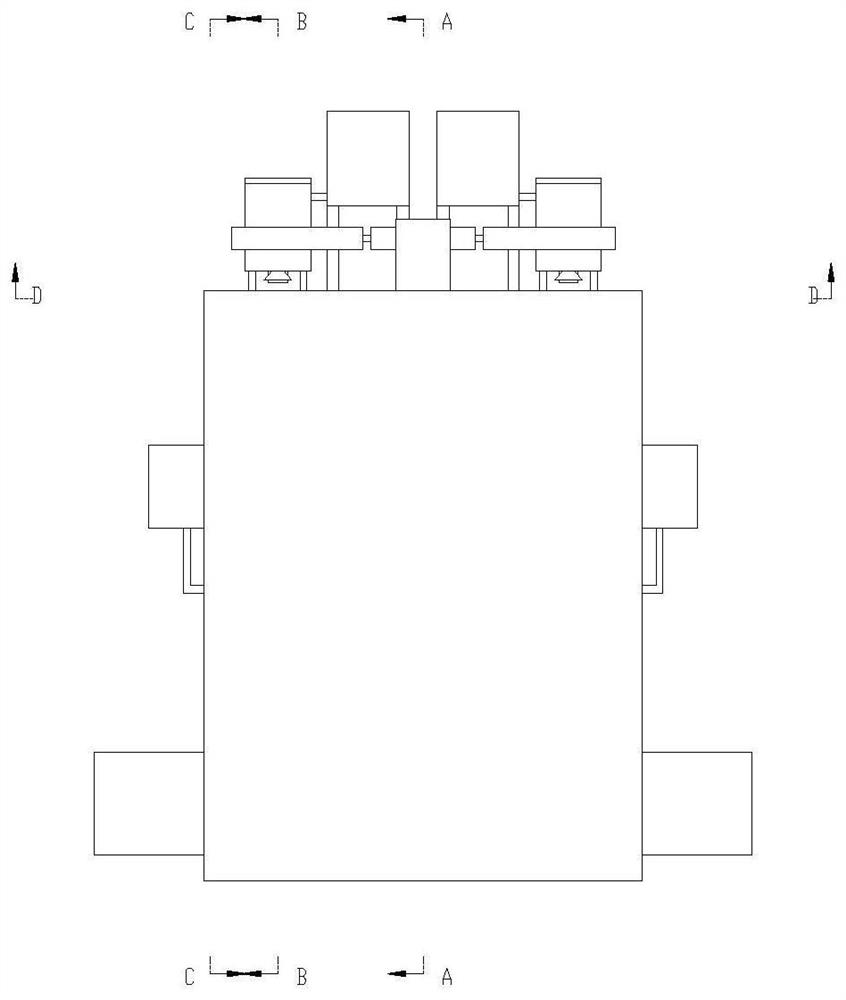

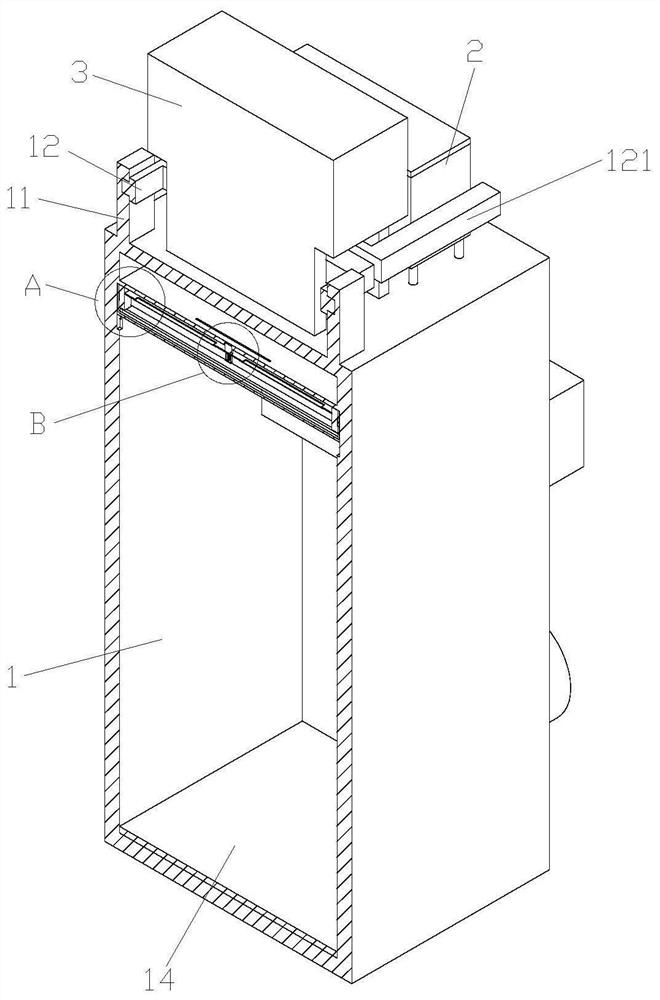

Image

Examples

Embodiment Construction

[0049] A processing technology of mixed amines, comprising the following steps:

[0050] a. Reduce the pressure of the mixture containing methylamine and methyldiethanolamine to 1-1.5MPa through the first pressure reducing valve, and pass it into the bottom of the deamination tower. The temperature of the bottom kettle of the deamination tower is controlled at 135-145°C. The methylamine in the vaporization rises to the top of the deamination tower and enters the condenser to be liquefied into liquid methylamine for recovery, and there is a mixture residual liquid containing N-methyldiethanolamine at the bottom of the tower;

[0051] B, the mixture residue containing N-methyldiethanolamine enters the flash tower through the second pressure reducing valve, and the mixture residue of N-methyldiethanolamine is distilled and separated into methylamine and N-methyldiethanolamine crude product;

[0052] C, the methylamine separated by N-methyldiethanolamine crude product in the flash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com