Coordinated control method and system driven by multiple sets of equipment or units sharing one power source

A coordinated control system and coordinated control technology, applied in the field of control, can solve the problems of increasing equipment investment, wasting energy, and increasing the number of electrical equipment, and achieve the effects of reducing maintenance workload, reducing investment, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

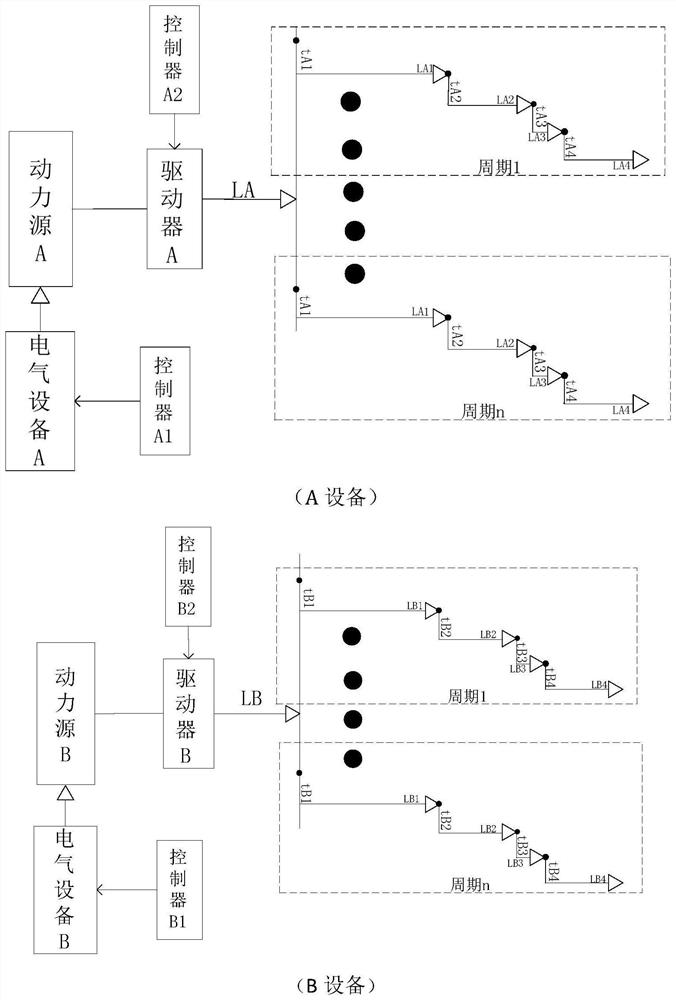

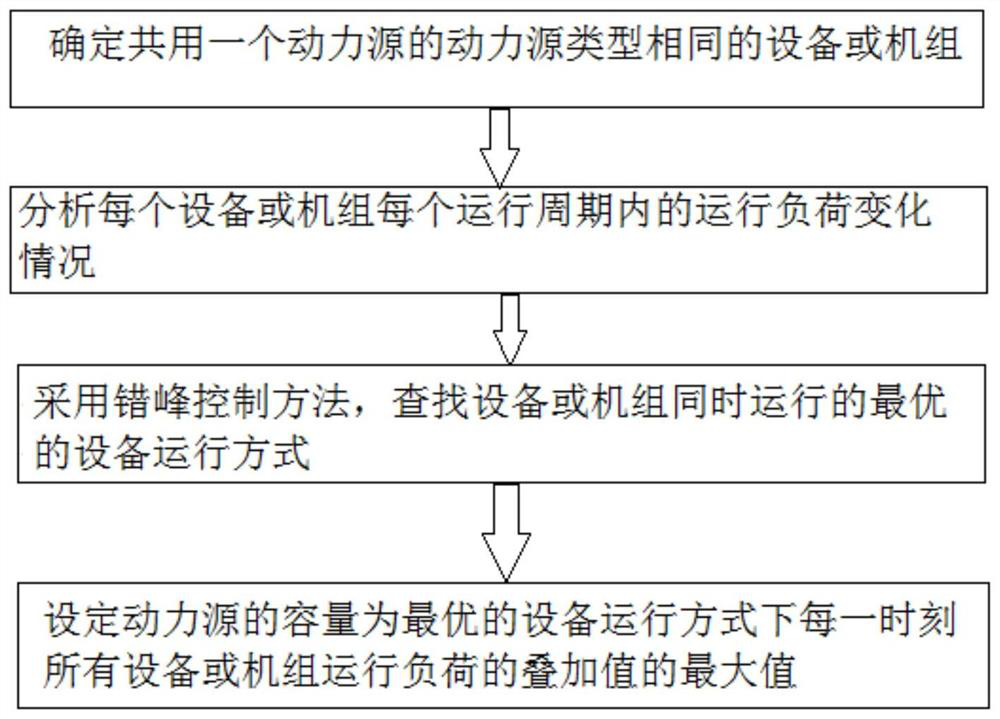

Method used

Image

Examples

Embodiment 2

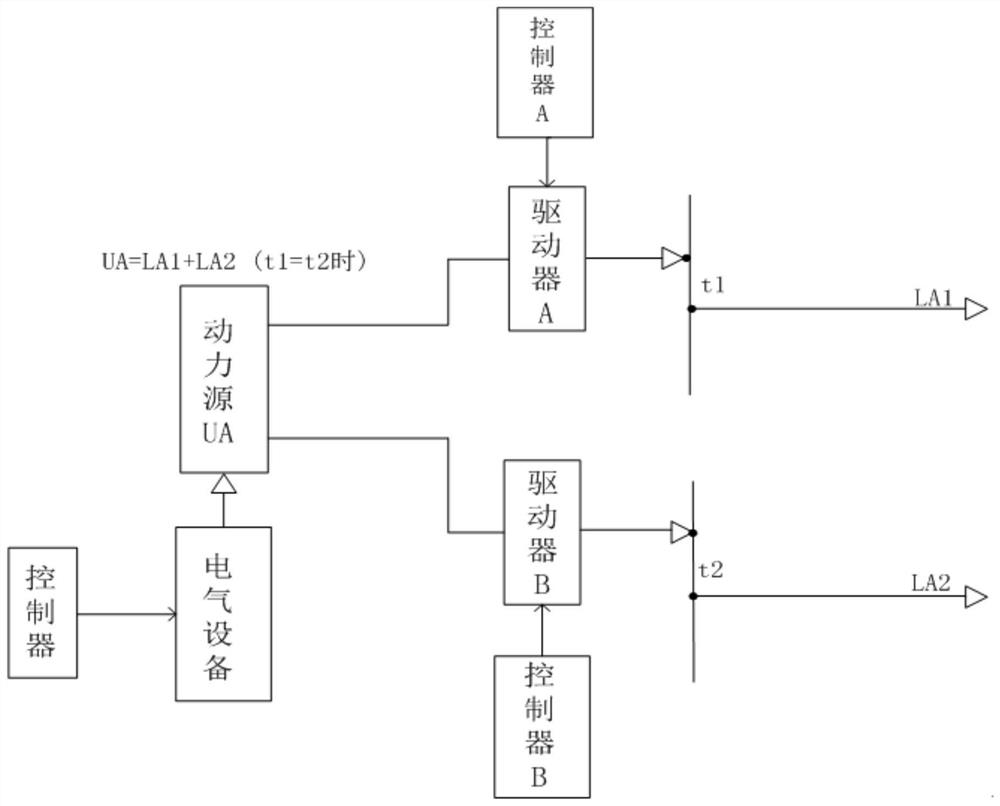

[0047] This embodiment is used to illustrate the control method of the present invention when more than two sets of equipment or units share one power source.

[0048] The specific control method is: control each equipment or unit to be put into operation at different times, so that the maximum operating load of each equipment or unit does not overlap; or, according to the size of the operating load of the equipment or unit operating cycle, select the At the moment when the above-mentioned equipment or unit is put into operation, within the operation period of the equipment or unit with the longest operation period of the equipment or unit, the maximum value of the superimposed value of the operating load of all equipment or units at each moment is the smallest .

[0049] When the same equipment or units share the same power source and operate the same process:

[0050] Same as the control method as shown in Figure 3, and the same as the numerical setting of the load in embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com