Preparation method of stable nanometer yttrium oxide powder

A nano-yttrium oxide and powder technology is applied in the field of preparation of rare earth ultrafine powder, can solve the problems of complicated operation, reduced powder activity, unfavorable transparent ceramic preparation and application, etc., and achieves high purity, low cost, and easy industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of stable nanometer yttrium oxide powder, comprises the following steps:

[0024] (1) Prepare an aqueous solution of yttrium salt with a concentration of 0.1-1mol / L, which is recorded as solution A;

[0025] (2) preparation contains the mixed precipitant solution of triethanolamine and ammonium bicarbonate, and is recorded as B solution;

[0026] (3) A solution and B solution are dripped into the other side by titration, and a precipitation reaction occurs. After the titration ends, the suspension of the precipitate containing yttrium is obtained, which is designated as C solution;

[0027] (4) Continue to stir the obtained C solution for a period of time, then age, separate by suction filtration to obtain the precipitate, then wash and dry the precipitate to obtain the yttrium oxide precursor;

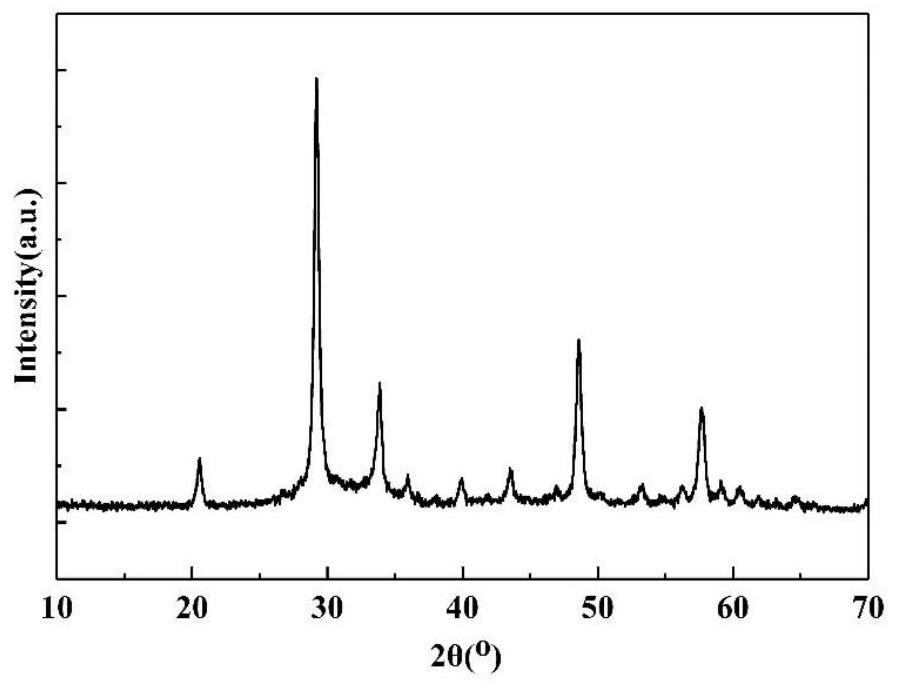

[0028] (5) Put the above precursor into a high-temperature resistance furnace for firing to obtain nanometer yttrium oxide ...

