Graphite electrode end flattening device and method

A technology of graphite electrode and flat head, which is applied to grinding drive devices, machine tools suitable for grinding workpiece planes, grinding machines, etc. It can solve the problems of affecting normal work, large operating errors, and changes in the tightness of steel wire ropes, and achieves convenient length adjustments in time , The overall structure design is compact, and the effect of solving the inconvenience of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

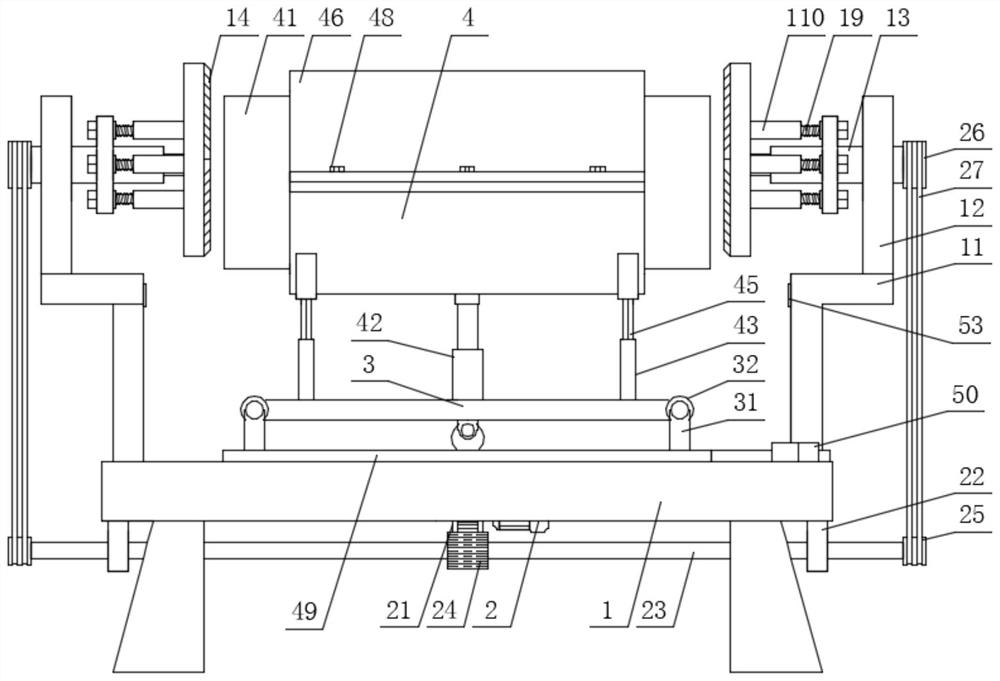

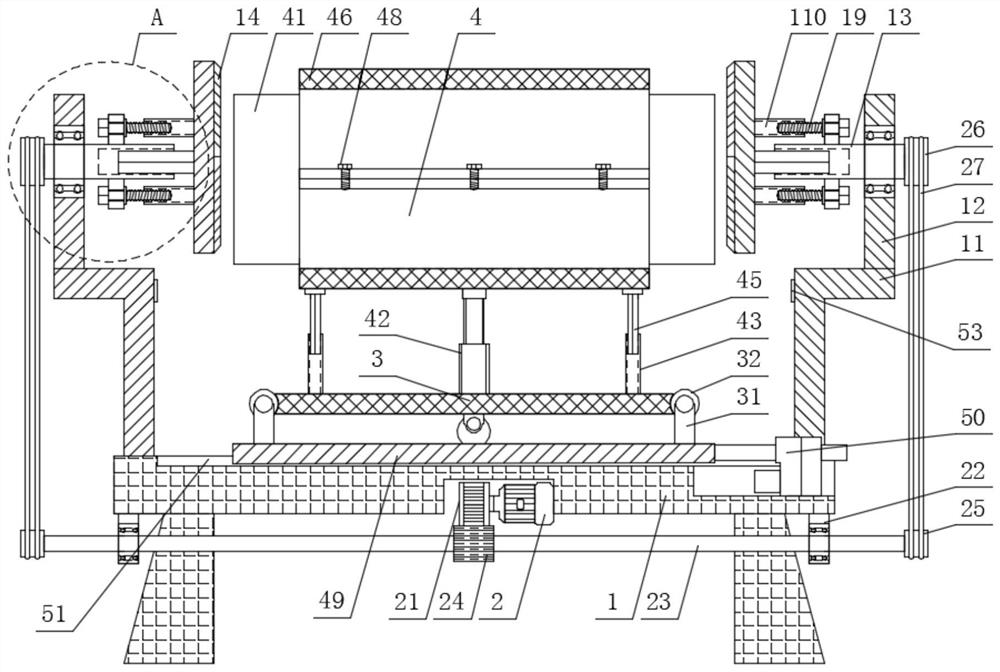

[0041] Embodiment 1: This embodiment provides a graphite electrode flat head device, see Figure 1-5 Specifically, it includes a base plate 1, a sliding mechanism, a lifting mechanism, and a driving mechanism. The base plate 1 is a rectangular plate placed horizontally and horizontally. The middle part of the top surface of the base plate 1 is provided with a horizontal plate 3 placed horizontally. The mechanism is connected with the bottom plate 1, and the top of the horizontal plate 3 is provided with a horizontally placed semicircular clamp 4, and the semicircular clamp 4 is provided with a horizontally placed graphite electrode 41, and the horizontal plate 3 is connected with the semicircular clamp 4 through a lifting mechanism;

