Glass powder suitable for OLED packaging as well as preparation method and application thereof

A basic glass powder and glass filler technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of high price, toxicity, sealing failure, etc., and achieves the inhibition of devitrification and the simple preparation process. , Inhibit the effect of adjusting the thermal expansion coefficient of glass by an appropriate amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

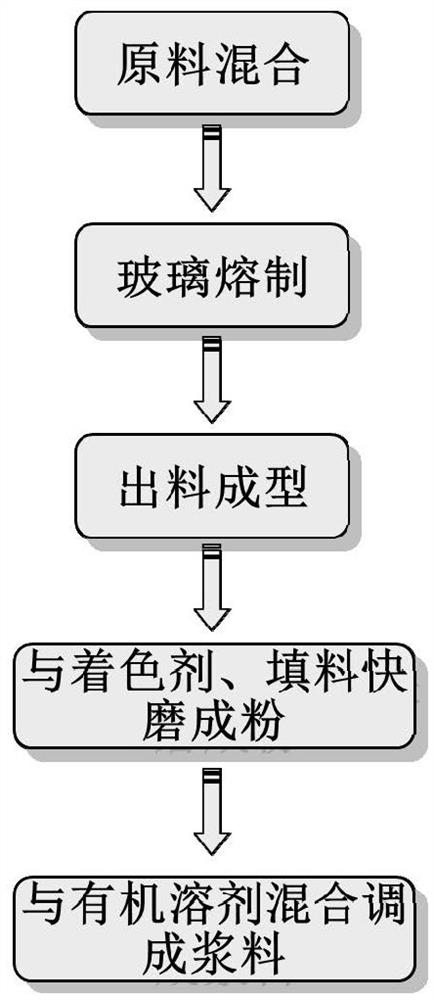

[0077] (1) According to the glass ratio of Example 1 in Table 1, with the total mass as 1000g, calculate and take each corresponding raw material: Bi 2 o 3 627.18g, H 3 BO 3 210.33g, ZnO 90.44g, Na 2 CO 3 24.91g, Nd 2 o 3 13.58g, MgO 15.37g, BaCO 3 18.17g, add the prepared material to 2000g deionized water and planetary ball mill for 1 hour, the mass ratio of material: grinding ball is 4:1, discharge the material, and dry it in a constant temperature drying oven at 150°C for 12 hours to obtain the mixture;

[0078] (2) Put the mixture obtained in step (1) in an alumina crucible, raise the temperature to 1000°C at 3°C / min and keep it warm for 1.5 hours, and then quench the molten glass obtained by melting to obtain glass shards;

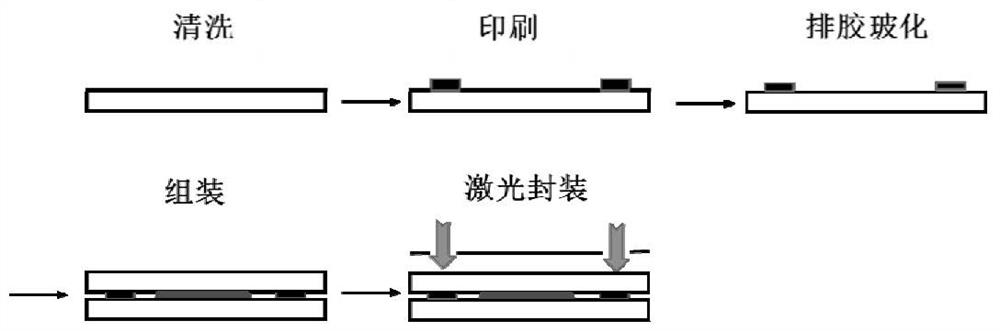

[0079] (3) Using Fe 3 o 4 、Co 2 o 3 The calcined material obtained after mixing according to the molar ratio of 1:1 and keeping it warm at 1000°C for 4 hours was used as a colorant. The filler uses self-made quartz glass powder with a p...

Embodiment 2

[0086] The difference with Example 1 is: take the total mass as 1000g, calculate and take each corresponding raw material: Bi 2 o 3 696.68g, H 3 BO 3 170.53g, ZnO 81.57g, Na 2 CO 3 14.15g, Sb 2 o 3 10.76g, MgO 7.45g, Al 2 o 3 18.85g. The same method as in Example 1 was used to package the OLED element.

Embodiment 3

[0088] The difference with Example 1 is: take the total mass as 1000g, calculate and take each corresponding raw material: Bi 2 o 3 652.38g, H 3 BO 3 229.21g, ZnO 71.13g, Na 2 CO 3 12.89g, SrCO 3 25.52g, Sb 2 o 3 8.87g. The same method as in Example 1 was used to package the OLED element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com