High-heat-conductivity high-molecular polymer composite heat-conducting material and preparation method thereof

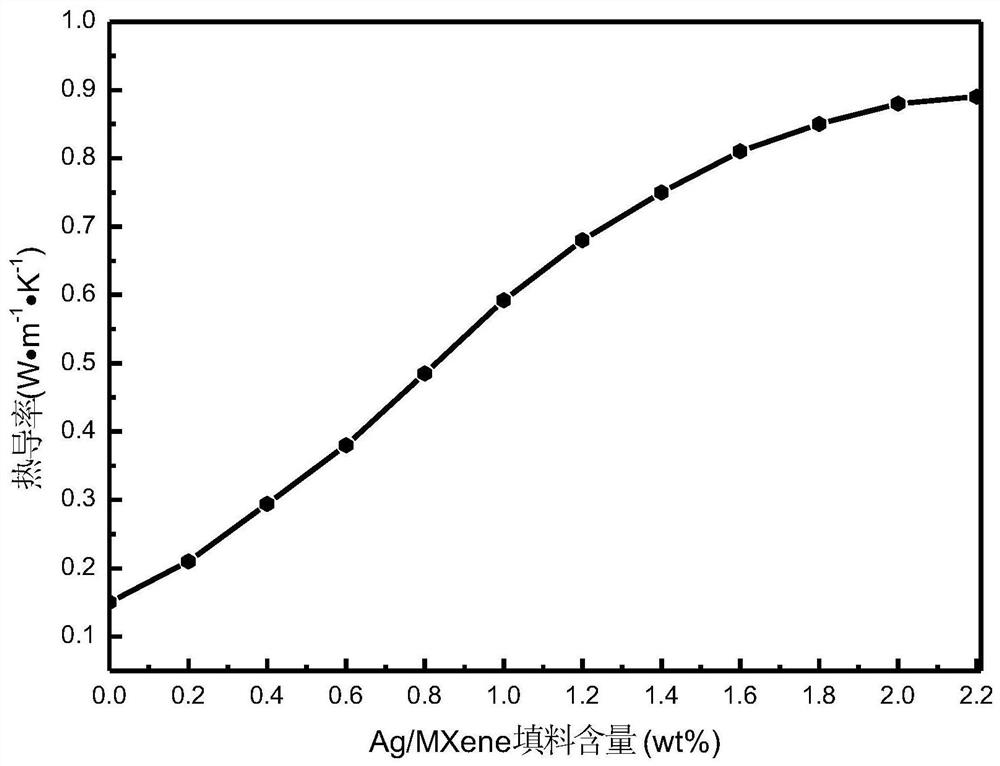

A technology of high molecular polymer and composite thermal conductive material, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problem of unsatisfactory thermal conductivity of MXene, achieve simple operation, excellent thermal conductivity, easy Evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

