Preparation method of high-strength corrosion-resistant industrial filter cloth

A corrosion-resistant, high-strength technology, applied in the field of preparation of high-strength corrosion-resistant industrial filter cloth, can solve the problems of filter cloth material uncertainty, complexity, and reduced filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A high-strength corrosion-resistant industrial filter cloth, which includes the following steps:

[0038] Step S1: PET polyester slice, enhanced particles, corrosion resistant particles, plasticizer to the extruder, melt extruded, prepared polyester fibers;

[0039] Step S2: Wove the polyester fiber into the fabric to make a high strength corrosion resistant industrial filter cloth.

[0040] The enhanced particles are made of steps:

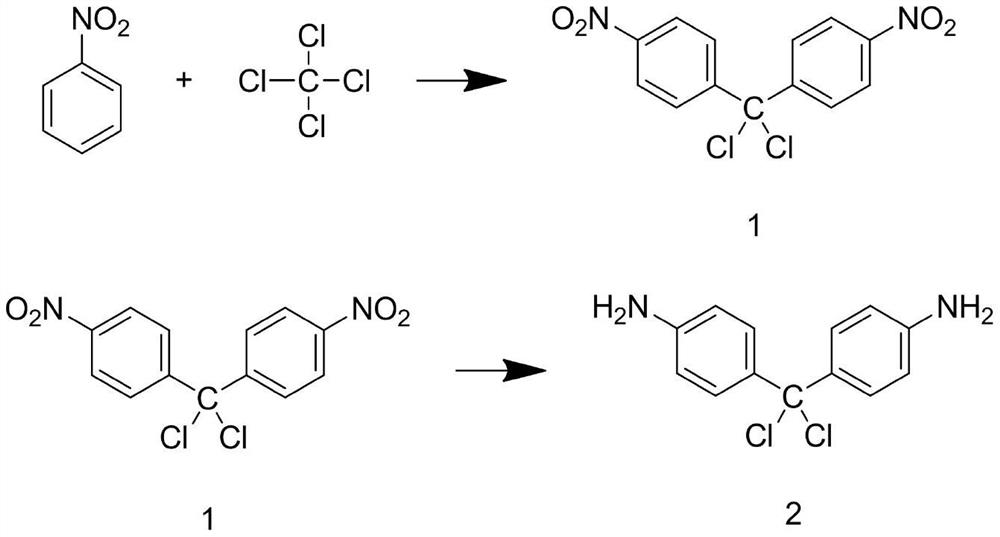

[0041] Step A1: Add trichloride and carbon tetrachloride to the reaction kettle, at a temperature of 150 r / min, the temperature is 10 ° C, stirring and added nitrobenzene, reacting at a temperature of 40 ° C. 1H, the intermediate body 1 is obtained, and the intermediate 1, iron powder, ethanol is added to the reactor, and after reflowing at a temperature of 80 ° C, the hydrochloric acid solution is added, and the solution is 20 min, and the reaction is continued for 5 hours. The reaction liquid pH is 7, and the intermediate 2 is produced, an...

Embodiment 2

[0049] A high-strength corrosion-resistant industrial filter cloth, which includes the following steps:

[0050] Step S1: PET polyester slice, enhanced particles, corrosion resistant particles, plasticizer to the extruder, melt extruded, prepared polyester fibers;

[0051] Step S2: Wove the polyester fiber into the fabric to make a high strength corrosion resistant industrial filter cloth.

[0052] The enhanced particles are made of steps:

[0053] Step A1: Add trichloride and carbon tetrachloride to the reaction kettle, and stirred and nitrobenzene under conditions of 150 r / min, the temperature is 15 ° C, and the nitrobenzene is added, and the reaction is at a temperature of 40 ° C. 1.5H, the intermediate 1 is obtained, and the intermediate 1, iron powder, ethanol is added to the reactor, and after the temperature is 80 ° C, the reaction is refluxed for 5 h, the hydrochloric acid solution is added, and the time 20 min is added, and the reaction is continued for 5 h. The reactio...

Embodiment 3

[0061] A high-strength corrosion-resistant industrial filter cloth, which includes the following steps:

[0062] Step S1: PET polyester slice, enhanced particles, corrosion resistant particles, plasticizer to the extruder, melt extruded, prepared polyester fibers;

[0063] Step S2: Wove the polyester fiber into the fabric to make a high strength corrosion resistant industrial filter cloth.

[0064] The enhanced particles are made of steps:

[0065] Step A1: Add trichloride and carbon tetrachloride to the reaction kettle, and stirred and nitrobenzene is stirred and added to the condition of 15 ° C, and the temperature is at a temperature of 45 ° C, the reaction is reacted. 1.5H, the intermediate 1 is obtained, and the intermediate 1, iron powder, ethanol is added to the reactor, and after reflow reaction at a temperature of 85 ° C, the hydrochloric acid solution is added, and the time 20 min is added, and the reaction is continued for 8h, The reaction liquid pH is 8, and the interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com