Nail-like-graphite-free nodular cast iron for wind power equipment and preparation method thereof

A technology for wind power equipment and ductile iron, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of poor local mechanical properties of castings, deterioration of body elongation, economic loss of the whole machine, etc., and achieve excellent mechanical properties. performance, increase the nucleation capacity of graphite, and improve the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

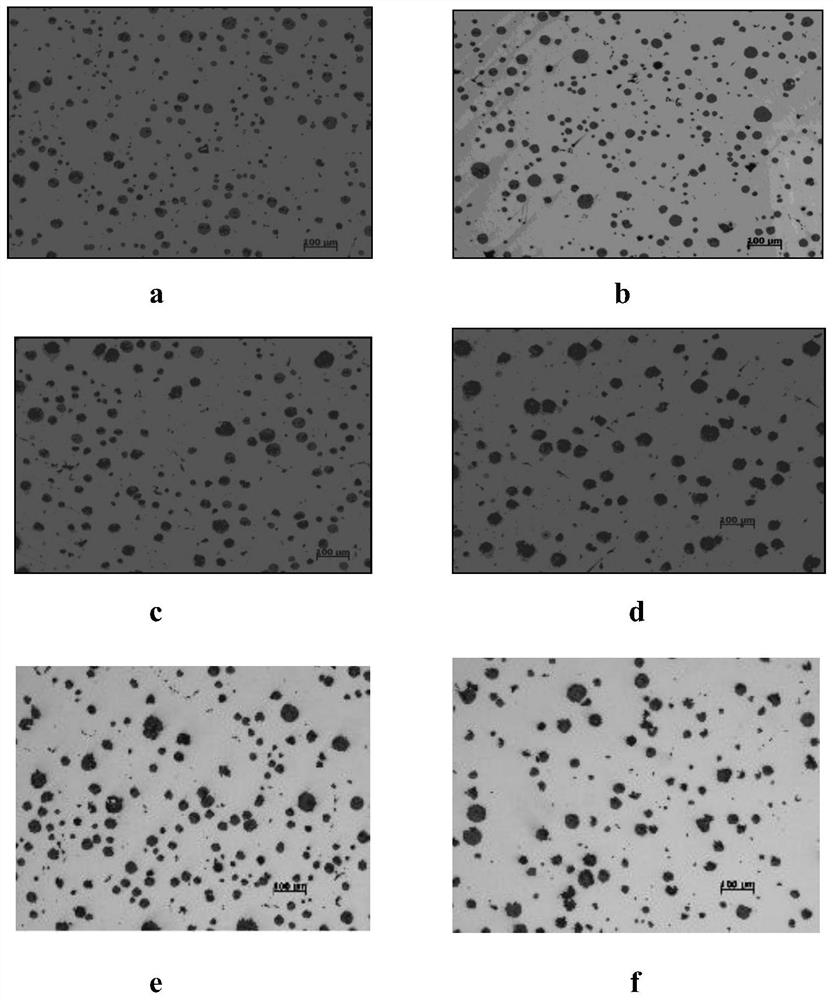

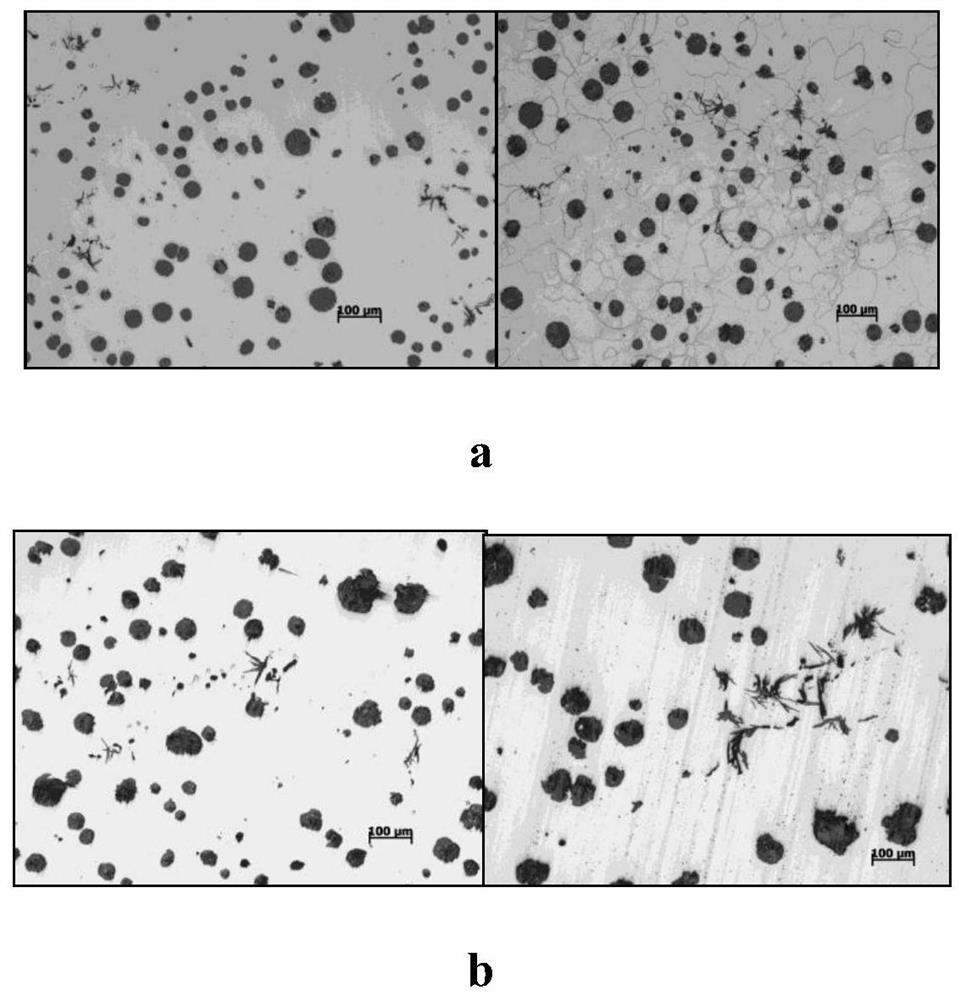

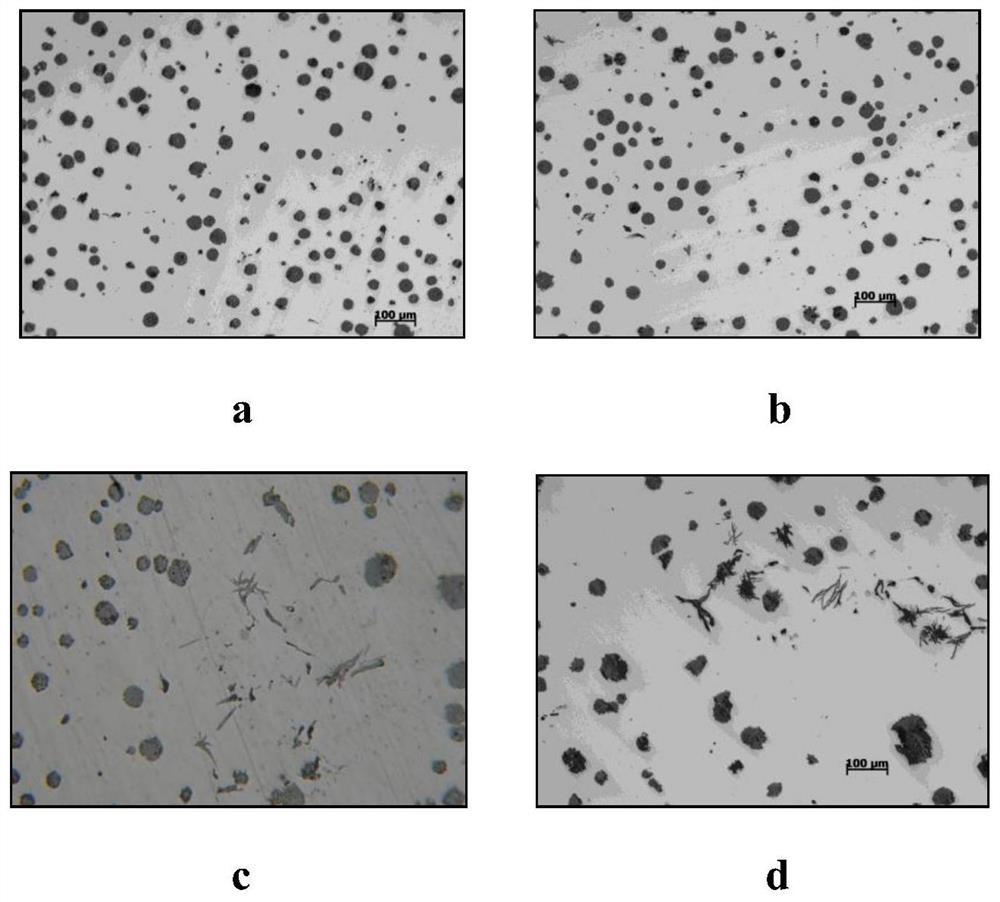

Image

Examples

Embodiment 1

[0042] S1. Furnace material selection: 60 parts of high-purity pig iron, 20 parts of high-quality steel scrap, 20 parts of returned furnace charge, 1 part of recarburizer, and 2 parts of ferrosilicon;

[0043] The composition and mass percentage of high-purity pig iron are: C≥2.5%, Si: <0.50%, Mn≤0.010%, P≤0.010%, Cr≤0.010%, Cu≤0.008%, Ti≤0.005%; V≤0.005 %, Mo≤0.0001%, Pb≤0.0009%, B≤0.0009%, Sn≤0.0009%, Bi≤0.0008%, and the balance is Fe.

[0044] The high-quality steel scrap composition and its mass percentage content are: C≤0.3wt%, Mn≤0.30wt%, Cr≤0.040wt%, S≤0.03wt%, and the balance is Fe.

[0045] Carburizer: sulfur content≤0.03wt%, nitrogen content≤0.010wt%.

[0046] The ferrosilicon composition and its mass percentage content are: Si 72-80wt%, Al≤1.20wt%, Mn≤0.50wt%, Cr≤0.50wt%, and the balance is Fe.

[0047] S2. Smelting: put high-purity pig iron, high-quality steel scrap, recycled material, recarburizer, and ferrosilicon in a smelting furnace for smelting, and control...

Embodiment 2

[0054] The difference from Example 1 is that the pouring temperature is: when the wall thickness of the mold is 25mm and 50mm, the pouring temperature is 1430°C; when the wall thickness of the mold is 95mm, the pouring temperature is 1425°C; When the thickness is 150mm, the pouring temperature is 1420°C; when the mold wall thickness is 400mm, the pouring temperature is 1415°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com