[0042] Both sides of the top surface of the bottom plate 1 are provided with a pair of symmetrically fixed L-shaped plates 11, and the outer sides of the top surface of each L-shaped plate 11 are provided with vertically fixed side plates 12, and ...

Embodiment 2

[0051] Embodiment 2: In Embodiment 1, there is also the problem that the graphite electrode is not firmly fixed during processing. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0052] In the present invention, a movable hinged semicircle cover plate 46 is provided on the rear side of the top surface of the semicircle clamp 4, and a semicircle rubber pad 47 is provided on the inner wall of the semicircle cover plate 46 and the semicircle clamp 4, and two semicircle rubber pads are provided. The pads 47 are pressed against the upper and lower sides of the graphite electrode 41 respectively, and the front side of the semicircle cover plate 46 is evenly provided with some fastening bolts 48 that penetrate through the spiral. Side screw locking; center the graphite electrode 41 that needs to be polished flat on the semicircle clamping plate 4, cover the semicircle cover plate 46, and screw the fastening bolts 48 respectively, the inner ends of each fasten...

Embodiment 3

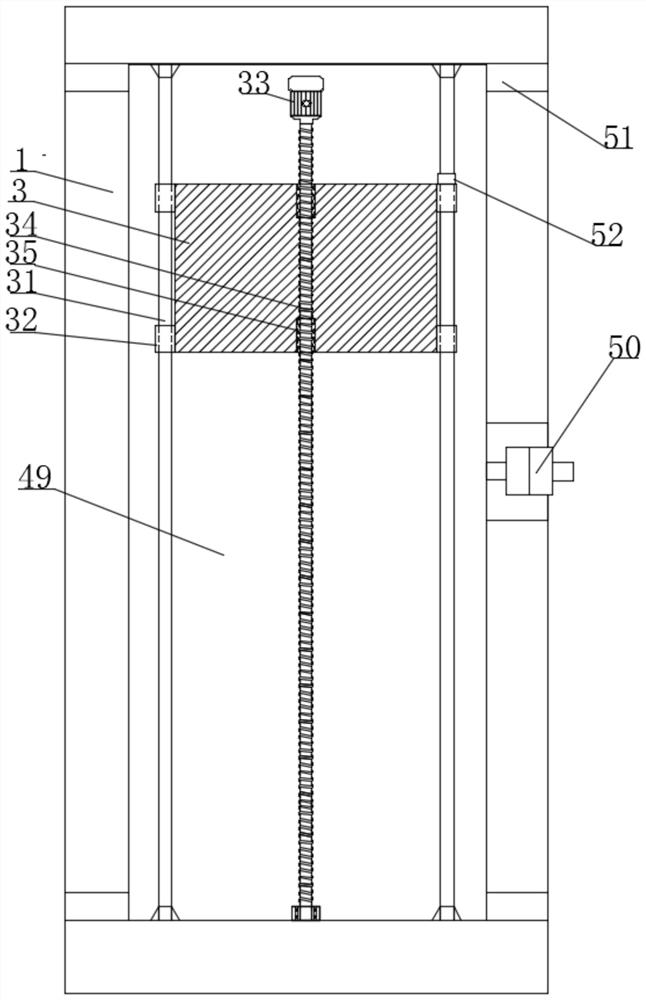

[0053] Embodiment three: see Image 6 , in the present embodiment, the present invention also proposes a method for using a graphite electrode flat head device, comprising the following steps:

[0054] Step 1, drive motor 2, sliding motor 33, linear motor 50, and hydraulic cylinder 42 are electrically connected to external power supply respectively through power line, according to the length of graphite electrode 41, adjust the distance between two flat-head grinding discs 14, through the rotating tool The word shaft 18 drives the screw rod 19 to cooperate with the threaded cylinder 110 to spirally rotate, and then drives the square rod 16 to slide outward or inward along the square groove 15, thereby changing the distance between the two flat-headed grinding discs 14;

[0055] Step 2, center the graphite electrode 41 that needs to be polished flat on the semicircle clamp 4, cover the semicircle cover 46, and screw the fastening bolts 48 respectively, the inner ends of each fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com