Light mullite-aluminum oxide hollow sphere-aluminum titanate sagger casting molding process

A technology of alumina hollow spheres and lightweight mullite, which is applied in the field of refractory materials, can solve problems such as instability and short service life, and achieve the effects of increasing service life, improving thermal shock resistance, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

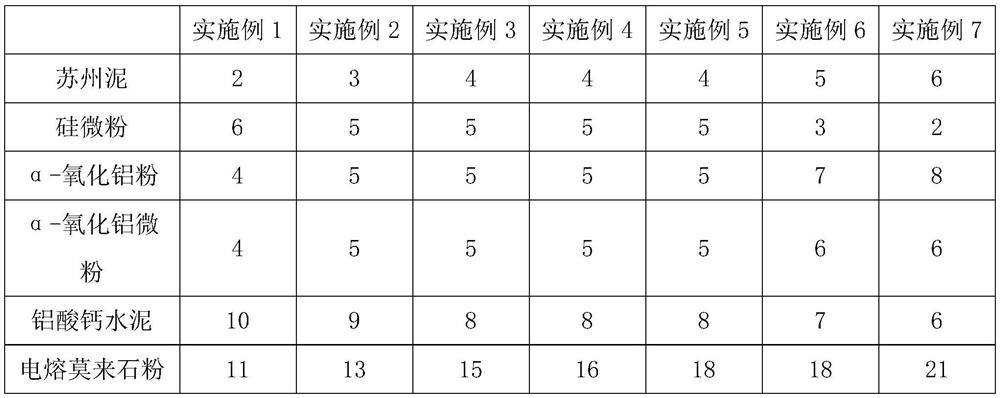

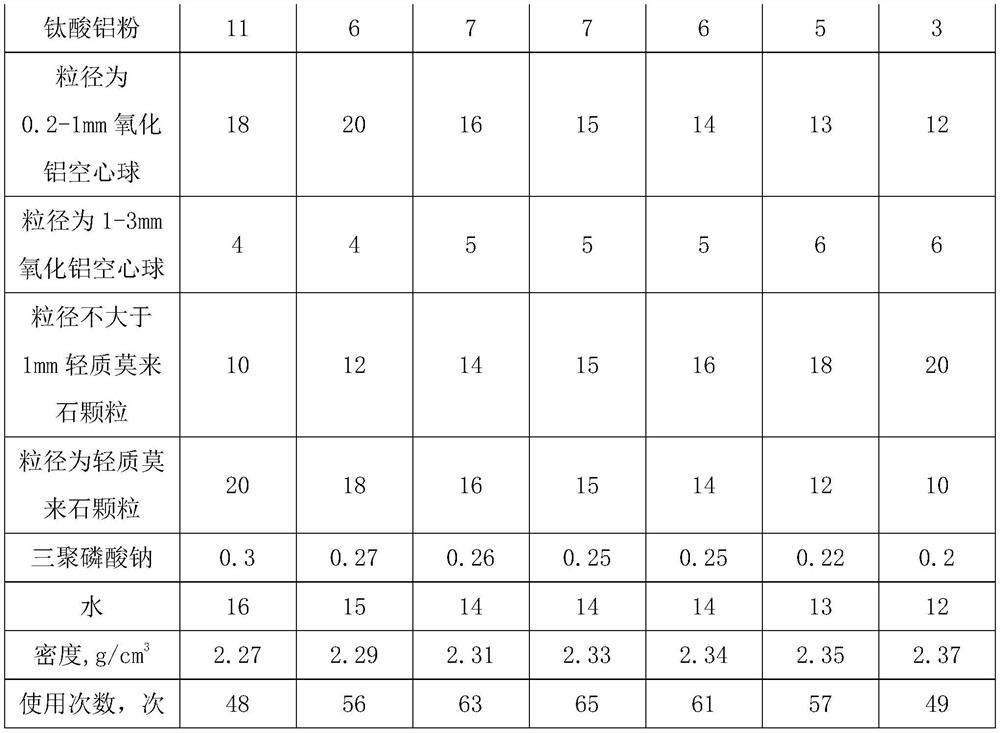

[0028] The invention provides a lightweight mullite-alumina hollow sphere-aluminum titanate sagger pouring molding process. In parts by weight, 2 parts of Suzhou No. 2 mud, 6 parts of silicon micropowder, and α-alumina powder are weighed. 4 parts, 4 parts of α-alumina micropowder, 10 parts of calcium aluminate cement, 11 parts of fused mullite powder, 11 parts of aluminum titanate powder, 18 parts of alumina hollow spheres with a particle size of 0.2-1mm, with a particle size of 4 parts of alumina hollow spheres of 1-3 mm, 10 parts of light mullite particles with a particle size of not more than 1 mm, 20 parts of light mullite particles with a particle size of 1-3 mm, 0.3 parts of sodium tripolyphosphate, put Put it into the mixer and mix it well, add 16 parts of water, and form a viscoplastic slurry with a certain fluidity after full stirring, pour the slurry into the mold, and put it on a vibration table or use a plug-in vibrator or a flat plate The vibrator, through vibrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com