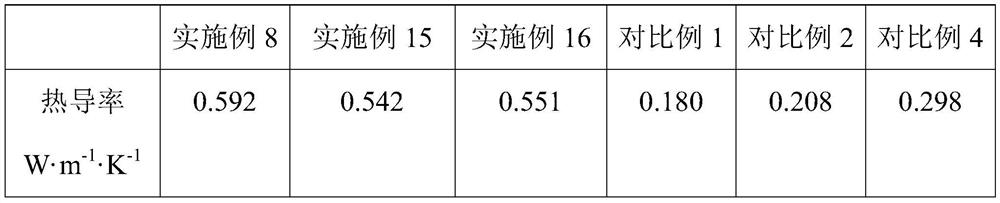

Examples

Embodiment 1

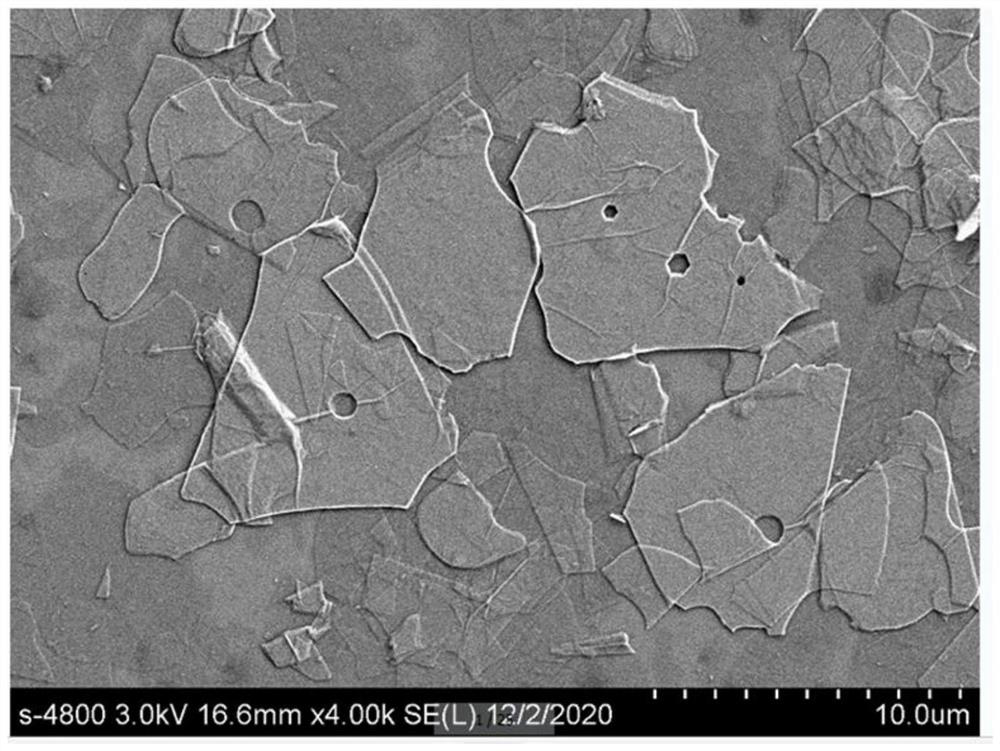

[0030] Preparation of a Ag / MXene Flake Composite

[0031] S1. Weigh a certain amount of Ti 3 AlC 2 (MAX) powder, slowly added to a polytetrafluoroethylene beaker filled with 50ml HF solution with a mass fraction of 40%, heated and stirred in a water bath at 60°C for 24 hours, and centrifuged with deionized water after the etching was completed. Wash until the pH of the solution is 6, and dry the centrifuged powder at 60°C for 24 hours in vacuum to obtain multilayer Ti 3 C 2 T x (MXene) powder;

[0032] S2, take 2g multi-layer Ti 3 C 2 T xThe powder was added to 30ml dimethyl sulfoxide (DMSO) solution, stirred at room temperature for 24 hours, then repeatedly centrifuged and washed with deionized water and ethanol to remove the DMSO solvent, and a sticky precipitate was obtained, which was dispersed in deoxidized deionized water. Protected with flowing argon, ultrasonically dispersed in an ultrasonic cleaner, and the suspension after ultrasonic filtration was suction-fi...

Embodiment 2

[0035] Preparation of a Ag / MXene Flake Composite

[0036] Compared with Example 1, the difference is only that S3 is different, and the rest are the same, specifically: S3, taking a certain amount of AgNO 3 Dissolved in 50ml deionized water to prepare AgNO 3 solution, 1g Ti 3 C 2 T x The flakes were slowly added to the above AgNO 3 solution, stirred at room temperature for 3 h, then centrifuged to remove excess Ag + , and finally the washed product was dried in a vacuum oven at 60°C for 24 hours to obtain Ag / Ti with an Ag content of 0.2wt%. 3 C 2 T x Sheet composites.

Embodiment 3

[0038] Preparation of a Ag / MXene Flake Composite

[0039] Compared with Example 1, the difference is only that S3 is different, and the rest are the same, specifically: S3, taking a certain amount of AgNO 3 Dissolved in 50ml deionized water to prepare AgNO 3 solution, 1g Ti 3 C 2 T x The flakes were slowly added to the above AgNO 3 solution, stirred at room temperature for 9 h, and then centrifuged to remove excess Ag + , and finally the washed product was dried in a vacuum oven at 60°C for 24 hours to obtain Ag / Ti with an Ag content of 2.0wt%. 3 C 2 T x Sheet composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com