Base solution composition of chemical rubber plug, chemical rubber plug composition, chemical rubber plug and application process of chemical rubber plug

A technology of composition and chemical glue, which is applied in the direction of drilling composition, chemical instruments and methods, wellbore/well components, etc., can solve the problems of artificial fracture height and shape development that cannot be fractured efficiently, and achieve height and Efficient control of morphological development, improvement of plugging effect and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

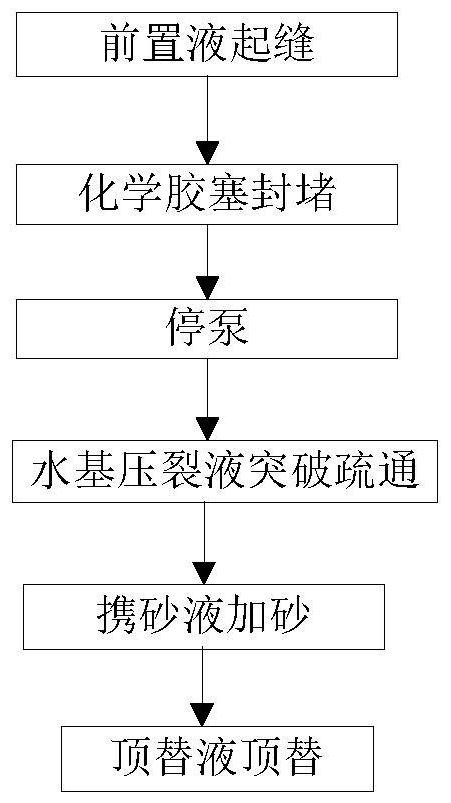

Method used

Image

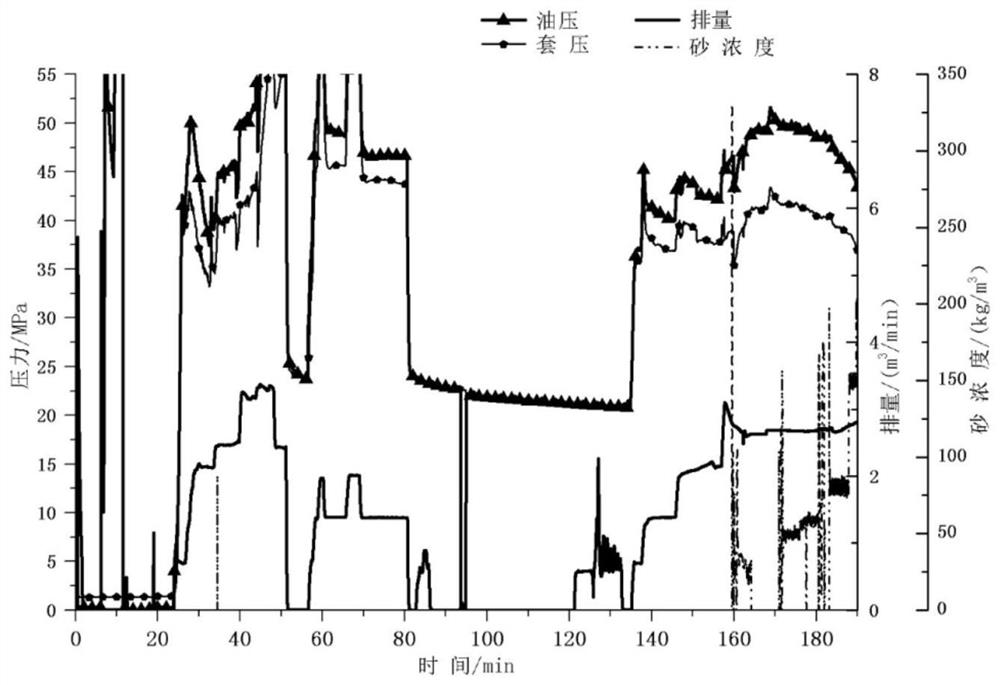

Examples

Embodiment 1

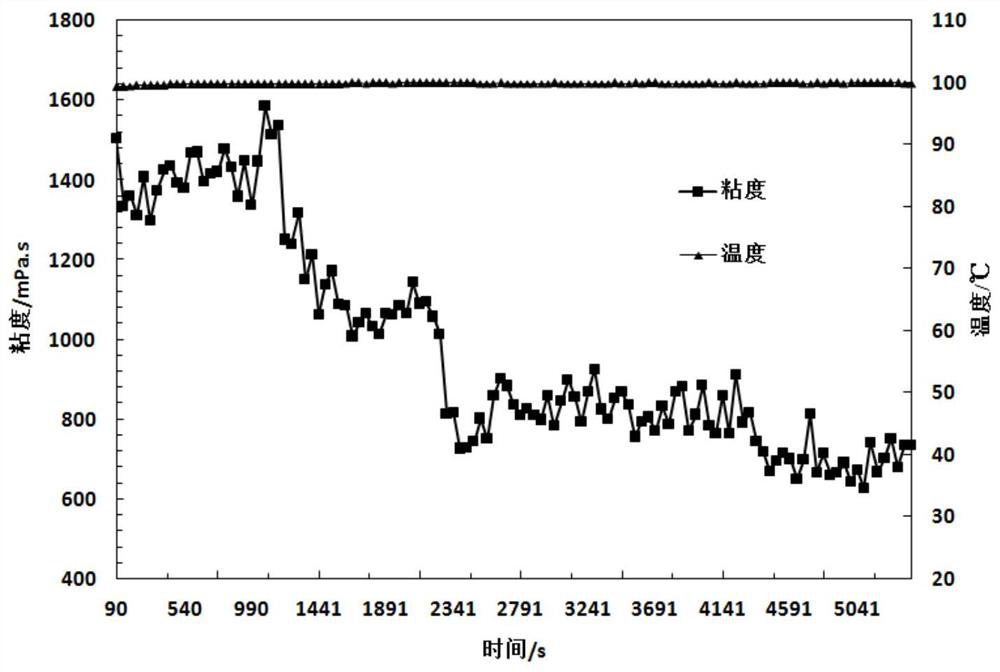

[0059] 0.005 part of sodium gluconate, 0.5 part of hydroxypropyl guar gum, 98 parts of water, 0.1 part of inorganic clay anti-swelling agent, 0.1 part of polyoxyethylene polyoxypropylene polyether, 0.1 part of fluorocarbon surface active The agent was stirred, the stirring speed was 1500r / min, and the stirring time was 8min to obtain the base liquid composition of the chemical rubber stopper.

Embodiment 2

[0061] With 0.05 parts of sodium gluconate, 0.8 parts of hydroxypropyl guar gum, 98.5 parts of water, 3 parts of inorganic clay anti-swelling agent, 0.5 parts of polyoxyethylene polyoxypropylene polyether, 0.5 parts of fluorocarbon surface active The agent was stirred, the stirring speed was 1500r / min, and the stirring time was 8min to obtain the base liquid composition of the chemical rubber stopper.

Embodiment 3

[0063] 0.08 parts of sodium gluconate, 1.2 parts of hydroxypropyl guar gum, 99 parts of water, 6 parts of inorganic clay anti-swelling agent, 1 part of polyoxyethylene polyoxypropylene polyether, 1 part of fluorocarbon surface active The agent was stirred, the stirring speed was 1800r / min, and the stirring time was 15min to obtain the base liquid composition of the chemical rubber stopper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com