A kind of aqueous dispersant containing phosphoric acid group and its preparation method and application

A phosphoric acid-based water-based and dispersant technology, which is applied in applications, household utensils, inks, etc., to achieve the effects of improving compatibility, improving dispersion stability, grinding efficiency, and improving anti-sedimentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

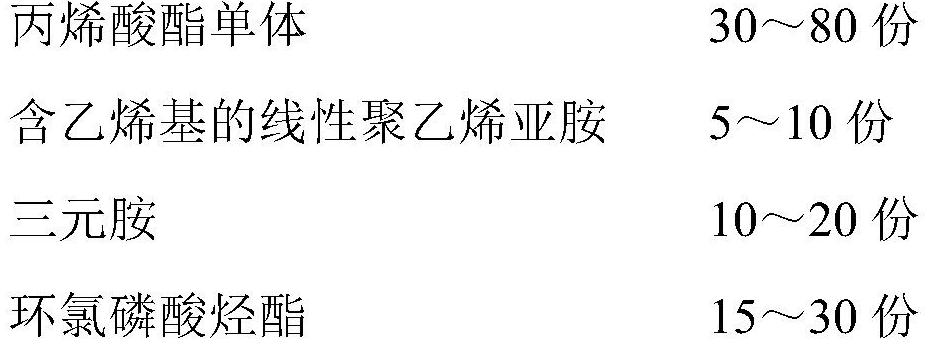

[0051] Preparation of Waterborne Dispersant Containing Phosphoric Acid

[0052] According to the parameters such as raw material composition and proportion in Table 2, a phosphoric acid-based aqueous dispersant was prepared.

[0053] The embodiment (unit: g) of table 2 aqueous dispersants

[0054]

Embodiment 1

[0056] S1. Ethyl methacrylate, tert-butyl methacrylate, hydroxyethyl acrylate, PEI-1 and 50 g of butyl acetate were uniformly mixed to obtain a mixed monomer.

[0057] S2. Add 300g of butyl acetate to the reaction kettle, add the mixed monomer obtained in step S1, raise the temperature to 70°C under a nitrogen atmosphere, add azobisisobutyronitrile and 1,1-diphenylethylene to react, and react for 5h. Intermediate 1 was obtained.

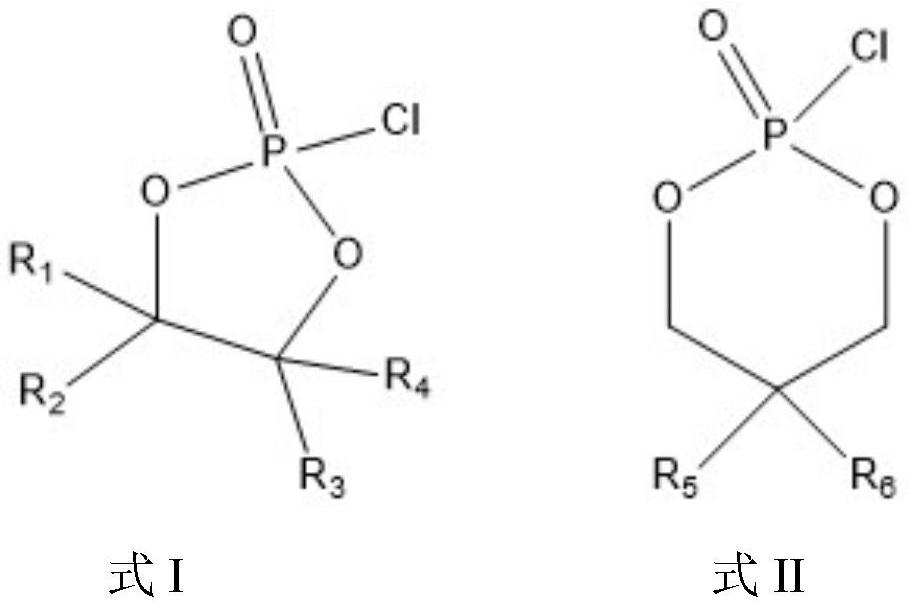

[0058] S3. Add 300g of dioxane to the reaction kettle, add intermediate 1 obtained in step S2, add triethylamine, stir for 2-3h; add 2-chloro-2-oxo-1,3,2-dioxaphospholane Alkanes, stirred at 70 ° C for 2d, and reacted to obtain intermediate 2.

[0059] S4. Add 300 mL of prepared hydrochloric acid solution (37% hydrochloric acid: dioxane: water = 3: 1: 1, v: v: v) into the reaction kettle, add intermediate 2 obtained in step S3, heat up to 80 ° C, and react for 5 h , to obtain a phosphoric acid-based aqueous dispersant.

Embodiment 2

[0061] S1. Ethyl methacrylate, tert-butyl methacrylate, hydroxyethyl acrylate, PEI-1 and 50 g of butyl acetate were uniformly mixed to obtain a mixed monomer.

[0062] S2. Add 300g of butyl acetate to the reaction kettle, add the mixed monomer obtained in step S1, raise the temperature to 70°C under a nitrogen atmosphere, add azobisisobutyronitrile and 1,1-diphenylethylene to react, and react for 5h. Intermediate 1 was obtained.

[0063] S3. Add 300g of dioxane to the reaction kettle, add intermediate 1 obtained in step S2, add triethylamine, stir for 2-3h; add 5,5-dimethyl-2-chloro-1,3,2-diox Phosphacaprolactoyl phosphate, stirred at 70°C for 2d, reacted to obtain intermediate 2.

[0064] S4. Add 300 mL of prepared hydrochloric acid solution (37% hydrochloric acid: dioxane: water = 3: 1: 1, v: v: v) into the reaction kettle, add intermediate 2 obtained in step S3, heat up to 80 ° C, and react for 5 h , to obtain a phosphoric acid-based aqueous dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity change rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com