Deep-layer active micro-powder masterbatch for moisture-proof building ground floor

A technology of active micropowder and masterbatch, which is applied in the field of building moisture-proof materials, can solve the problems that the density of the waterproof layer is difficult to prevent the passage of water vapor, the moisture-proof effect cannot be obtained, and the moisture-proof and waterproof are confused, so as to change the common problem of easy cracking and better prevent siphon. , The effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

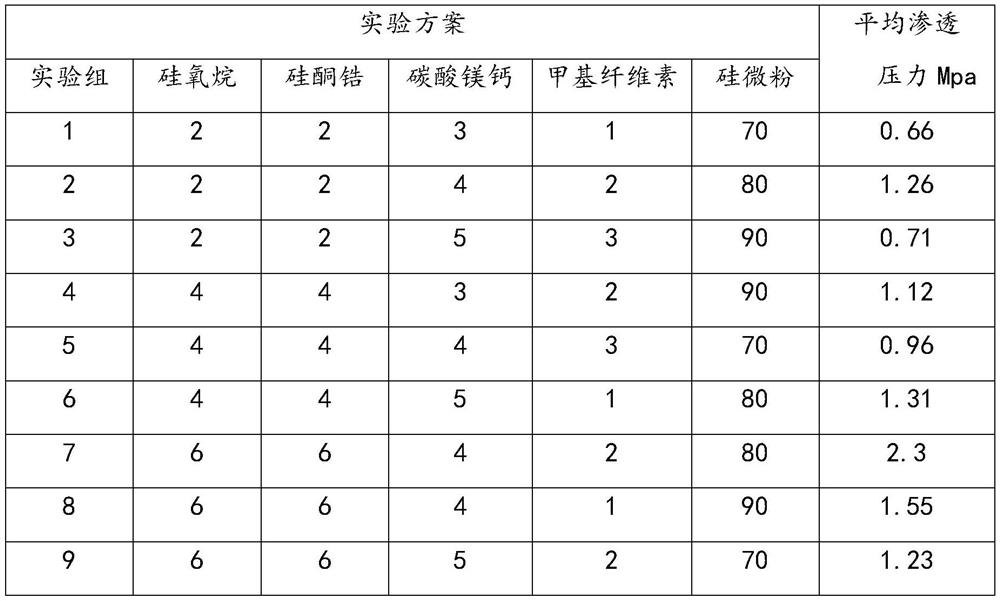

[0015] A moisture-proof deep active micropowder masterbatch for building ground floor, comprising the following components in parts by weight: 6 parts of acrylic polysiloxane, 6 parts of active silicone zirconium, 4 parts of magnesium calcium carbonate, 2 parts of methyl cellulose parts, 80 parts of 3000-mesh ultrafine silicon powder, 0.2 part of sodium silicate, 0.6 part of swelling agent, 0.3 part of water reducing agent, and 0.5 part of defoaming agent. Among them, the expansion agent adopts calcium sulfoaluminate type concrete expansion agent that does not contain sodium salt and will not cause concrete alkali aggregate reaction. The water reducing agent adopts modified calcium lignosulfonate (GCL1) superplasticizer.

Embodiment approach 2

[0017] A moisture-proof deep active micropowder masterbatch for building ground floor, comprising the following components in parts by weight: 6 parts of acrylic polysiloxane, 6 parts of active silicone zirconium, 4 parts of magnesium calcium carbonate, and 1 part of methyl cellulose parts, 90 parts of 3000-mesh ultrafine silicon powder, 0.1 part of sodium silicate, 0.8 part of swelling agent, 0.5 part of water reducing agent, and 0.5 part of defoaming agent. Among them, the expansion agent adopts calcium sulfoaluminate type concrete expansion agent that does not contain sodium salt and will not cause concrete alkali aggregate reaction. The water reducing agent adopts modified calcium lignosulfonate (GCL1) superplasticizer.

Embodiment approach 3

[0019] A moisture-proof deep active micropowder masterbatch for building ground floor, comprising the following components in parts by weight: 6 parts of acrylic polysiloxane, 6 parts of active silicone zirconium, 5 parts of magnesium calcium carbonate, 2 parts of methyl cellulose parts, 70 parts of 3000-mesh ultrafine silicon powder, 1 part of sodium silicate, 0.5 part of swelling agent, 0.3 part of water reducing agent, and 0.8 part of defoaming agent. Among them, the expansion agent adopts calcium sulfoaluminate type concrete expansion agent that does not contain sodium salt and will not cause concrete alkali aggregate reaction. The water reducing agent adopts modified calcium lignosulfonate (GCL1) superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com