Process method and device for producing oil by pyrolysis of high-molecular polymerization waste

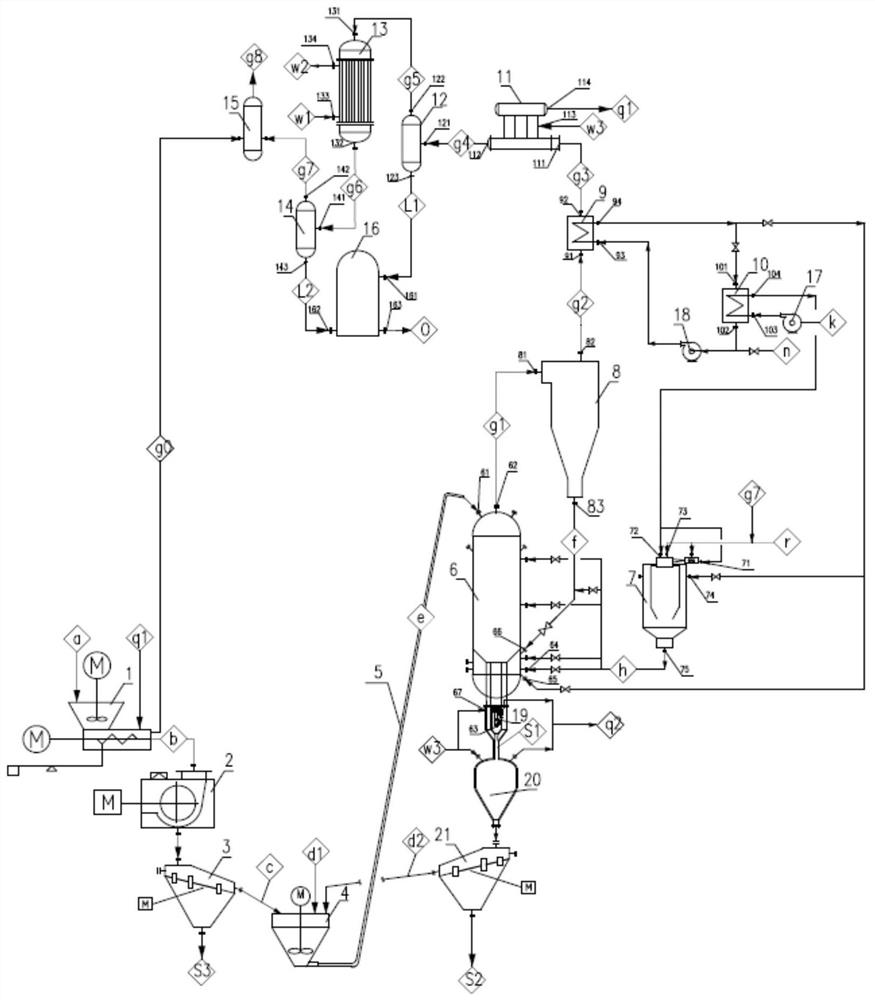

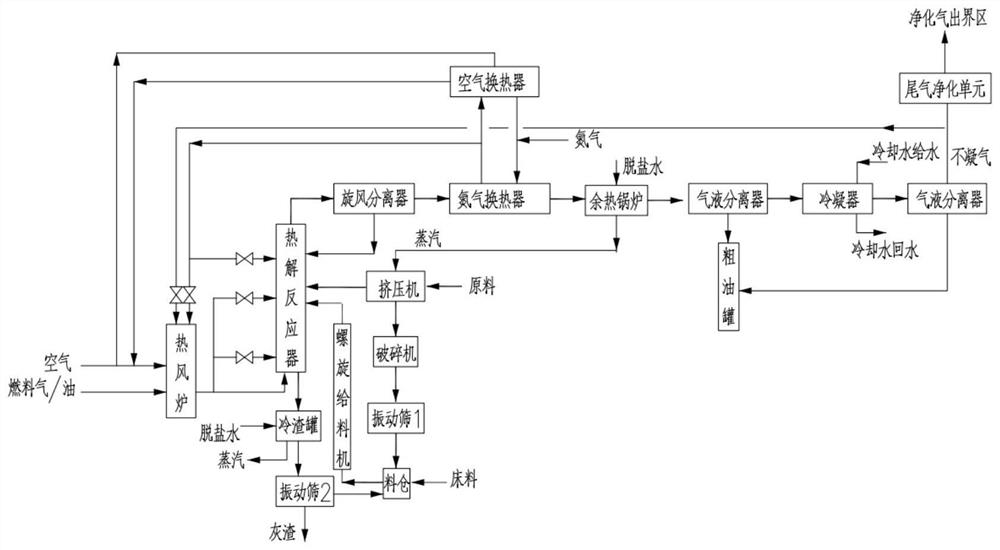

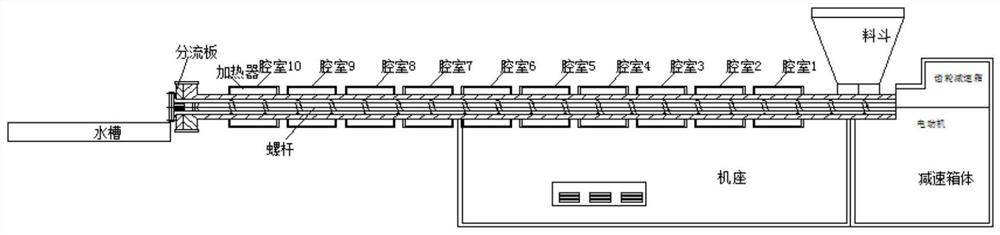

A technology for polymer polymerization and a process method, which is applied in the field of a polymer polymerization waste pyrolysis oil-making process method and a pyrolysis oil-making device field to achieve the effects of reducing feed blockage, improving heat transfer efficiency, and avoiding coking phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] 1. Raw materials: Waste plastics recovered from landfill waste through multi-stage sorting, mainly waste plastics with a small amount of soil, are crushed into irregular small pieces by a crusher. Waste plastics mainly come from packaging waste, automobile waste and processing waste. The percentages of various types of waste plastics are low-density polyethylene (LDPE), 27%; high-density polyethylene (HDPE), 21%, polypropylene (PP ), 18%; polystyrene (PS), 16%; polyvinyl chloride (PVC), 7%.

[0069] 2. Analysis of pyrolysis products: Use the above-mentioned polymer polymer waste pyrolysis oil production process and equipment to carry out pyrolysis oil production, collect crude oil and pyrolysis gas products (gas collection bag sampling), and use ethyl acetate to clean The condenser obtains the cleaning liquid, and then the cleaning liquid is subjected to centrifugal rotary evaporation, and finally the residual liquid of the rotary evaporation is dissolved in tetrahydrof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com