Treatment and application method of nut waste

An application method and waste technology, applied in the field of nut waste treatment and application, can solve the problems of low calorific value, unstable chemical properties and high cost of bio-oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

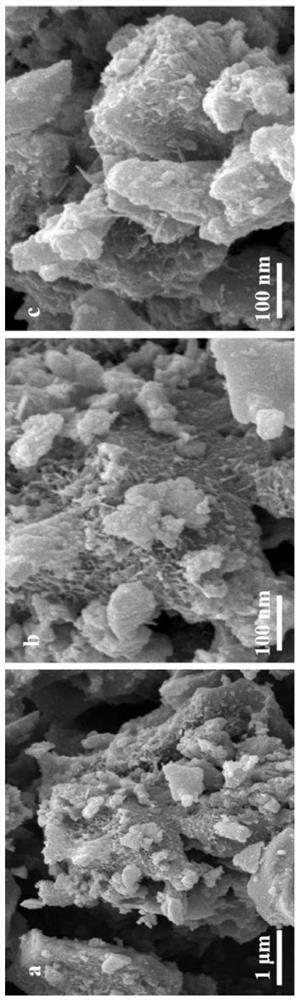

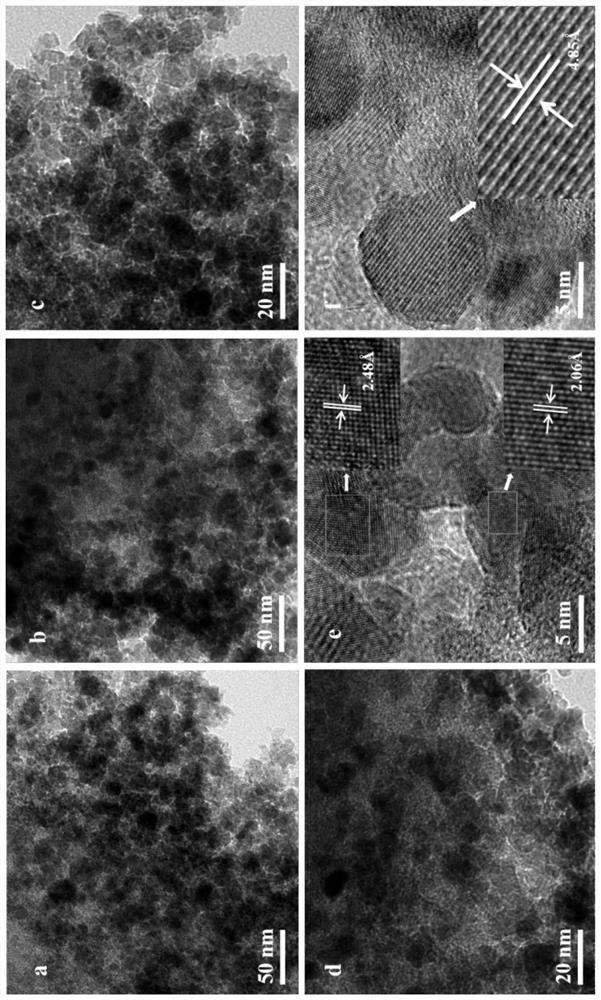

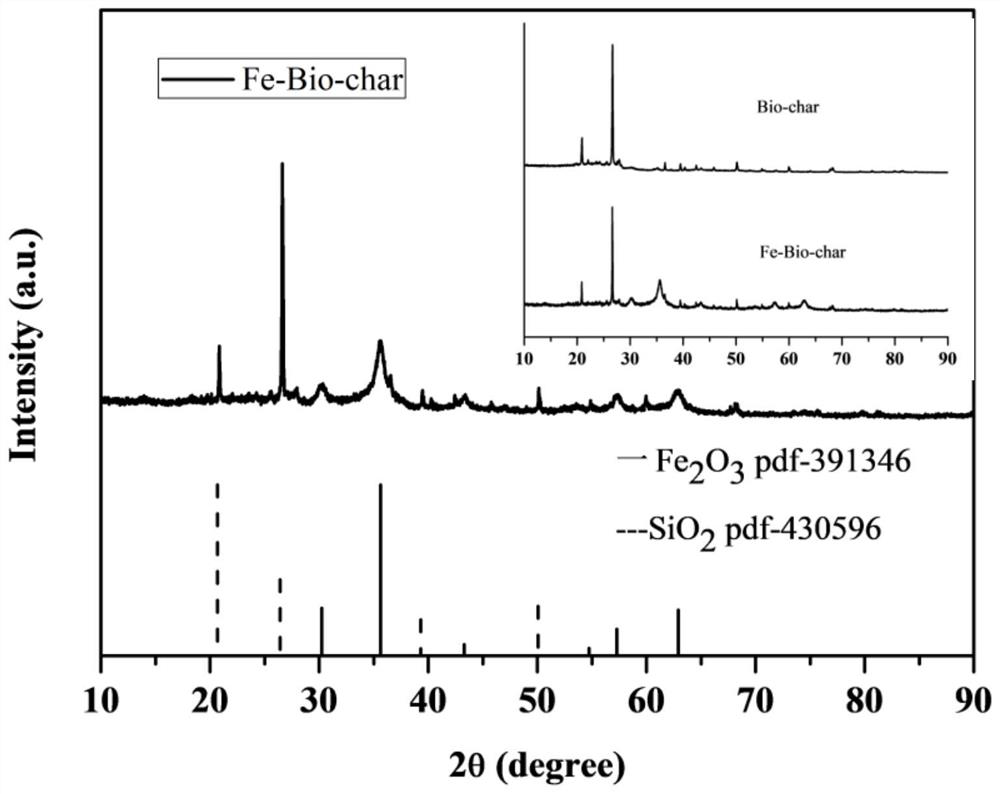

[0036]Nitrogen gas was passed into the microwave pyrolysis furnace at a flow rate of 50ml / min for 15 minutes, and then under the conditions of microwave power of 750W and pyrolysis reaction temperature of 550°C, microwave pyrolysis of nut waste peanut shells was carried out for 15 minutes. The solid product biochar after pyrolysis was collected and put into a ball mill for 1 h at 500 r / min. Prepare 0.1mol / L hydrochloric acid: take 3.5ml of concentrated hydrochloric acid with a mass fraction of 36wt%-38wt% and mix it with 400ml deionized water, then mix the polished peanut shell biochar with the prepared hydrochloric acid solution on a magnetic stirrer Stirring was continued for 6h. Then carry out suction filtration, wash and put in the oven of 90 ℃ to carry out overnight drying. The metal salt solution configuration method is as follows: respectively weigh ferrous chloride tetrahydrate and anhydrous ferric chloride with a molar ratio of 1:2 and dissolve them in deionized wate...

Embodiment example 2

[0044] In order to quickly verify the performance of Fe-modified biochar catalysts, the pyrolysis products were analyzed by fast pyrolysis-gas chromatography-mass spectrometry (Py-GC / MS). Use an electronic balance with an accuracy of 0.1 mg to weigh a small amount of peanut shell material powder and