Fucoxanthin composite nanofiber and preparation method thereof

A technology of composite nanofiber and fucoxanthin, which is applied in the field of food chemistry, can solve the problems of low oral utilization, poor stability, and limited application, and achieve the effects of low preparation cost, maintaining activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

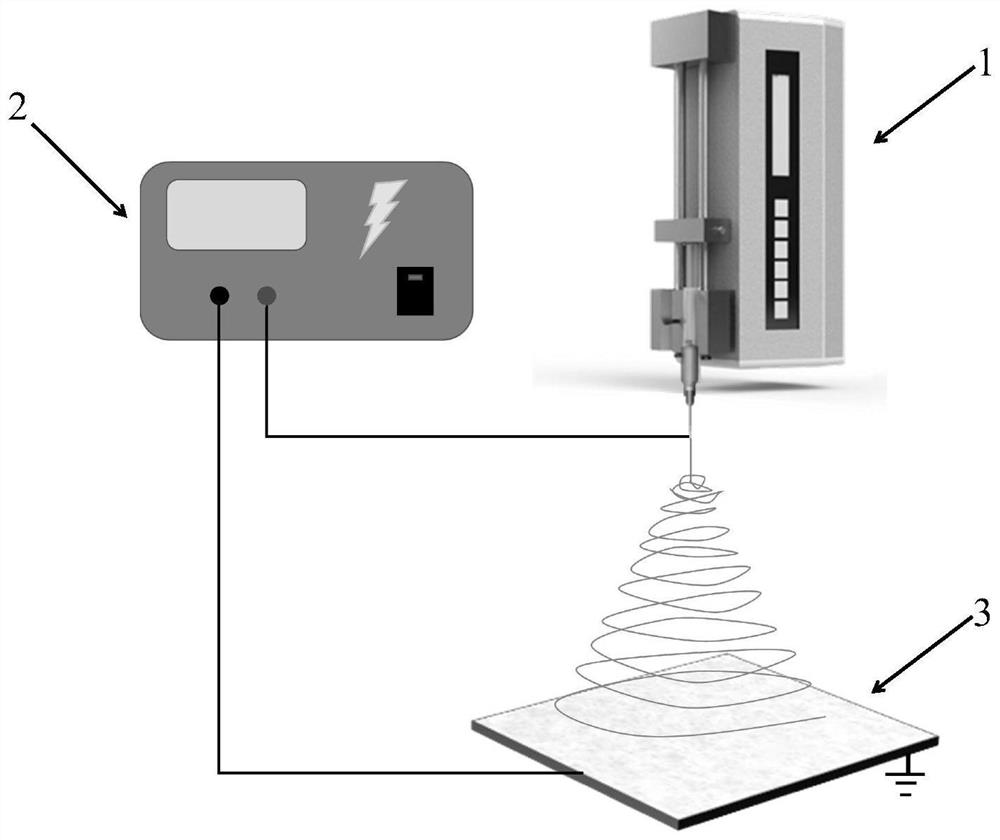

[0029] The preparation method of the fucoxanthin-cyclodextrin / polyvinylpyrrolidone nanofiber provided by the invention comprises:

[0030] Step 1: Dissolve the cyclodextrin powder in water, dissolve the fucoxanthin in the organic reagent, stir at room temperature at a speed of 200rpm / min for 4h until uniform, and then stir the fucoxanthin at a speed of 200rpm / min The plain organic solvent was added dropwise into the cyclodextrin aqueous solution at a rate of 1-5ml / min and mixed thoroughly for 2 hours. A fucoxanthin-cyclodextrin solution is obtained by linking the hydrophobic inner cavity of the cyclodextrin with the fucoxanthin. Wherein the molar ratio of fucoxanthin organic solution and cyclodextrin aqueous solution is 1: (1~2), the mass volume fraction of salicoxanthin in solvent is 4~20%; The organic solvent that fucoxanthin is dissolved in is none Water ethanol, edible glycerin and other polar organic solvents.

[0031] Step 2: Weigh polyvinylpyrrolidone and add it to th...

Embodiment 1

[0034] Weigh 0.5g of cyclodextrin and dissolve in water, weigh 0.42g of fucoxanthin and dissolve in absolute ethanol, and stir at 200rpm / min at room temperature for 4h respectively. Then, under the state of magnetic stirring at the same rotational speed, the fucoxanthin organic solvent was added dropwise to the cyclodextrin aqueous solution at a speed of 1.5 ml / min and mixed thoroughly for 2 hours. Add 0.5 g of polyvinylpyrrolidone to the mixture, and stir at room temperature at a speed of 200 rpm / min until it is completely dissolved.

