Machining method of tapered roller for rail transit

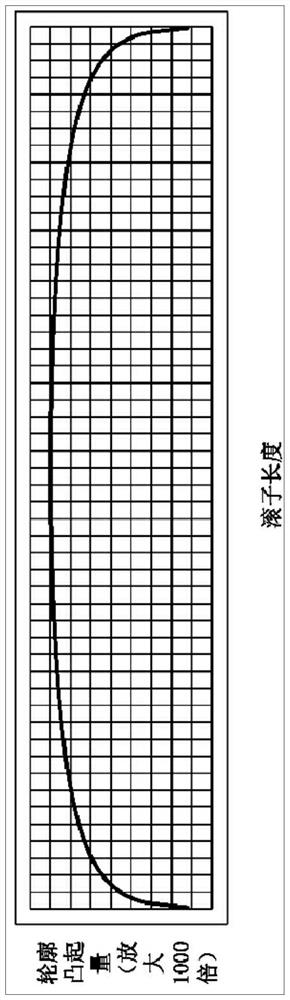

A technology of tapered rollers and processing methods, which is applied in the direction of metal processing equipment, manufacturing tools, and the control of workpiece feed movement, etc. It can solve problems such as poor consistency of dimensional accuracy, and the radian of the rolling surface contour cannot meet the requirements, etc., to achieve temperature rise small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

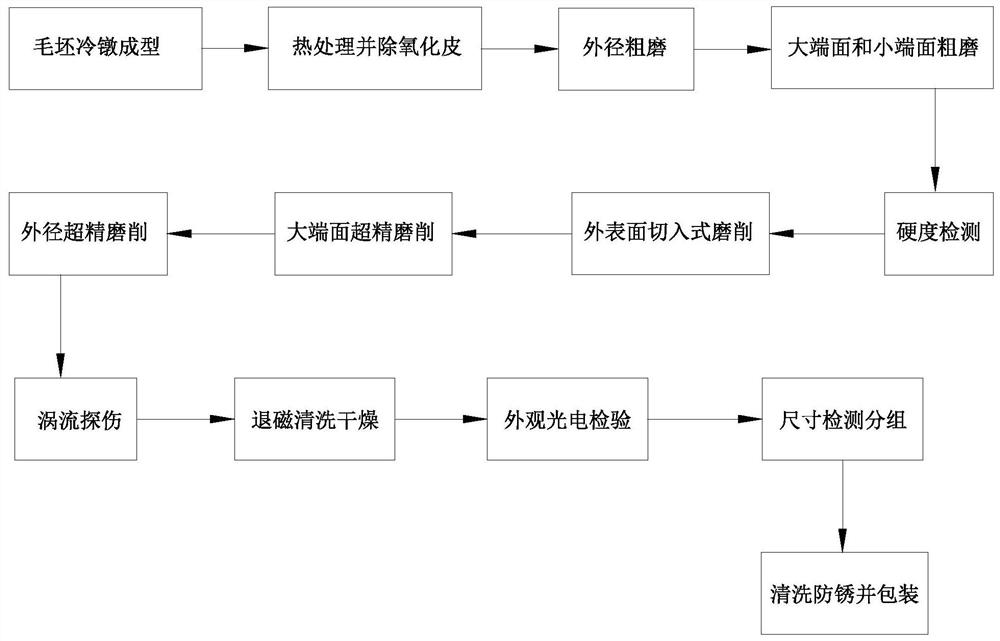

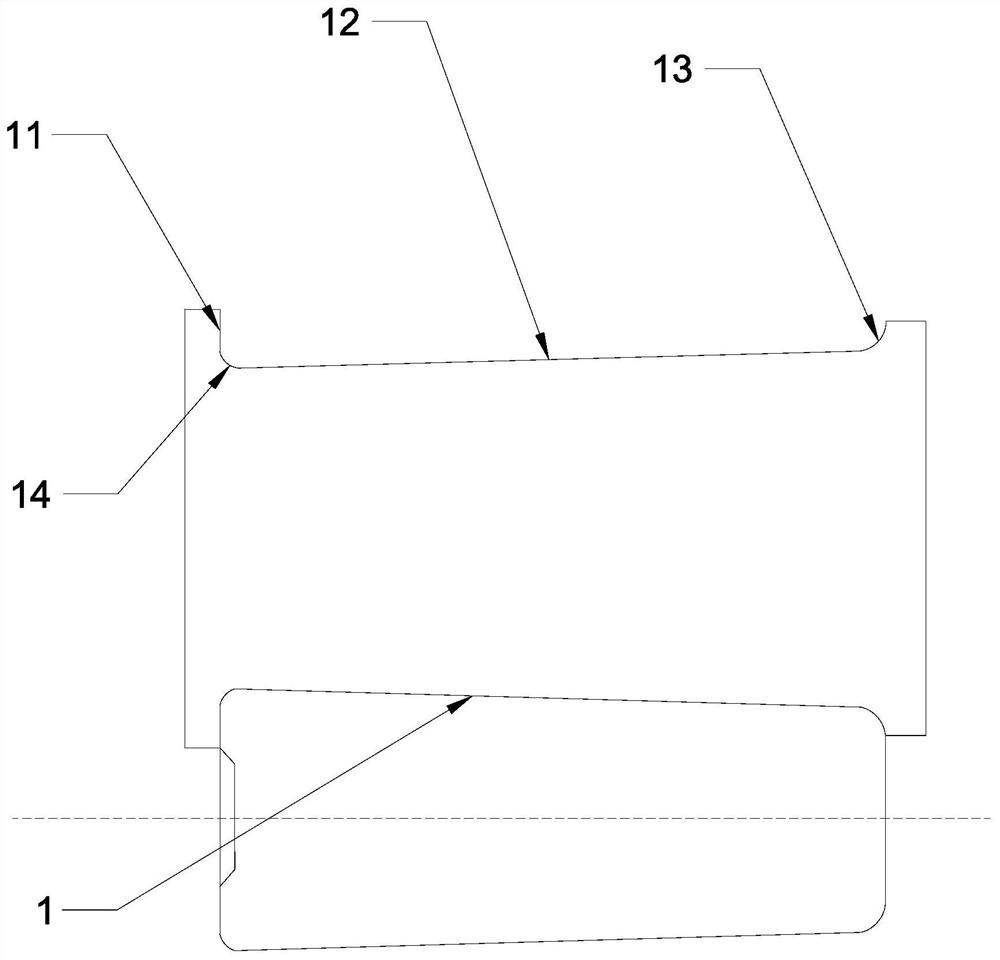

[0013] An embodiment of a tapered roller processing method for rail transit of the present invention is as follows Figure 1-3 As shown, when processing rollers with a diameter below 15mm, the following steps are included:

[0014] (1) The American national cold heading machine RH161 is used to form the roller blank at one time by cold heading;

[0015] (2) Heat-treat the formed roller blank and remove the oxidized skin;

[0016] (3) The 3MK6040 model grinding machine equipped with CBN grinding wheel is used to carry out through-type centerless grinding of the rollers, complete the rough grinding of the outer diameter of the rollers, and eliminate the outer diameter allowance of the rollers. Grinding;

[0017] (4) Use the MK7730 type grinding machine equipped with CBN grinding wheel to carry out rough grinding on the large end face and small end face of the roller, and grind the allowance of the small end face to solve the weight consistency caused by the small end face betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com