Embodiment 1

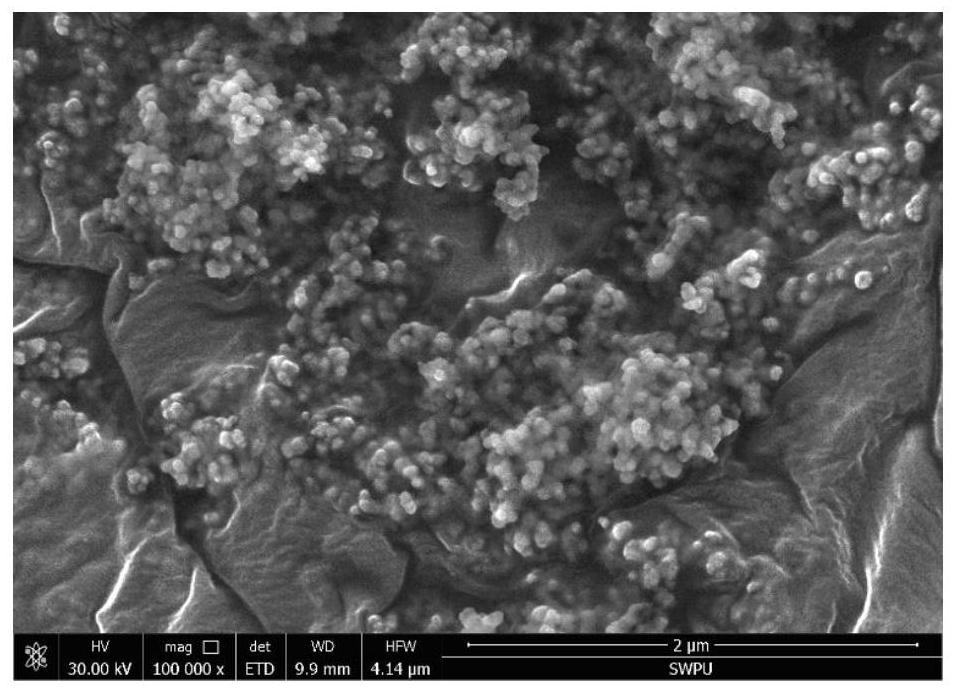

[0037] Prepare 500ml of yttrium nitrate aqueous solution of 0.2mol / L; Prepare the composite precipitant solution 500ml of triethanolamine and ammonium bicarbonate, wherein the concentration of ammonium bicarbonate is 0.2mol / L, the total number of moles of triethanolamine and ammonium bicarbonate and nitric acid The molar ratio of yttrium is 4:1; Add the composite precipitant solution dropwise in the yttrium nitrate aqueous solution at a speed of 10ml / min, stir while adding dropwise, the stirring speed is 65rpm, after the composite precipitant solution is added dropwise After continuing to stir at a speed of 65rpm for 30min, stop stirring, leave the resulting mixture at room temperature for 6h, then filter the mixture with suction to obtain a precipitate of yttrium; wash the precipitate of yttrium with deionized water 3 times, Then washed twice with absolute ethanol, dried in a drying oven at 90 °C for 6 h after washing to obtain the yttrium oxide precursor; finally, the precurs...

Embodiment 2

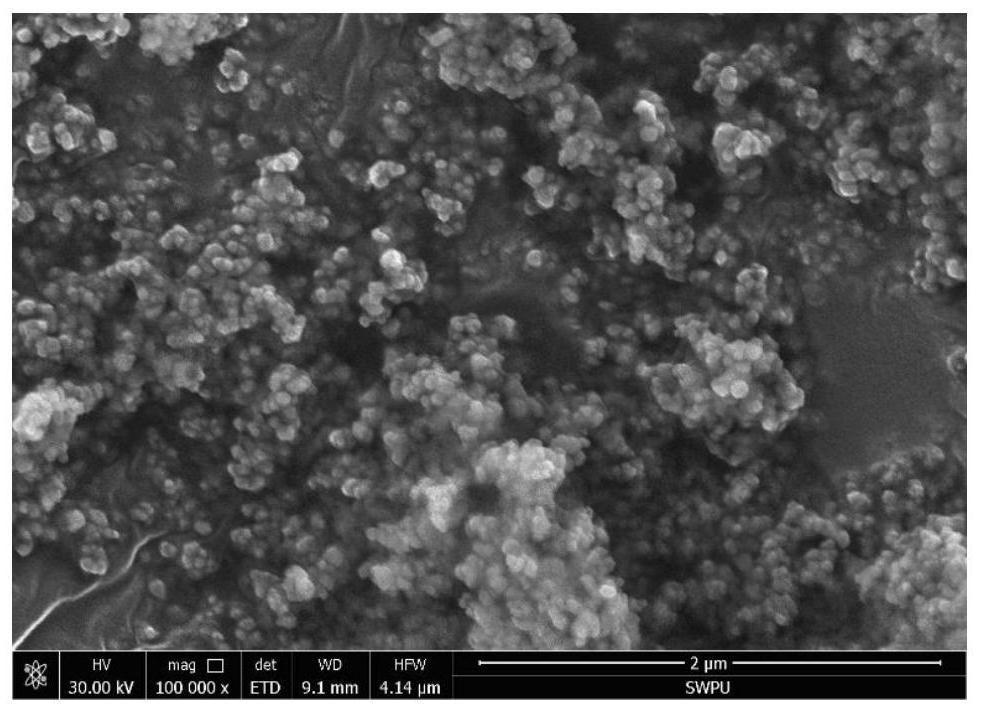

[0039] Prepare 500ml of yttrium nitrate aqueous solution of 0.2mol / L; Prepare the composite precipitation agent solution 500ml of triethanolamine and ammonium bicarbonate, wherein the concentration of ammonium bicarbonate is 0.3mol / L, the total number of moles of triethanolamine and ammonium bicarbonate and nitric acid The molar ratio of yttrium is 3:1; The compound precipitant solution is added dropwise in the yttrium nitrate aqueous solution with the speed of 8ml / min, stirs while adding dropwise, and stirring speed is 65rpm, after the compound precipitant solution is added dropwise After continuing to stir at a speed of 65rpm for 30min, stop stirring, leave the resulting mixture at room temperature for 8h, then filter the mixture with suction to obtain a precipitate of yttrium; wash the precipitate of yttrium with deionized water 3 times, Then washed twice with absolute ethanol, dried in a drying oven at 90 °C for 8 h after washing to obtain the yttrium oxide precursor; final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com