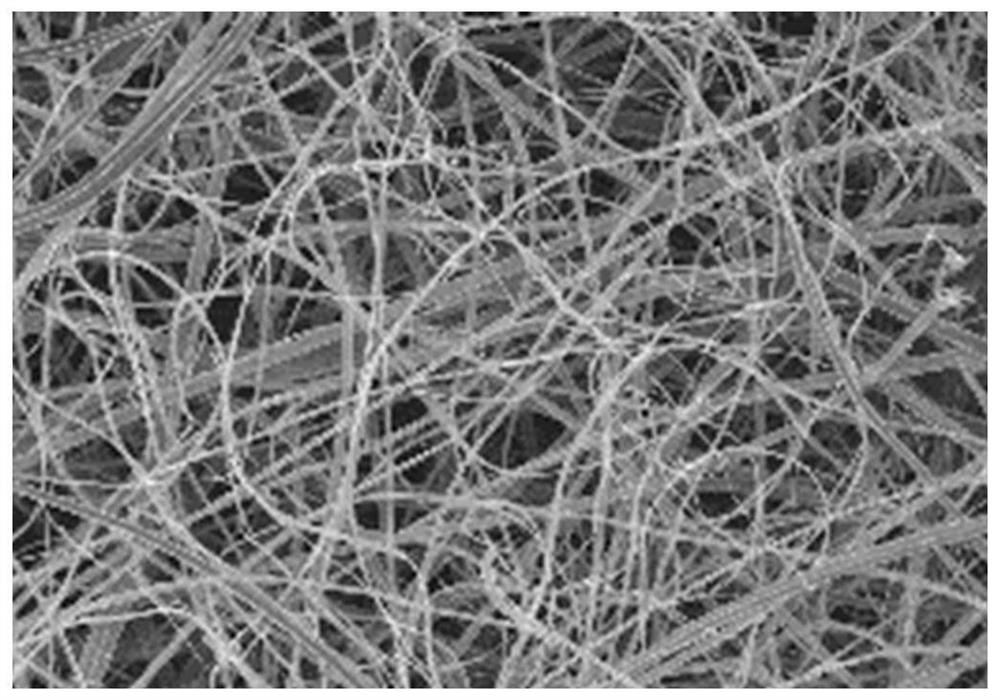

[0035] Inhale the prepared electrospinning solution into a 1ml syringe, select a 25G injection needle, connect it to the positive electrode of the high-voltage power supply, use aluminum foil as the receiving plane to connect the negative electrode, and use a syringe pump to control the injection flow rate of the electrospinning solution. Turn on the high-voltage power supply, adjust the flow rate of the syringe to 0.3ml / h, the receiving distan...

Embodiment 2

[0037] Weigh 0.75g of cyclodextrin and dissolve in water, weigh 0.16g of fucoxanthin and dissolve in absolute ethanol, and stir at 200rpm / min at room temperature for 4h respectively. Then, under the state of magnetic stirring at the same rotational speed, the fucoxanthin organic solvent was added dropwise to the cyclodextrin aqueous solution at a speed of 3 ml / min and mixed thoroughly for 2 hours. Add 0.5 g of polyvinylpyrrolidone to the mixture, and stir at room temperature at a speed of 200 rpm / min until it is completely dissolved.

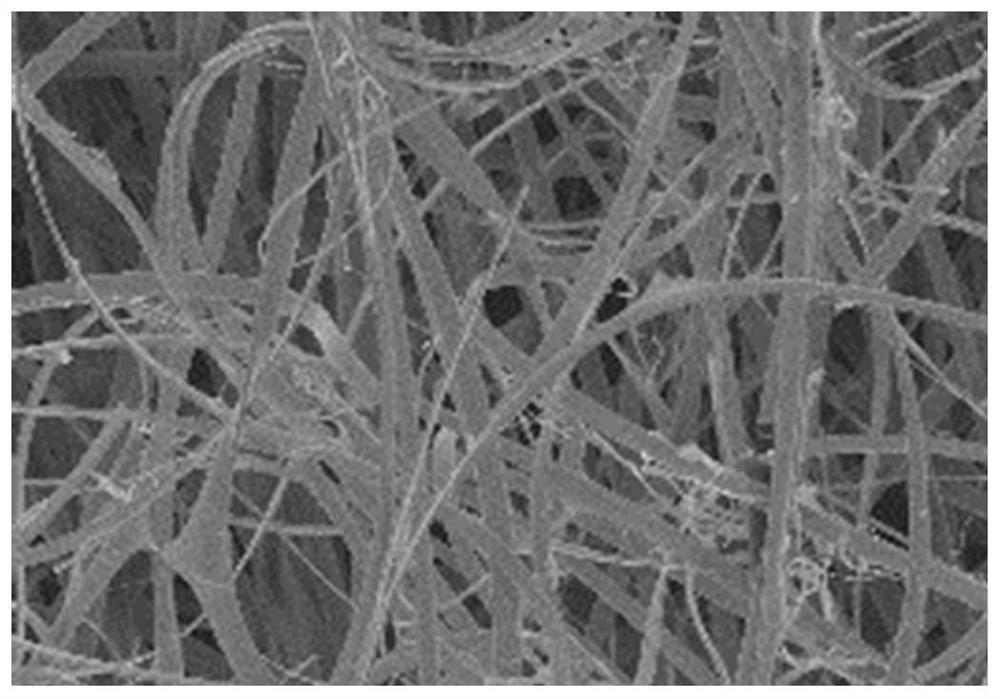

[0038] Inhale the prepared electrospinning solution into a 1ml syringe, select a 25G injection needle, connect it to the positive electrode of the high-voltage power supply, use aluminum foil as the receiving plane to connect the negative electrode, and use a syringe pump to control the injection flow rate of the electrospinning solution. Turn on the high-voltage power supply, adjust the flow rate of the syringe to 0.6ml / h, the receiving distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com