High-temperature-resistant transition metal high-entropy oxide wave-absorbing filler and preparation method thereof

A transition metal and wave-absorbing filler technology, applied in the field of high-temperature-resistant high-entropy oxides and their preparation, can solve the problems of insufficient microwave loss capacity and single loss mode, and achieve excellent high temperature resistance and oxidation resistance, and high powder purity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

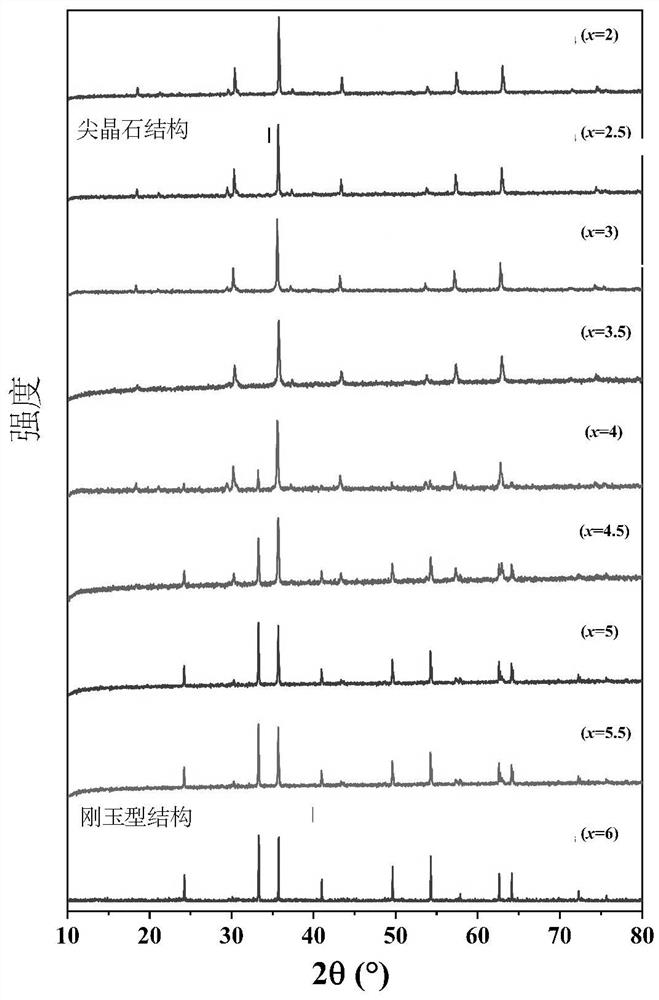

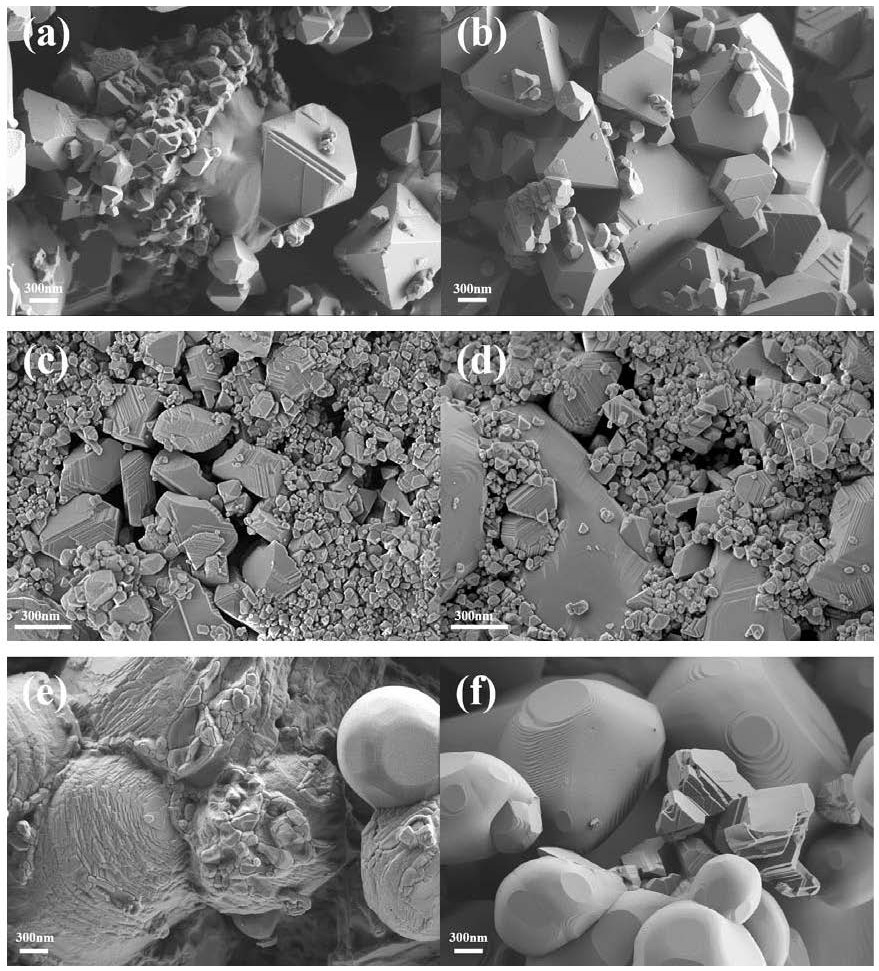

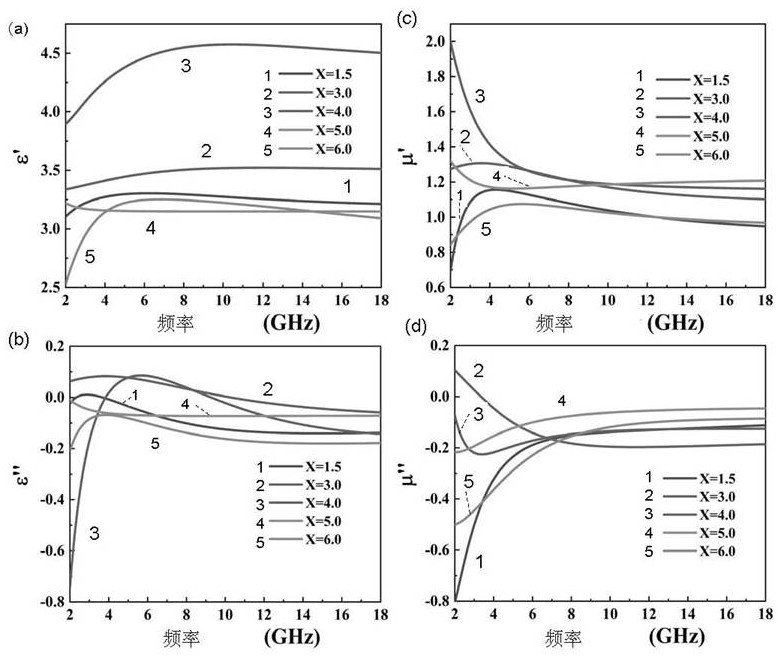

[0043] With Fe(NO 3 ) 3 9H 2 O particles, Co(NO 3 ) 2 ·6H 2 O particles, NiSO 4 ·6H 2 O particles, Cr(NO 3 ) 2 9H 2 O particles, MnSO 4 ·H 2 O powder is reactant, K 2 CO 3 1.5H 2 O powder is a precipitant, which is dissolved in deionized water and stirred until completely dissolved. The molar concentration ratio of cations (Fe ions: Co ions: Ni ions: Cr ions: Mn ions) in the reactants is x:1:1 :1:1 (1≤x≤6), the gradient interval of the Fe content of the components is 0.5, the total cation concentration in the reactant solution is 0.1mol / L, and the concentration of the precipitant solution is 0.15mol / L. Add the reactant solution dropwise to the precipitant solution at a rate of 40ml / min, keep stirring for 4 hours, then let it stand for 24 hours, pour off the supernatant, and centrifuge the precipitate (speed 7000rpm) to obtain high entropy Oxide precursor; place the precursor in an oven at 80°C (air atmosphere) to dry for 12 hours, then grind the dried sample int...

Embodiment 2

