Molten salt corrosion resistant coating containing nickel-tantalum active diffusion barrier layer and preparation method

A corrosion-resistant coating and molten salt-resistant technology, applied in the coating, superimposed layer plating, metal material coating process, etc. Poor performance and other problems, to avoid the deterioration of the mechanical properties of the matrix, the effect is small, and the interface bonding strength is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The substrate is made of GH3535 alloy, and the substrate sample is 20×10×4mm. The nickel-tantalum coating is prepared by magnetron sputtering double-target sputtering. The purity of both nickel and tantalum targets is 99.99 wt.%. After cleaning the surface of the matrix sample, put it into the working room, hang the sample between two parallel targets, and vacuum the working room to 7×10 -3 ~1×10 -2 . Heat the substrate sample to 200°C, start sputtering, sputtering power: 2000W for Ni target, 1000W for Ta target; time 1h, nickel-tantalum layer thickness is about 2μm. In this embodiment, the chemical composition and content of the nickel-tantalum inner layer are as follows: the nickel content is about 72.2 wt.%, and the rest is tantalum element.

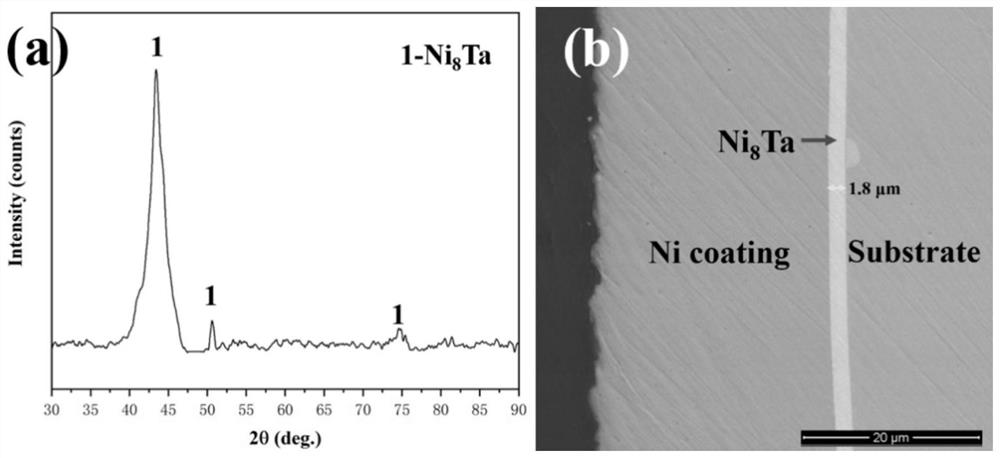

[0033] The phase analysis of the deposited nickel-tantalum film was carried out, and the X-ray diffraction analysis showed that the prepared nickel-tantalum layer was Ni 8 Ta phase, the result is as follows figure 1 (a) sh...

Embodiment 2

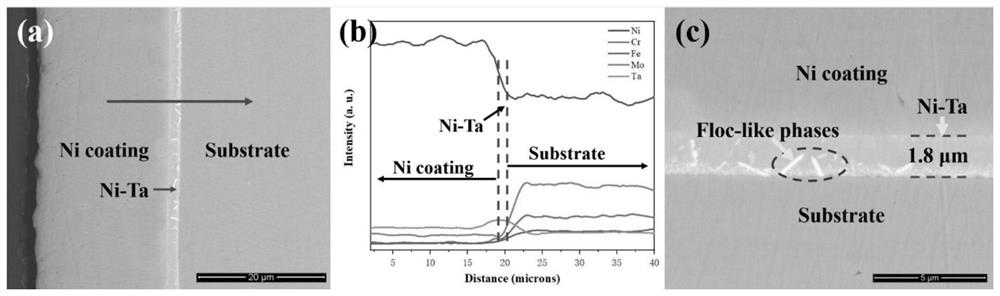

[0039] The base material is Inconel-617 alloy, the base sample is 20×10×4mm, and the nickel-tantalum coating is prepared by magnetron sputtering double-target sputtering. The purity of both nickel and tantalum targets is 99.99 wt.%. After cleaning the surface of the matrix sample, put it into the working room, hang the sample between two parallel targets, and vacuum the working room to 7×10 -3 ~1×10 -2. Heat the substrate sample to 200°C and start sputtering for 2 hours, the thickness of the nickel-tantalum layer is about 4 μm, the sputtering power of the nickel target is 2000W, and the tantalum target is 2600W. In this embodiment, the chemical composition and content of the nickel-tantalum inner layer are as follows: the nickel content is about 50.0 wt.%, and the rest is tantalum element. Then, a pure Ni coating with a thickness greater than 40 μm was prepared on the surface of the sample by sulfamate nickel plating. After the samples were heat treated at 700℃-100h, it wa...

