A kind of preparation method of medical dressing with drug-loading function

A functional and drug-loading technology, which is applied in the fields of pharmaceutical formulation, drug delivery, and medical science, can solve the problems that the hemostatic dressing cannot quickly and completely stop bleeding, has no obvious promotion effect on wound healing, and has poor barrier effect, so as to improve the drug loading capacity , promote wound healing, increase the effect of adhesion sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

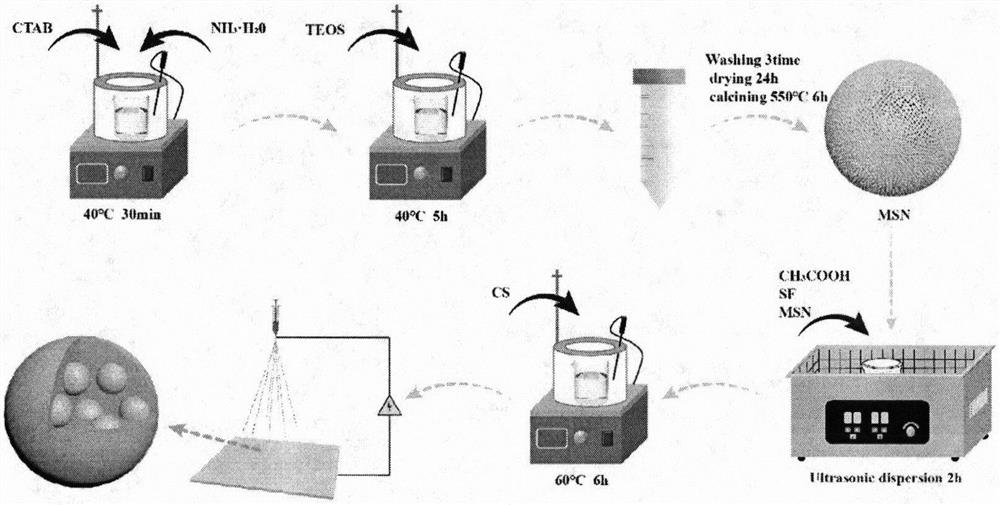

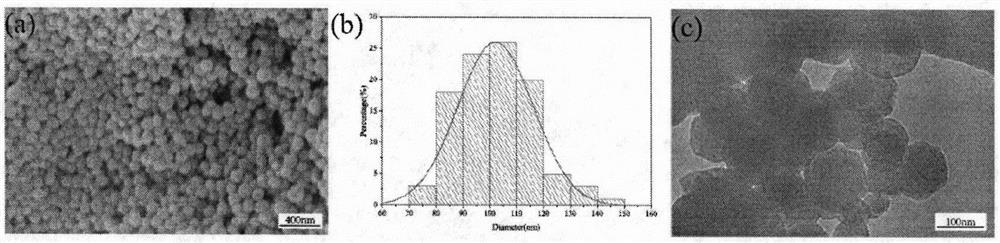

[0042] 1) First dissolve 0.32g of cetyltrimethylammonium bromide (CTAB) in 280ml of deionized water, stir for 30 minutes, slowly drop 8ml of ammonia water, then heat in a water bath at 40°C and stir for 30 minutes. Finally, 2.44 ml of ethyl orthosilicate (TEOS) was added and stirred for 5 h. The turbid liquid was centrifuged in a centrifuge to obtain a white moist powder, which was washed three times with 75% ethanol solution. After centrifugation, it was placed in an oven at 70°C to dry. Finally, the white solid was mashed and calcined in a muffle furnace for 6 hours. After taking out the white powder, continue grinding to obtain mesoporous nano-silica (MSN).

[0043] 2) Mix 10% silk fibroin (SF) aqueous solution with 90% acetic acid in a mixing ratio of 10:90. An additional 2.0% chitosan (CS) was added. SF / CS microspheres were prepared.

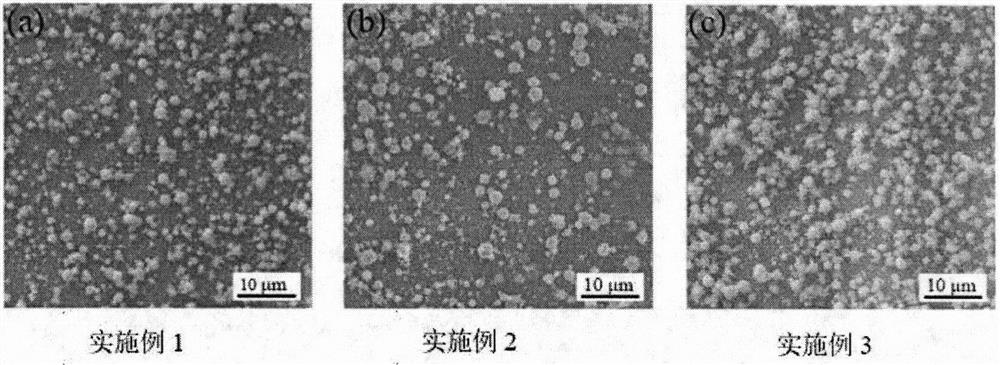

[0044] 3) Mix 10% SF aqueous solution and 90% acetic acid solution in a ratio of 10:90, add 5% MSN (MSN / CS=5wt%), and sonicate for 2h...

Embodiment 2

[0046] 1) First dissolve 0.32g of cetyltrimethylammonium bromide (CTAB) in 280ml of deionized water, stir for 30 minutes, slowly drop 8ml of ammonia water, then heat in a water bath at 40°C and stir for 30 minutes. Finally, 2.44 ml of ethyl orthosilicate (TEOS) was added and stirred for 5 h. The cloudy liquid was centrifuged in a centrifuge to obtain a white moist powder, which was washed three times with 75% ethanol solution. After centrifugation, it was placed in an oven at 70°C to dry. Finally, the white solid was mashed and calcined in a muffle furnace for 6 hours. After taking out the white powder, continue grinding to obtain mesoporous nano-silica (MSN).

[0047] 2) Mix 10% silk fibroin (SF) aqueous solution with 90% acetic acid in a mixing ratio of 10:90, and then add 2% chitosan (CS). SF / CS microspheres were prepared.

[0048]3) Mix 10% SF aqueous solution and 90% acetic acid solution in a ratio of 10:90, add 10% MSN (MSN / CS=10wt%), and sonicate for 2h. Then 2.0% ...

Embodiment 3

[0050] 1) First, dissolve 0.32g of cetyltrimethylammonium bromide (CTAB) in 280ml of deionized water, stir for 30 minutes, slowly drop 8ml of ammonia water, then heat in a water bath at 40°C and stir for 30 minutes. Finally, 2.44 ml of ethyl orthosilicate (TEOS) was added and stirred for 5 h. The turbid liquid was centrifuged in a centrifuge to obtain a white moist powder, which was washed three times with 75% ethanol solution. After centrifugation, it was placed in an oven at 70°C to dry. Finally, the white solid was mashed and calcined in a muffle furnace for 6 hours. After taking out the white powder, continue grinding to obtain mesoporous nano-silica (MSN).

[0051] 3) Mix 10% silk fibroin (SF) aqueous solution with 90% acetic acid in a mixing ratio of 10:90, and then add 2% chitosan (CS). SF / CS microspheres were prepared.

[0052] 3) Mix 10% SF aqueous solution and 90% acetic acid solution in a ratio of 10:90, add 15% MSN (MSN / CS=15wt%), and sonicate for 2h. Then 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com