A kind of nano iron oxyhydroxide gel composite material and its preparation method and application

A technology of iron oxyhydroxide and composite materials, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as easy agglomeration and difficulty in recycling, so as to reduce environmental pollution and save costs , the effect of strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Weigh 3.00g of acrylamide (AM), 5.00g of alkaline pulping and papermaking black liquor (from Guangzhou Paper Group Co., Ltd., containing alkali lignin LS), 1.00g of maleic anhydride (MAH), Combined agent N,N-methylenebisacrylamide (NMBA) 0.01g, add 20mL deionized water, stir mechanically until all raw materials are completely dissolved, mix evenly, and then mix 0.1mol·L - 1 FeSO 4 .7H 2 O solution 10mL.

[0052] (2) Add 0.05 g of initiator potassium persulfate (KPS) to the mixture after uniform stirring for 1 h in step (1), stir evenly, after fully dissolving, let it stand until a gel is formed, wash thoroughly, and then freeze-dry for 6 h ;

[0053] (3) Soak the xerogel obtained in step (2) in 1mol L -1 NaHCO 3 solution for 2 hours, and then dried in the air (or dried with oxygen) to obtain the nano-iron oxyhydroxide gel composite material.

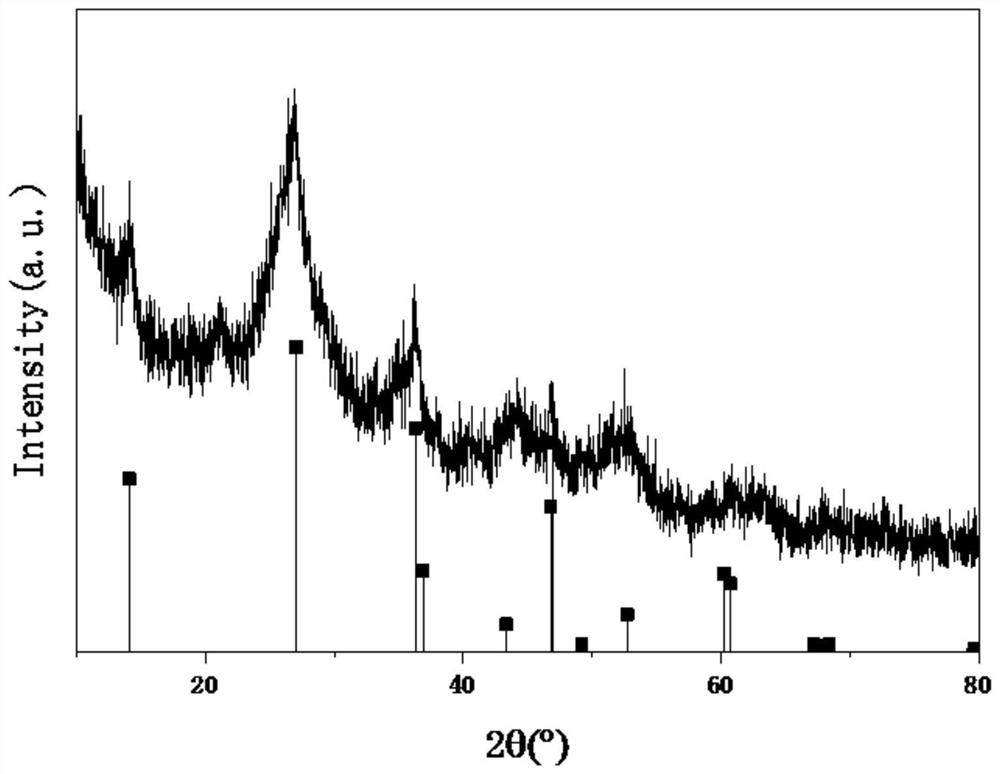

[0054] The appearance of the nanometer iron oxyhydroxide gel composite material is as follows figure 1 shown.

[00...

Embodiment 2

[0058] (1) Weigh 4.00g of acrylamide (AM), 5.00g of alkaline pulping and papermaking black liquor (from Guangzhou Paper Group Co., Ltd.), 1.00g of maleic anhydride (MAH), crosslinking agent N,N- Add 0.01g of methylenebisacrylamide (NMBA), add 20mL of deionized water, stir mechanically until all raw materials are completely dissolved, mix evenly, and then mix 0.1mol·L -1 FeSO 4 .7H 2 O solution 10mL.

[0059] (2) Add 0.05 g of initiator potassium persulfate (KPS) to the mixture after uniform stirring for 2 hours in step (1), stir evenly, after fully dissolving, let it stand until a gel is formed, wash thoroughly, and then freeze-dry for 12 hours ;

[0060] (3) Soak the xerogel obtained in step (2) in 1mol L -1 NaHCO 3 The solution is dried for 4 hours, and then dried in the air (or dried with oxygen) to obtain the nano-iron oxyhydroxide gel composite material.

Embodiment 3

[0062] (1) Weigh 5.00g of acrylamide (AM), 5.00g of alkaline pulping and papermaking black liquor (from Guangzhou Paper Group Co., Ltd.), 1.00g of maleic anhydride (MAH), crosslinking agent N,N- Add 0.01g of methylenebisacrylamide (NMBA), add 20mL of deionized water, stir mechanically until all raw materials are completely dissolved, mix evenly, and then mix 0.1mol·L -1 FeSO 4 .7H 2 O solution 10mL.

[0063] (2) Add 0.05 g of initiator potassium persulfate (KPS) to the mixture after uniform stirring for 1 h in step (1), stir evenly, after fully dissolving, let it stand until a gel is formed, wash thoroughly, and then freeze-dry for 18 h ;

[0064] (3) Soak the xerogel obtained in step (2) in 1mol L -1 NaHCO 3 solution for 3 hours, and then dried in the air (or dried with oxygen) to obtain the nano-iron oxyhydroxide gel composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com