[0051] With Fe(NO 3 ) 3 9H 2 O particles, Co(NO 3 ) 2 ·6H 2 O particles, NiSO 4 ·6H 2 O particles, Cr(NO 3 ) 2 9H 2 O particles, MnSO 4 ·H 2 O powder is reactant, K 2 CO 3 1.5H 2 O powder is a precipitant, which is dissolved in deionized water and stirred until completely dissolved. The molar concentration ratio of cations in the reactant is 1:1:1:1:1, and the total cation concentration in the reactant solution is 0.1mol / L, the concentration of precipitant solution is 0.15mol / L. With the rate of addition of 40ml / min, the reactant solution was added dropwise in the precipitating agent solution, kept stirring for 4 hours, then left standstill for 24 hours, poured off the supernatant, and the precipitate was subjected to centrifugal filtration (speed 7000rpm) to obtain high Entropy oxide precursor; place the precursor in an oven at 80°C (air atmosphere) to dry for 12 hours, then grind the dried sample into powder, place it in Al 2 o 3 crucible, then put the cruc...

Embodiment 3

[0054] With Fe(NO 3 ) 3 9H 2 O particles, Co(NO 3 ) 2 ·6H 2 O particles, NiSO 4 ·6H 2 O particles, Cr(NO 3 ) 2 9H 2 O particles, MnSO 4 ·H 2 O powder is reactant, K 2 CO 3 1.5H 2 O powder is a precipitant, which is dissolved in deionized water and stirred until completely dissolved. The molar concentration ratio of cations in the reactant is 4:1:1:1:1, and the total cation concentration in the reactant solution is 0.1 mol / L, the concentration of precipitant solution is 0.15mol / L. With the rate of addition of 40ml / min, reactant solution was added dropwise in precipitant solution, kept stirring for 4 hours, then left standstill for 24 hours, poured off supernatant, precipitate was carried out centrifugation (speed 7000rpm), obtained high Entropy oxide precursor; place the precursor in an oven at 80°C (air atmosphere) to dry for 12 hours, then grind the dried sample into powder, place it in Al 2 o 3 Put the crucible into a tube furnace, raise the temperature to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com