put it into a small pyrolysis crucible, then weigh the Fe-modified biochar catalyst that is 20% of the mass of the peanut shell material and place it on the peanut shell powder. The total amount should not exceed half of the small crucible, and finally take a small ball of quartz wool to cover the material to prevent the powdery material from rushing out during rapid pyrolysis. The pyrolysis temperature was set at 550 °C and the residence time was 18 s. The interface temperature was maintained at 250°C, helium was used as the mobile phase to maintain vacuum at a flow rate of 0.5-1ml / min, and the split ratio was 1:25. A DB-5 capillary column (30 m x 0.25 mm x 0.25 μm) was used for ...

Embodiment example 3

[0047] In order to verify the effect of Fe-modified biochar catalyst on the selectivity of bio-oil components obtained by microwave pyrolysis of peanut shells, catalytic pyrolysis experiments were carried out using a combined catalytic fixed-bed reactor and microwave pyrolysis reactor. The raw material selects peanut shells, weighs a certain amount of peanut shells and activated carbon (microwave absorber) on an electronic balance and places them in a 500ml quartz flask, then places the quartz flask in a microwave pyrolysis device, and places 20% of it in a fixed bed reactor. Fe modified biochar catalyst, catalytic fixed bed reaction temperature is set to 550 °C. In order to verify the effect of Fe-modified biochar catalyst on the selectivity of bio-oil components obtained by microwave pyrolysis of peanut shells, two sets of comparative experiments were set up, one without catalyst and one with catalyst. The temperature of the microwave pyrolysis reactor was set at 550°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com