Embodiment 3

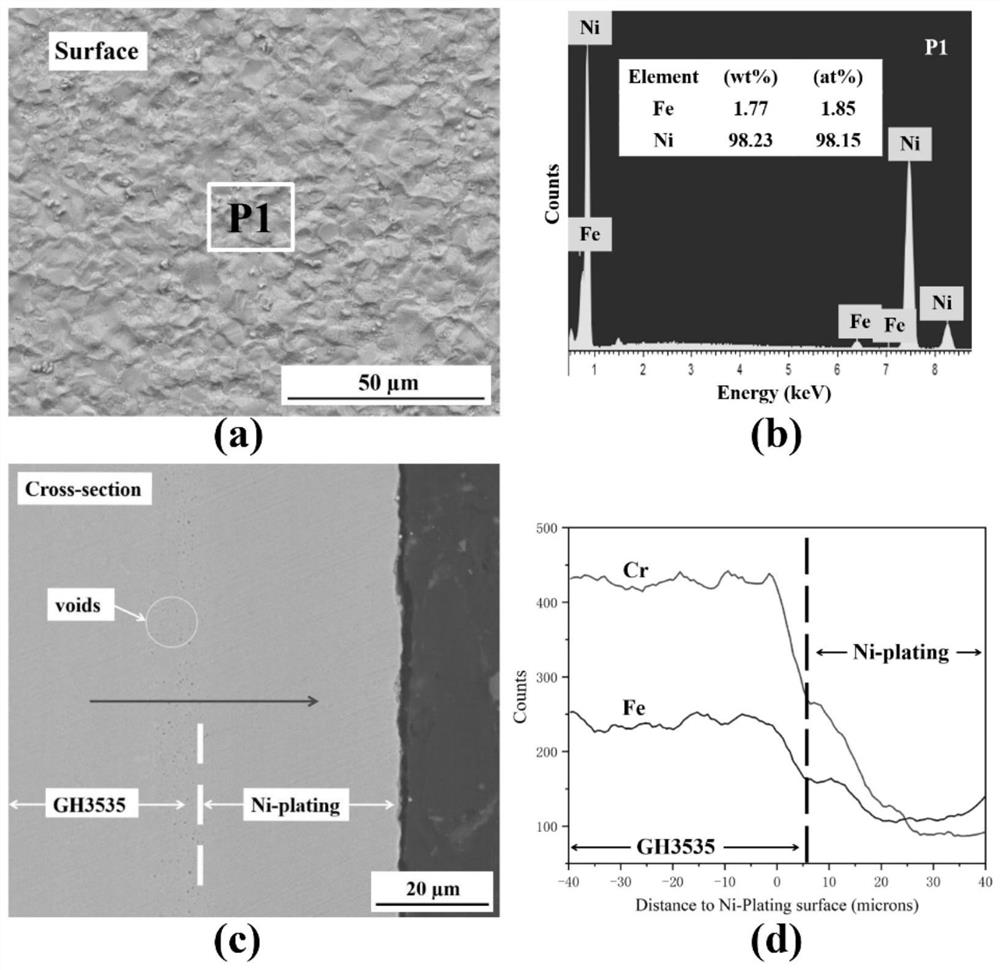

[0041] The iron-based Incoloy-800H alloy was used as the substrate, and the substrate sample was 10×10×4mm. The nickel-tantalum coating was prepared by magnetron sputtering. Among them, the purity of the nickel and tantalum targets are both 99.99wt.%. The substrate sample is cleaned and loaded into the working room, the sample is suspended between two parallel targets, and the working room is vacuumed to 7×10 -3 ~1×10 -2 . Heat the substrate sample to 200°C and start sputtering for 2 hours, the thickness of the nickel-tantalum layer is about 4 μm, the sputtering power of the nickel target is 2000W, and the tantalum target is 5600W. In this embodiment, the chemical composition and content of the nickel-tantalum inner layer are as follows: the nickel content is about 31.0 wt.%, and the rest is tantalum element. Then, a pure Ni coating with a thickness greater than 40 μm was prepared on the surface of the sample by sulfamate nickel plating. After the samples were heat treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com