Equipment and process for preparing back passivation solar cell

A solar cell and back passivation technology, applied in the field of solar cells, can solve the problems of slow LPCVD coating rate, increased power consumption, high conductivity of amorphous/microcrystalline silicon film, and achieve film quality and passivation performance Excellent, reduce the ratio of high temperature deformation, save the effect of off-line doping equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

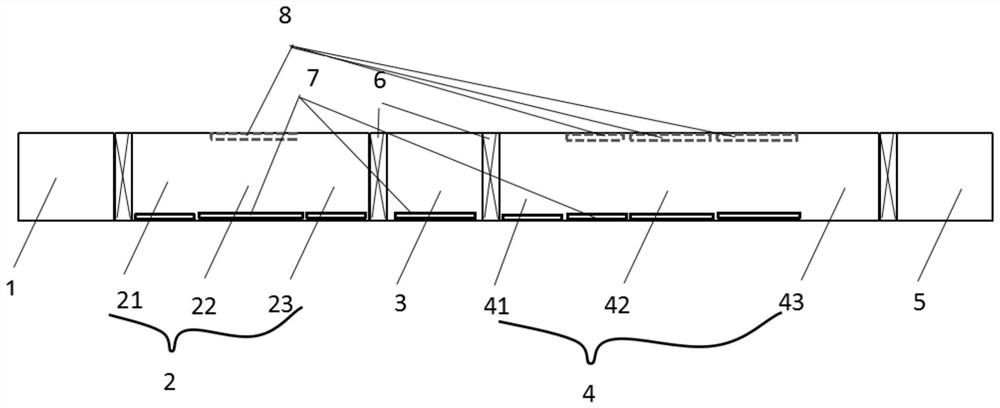

specific Embodiment 1

[0034] The tray is first introduced into the feeding chamber 11, and infrared lamps can be used to quickly heat the tray and silicon wafers, and then introduced into the first process chamber 2. The first process chamber 2 is composed of the first buffer chamber 21, the first coating chamber 22 and The second buffer chamber 23 is composed of three chambers, and the lower layer of the three chambers is covered with a heating plate 7, which can continuously heat the tray and silicon wafer. The tray enters the first buffer chamber 21 after being adjusted to the required process transmission speed. The first coating chamber 22, the first coating chamber 22 is provided with an upper electrode composed of a spray plate 8, the upper electrode is connected to a power supply, the frequency of the power supply is 40KHz-80MHz, and the spray plate 8 is provided with a plurality of uniformly distributed dense Exhaust holes, the process gas is evenly passed into the first coating chamber 22 ...

specific Embodiment 2

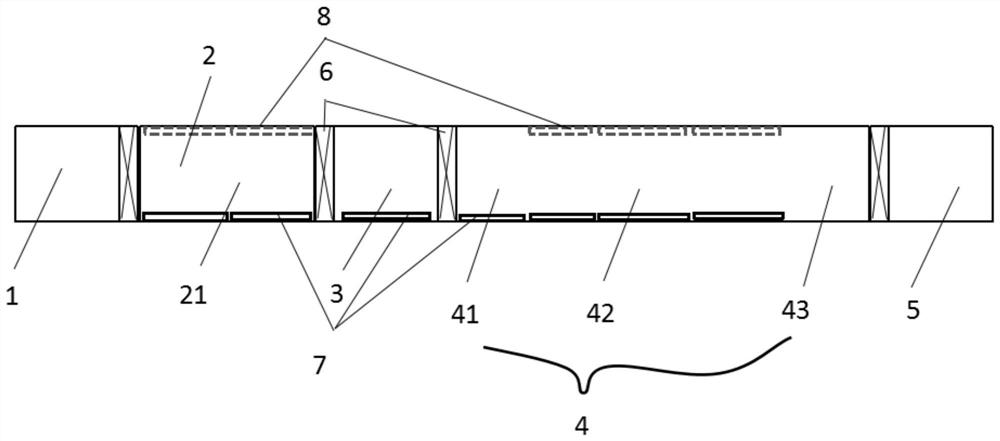

[0040] The structure and process flow of the first process chamber 2 in this embodiment are different from those in Embodiment 1, and the rest of the structure and process flow are consistent with Embodiment 1. The first process chamber 2 consists of n (n≥1) ALD or PEALD coating chambers Composed of 21 bodies, the lower side of the process chamber is covered with heating plates, the upper side of the coating chamber 21 is equipped with a gas spray plate or a plurality of pipeline inlets are arranged to replace the spray plate, and a vacuum pump is arranged in the cavity of the coating chamber 21 There are n trays (n n≥1) that can be placed on the air inlet and the lower heating plate. This process chamber is used to prepare an ultra-thin silicon dioxide film on the surface of the silicon wafer by atomic layer deposition (ALD). The material chamber 1 is then transferred to the first process chamber 2. After the first process chamber 2 is covered with pallets, the valves 6 on bot...

specific Embodiment 3

[0046] The process flow of the first process chamber 2 in this embodiment is different from that in Embodiment 1. The structure of the first process chamber 2 is consistent with that of the first process chamber in Embodiment 1, while the isolation chamber 3 and the second process chamber 4 are The structure and process flow are the same as those in Embodiment 1. The air extraction port is arranged on the lower side of the heating plate 7. There is a spray plate 8 on the upper side of the first coating chamber 22. Ozone is evenly introduced into the cavity through the pores of the spray plate 8, and the silicon The surface of the sheet is oxidized to silicon oxide, and the upper side of the first coating chamber 22 can also use a UV lamp to dissociate oxygen to form ozone. The formation of ozone can use an ozone generator or UV lamp to dissociate, etc., including but not limited to the above methods.

[0047] The first process chamber 2 can also adopt the method of static coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com