Polyimide resin, polyimide film and preparation method and application thereof

A technology of polyimide resin and polyimide film, which is applied in the field of polyimide film, can solve the problems of low water absorption and air isolation, high toughness of fluorine-containing monomers, and high water absorption of the film, so as to reduce water absorption Good moisture absorption, CTE and thermal stability, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

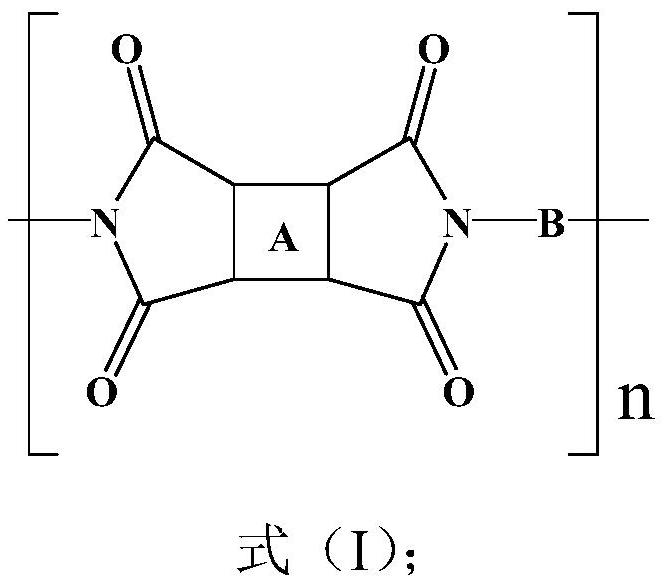

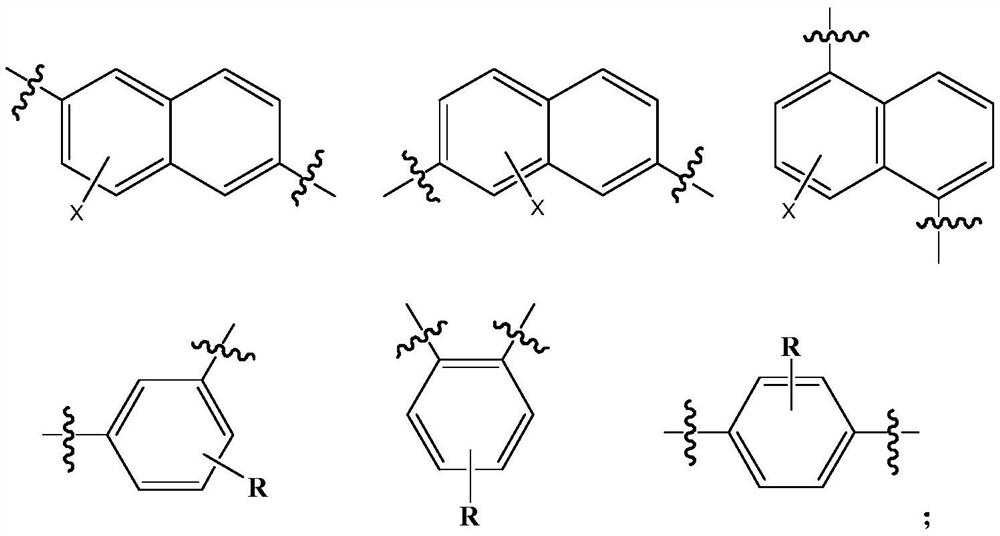

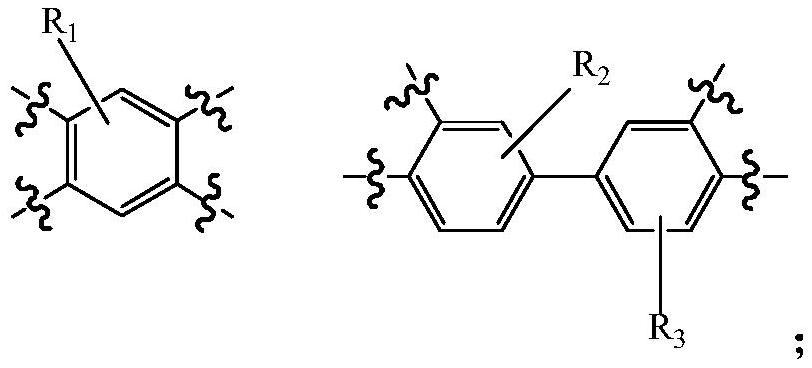

[0057] The structure of the polyimide film of the present embodiment is shown in (i):

[0058]

[0059] Among them, A is B is

[0060] The preparation method of the polyimide film of the present embodiment includes the steps of:

[0061] (1) Constructing a double-layer glass jacket reaction bottle, accessing the circulating water bath, the temperature is maintained at 30 ° C, under the protection of nitrogen, add 10.8658 g (0.086 mol) 2-fluoro-1,4-phenylenediamine By 205 g of N-methylpyrrolidone, stirring at 30 ° C for 20 min to completely dissolve, 25.3460 g (0.086 mol) 3, 3 ', 4,4'-biphenyl tetral carnamen (4,4'-biphenyl) dialhydride was added multiple times in the system. BPDA), the resin color is deepened, the viscosity is increased, and the temperature is maintained for 5 h, resulting in a polyimide resin solution having a solid content of 15%, and the final viscosity is 10203 cp;

[0062] (2) The polyimide resin solution is applied to a clean and flat glass plate, then p...

Embodiment 2

[0065] The structure of the polyimide film of the present embodiment is shown in (i):

[0066]

[0067] Among them, A is B is

[0068] The preparation method of the polyimide film of the present embodiment includes the steps of:

[0069] (1) Construct a double-layer glass jacket reaction bottle, access the circulating water bath, temperature maintained at 20 ° C, under the protection of nitrogen, 11.9062 g (0.0826 mol) 2,5-difluoro-1,4-phenyl Diamine was added to 205 g of N, N-dimethylformamide, stirred at 20 ° C for 20 min to completely dissolve, and 24.3056 g (0.0826 mol) 3, 3 ', 4, 4'- Benophenyl tetramethloride (BPDA), the resin color is deepened, the viscosity is increased, and the temperature is maintained for 5 h, resulting in a polyimide resin solution, the final viscosity is 9806 cp;

[0070] (2) The polyimide resin solution is applied to a clean and flat glass plate, then placed in a dry oven of a nitrogen atmosphere, thermimimine, temperature: 60 ° C / 1H, 200 ° C / ...

Embodiment 3

[0073] The structure of the polyimide film of the present embodiment is shown in (i):

[0074]

[0075] Among them, A is B is

[0076] The preparation method of the polyimide film of the present embodiment includes the steps of:

[0077] (1) Constructing a double-layer glass jacket reaction bottle, accessing the circulating water bath, the temperature is maintained at 60 ° C, under the protection of nitrogen, 1,3,5,6-tetrafluoro-1, 4 - phenylenediamine added to 205 g of N-ethylpyrrolidone, stirred at 60 ° C for 20 min to completely dissolve, 22.4618 g (0.0763 mol) 3, 3 ', 4, 4'- Benophenyl tetramethloride diallorhydride (BPDA), the resin color derived, the viscosity increased, and the temperature was maintained for 5 h, resulting in a polyimide resin solution, and finally viscosity of 9557 cp;

[0078] (2) The polyimide resin solution is applied to a clean and flat glass plate, then placed in a dry oven of a nitrogen atmosphere, thermimimine, temperature: 60 ° C / 1H, 200 ° C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com