High-precision milling machining method for hob of hard alloy granulator

A milling process, hard alloy technology, applied in the direction of metal processing equipment, grinding workpiece support, milling cutter, etc., can solve the problems of affecting milling efficiency, hob time-consuming and labor-intensive, etc., to improve cutting accuracy, improve milling efficiency, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

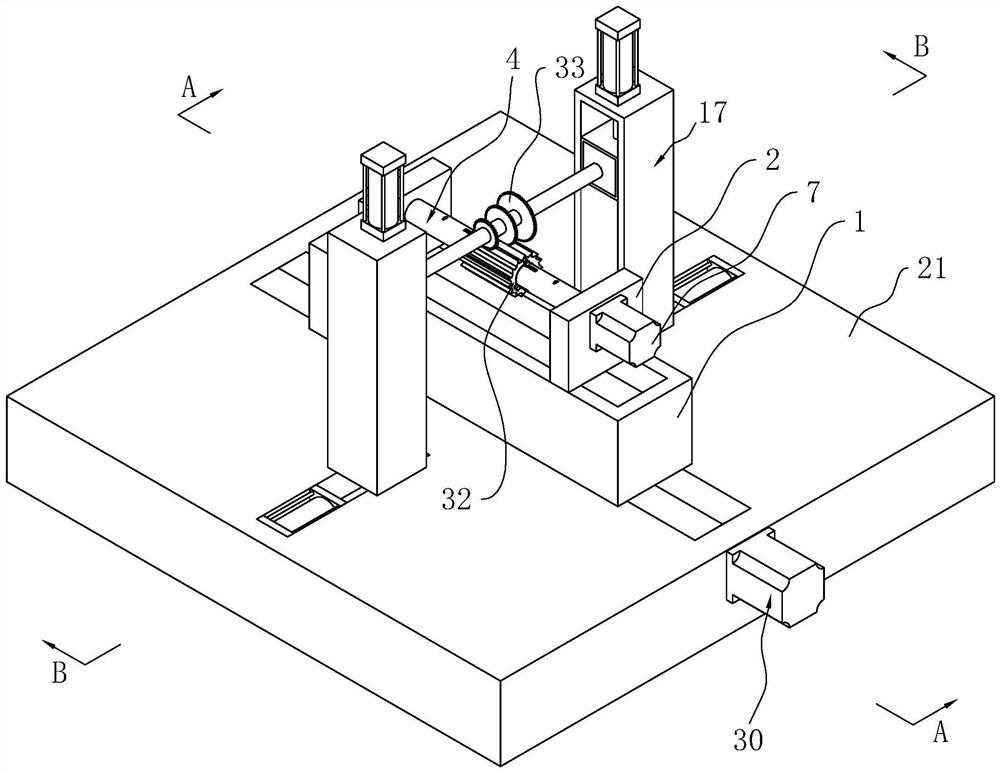

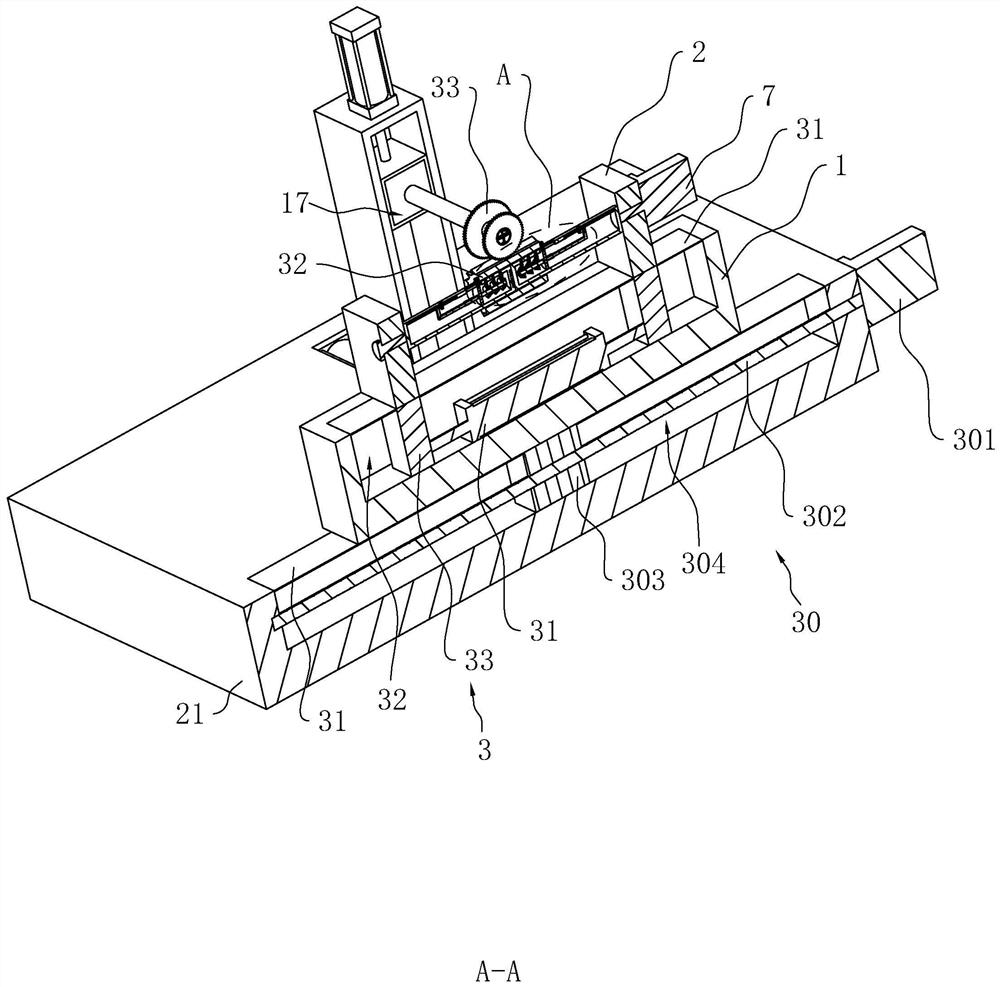

[0047] The following is attached Figure 1-9 The application is described in further detail.

[0048] The embodiment of the present application discloses a high-precision milling method for a hard alloy granulator hob. refer to figure 1 with figure 2 , the high-precision milling method of the carbide granulator hob includes the following steps:

[0049] Step S1: Firstly, according to the size specification of the hob 32 to be processed, install the grinder 33 of the corresponding size specification on the milling table 1;

[0050] Step S2: two positioning plates 2 are installed on the milling table 1, and locking mechanisms 4 for fixing the hob 32 are installed on the opposite side walls of the two positioning plates 2, and a locking mechanism 4 for fixing the hob 32 is installed on the milling table 1 for adjusting the two positioning plates. A distance adjusting mechanism 3 for the distance between the positioning plates 2;

[0051] Step S3: first use the distance adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com