Modified acrylic resin emulsion and preparation method thereof

A technology of acrylic resin and acrylate, which is applied in the direction of coating, etc., can solve the problems of the environment, the hazards of the staff, the difficulty of increasing the grafting rate, and the unfavorable long-term development, so as to reduce air pollution, reduce oil floating, and improve The effect of grafting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

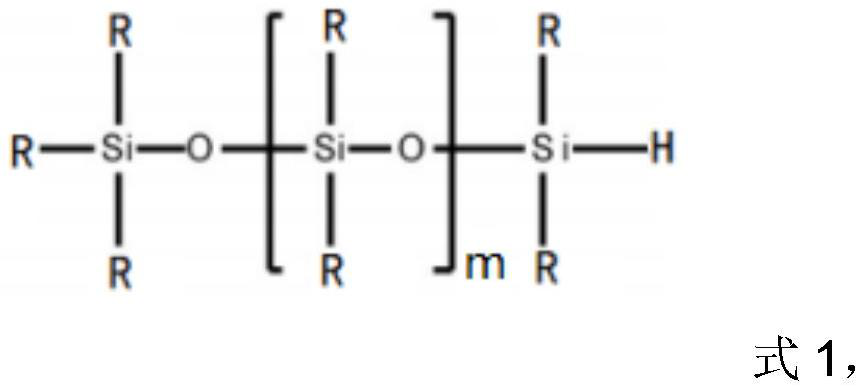

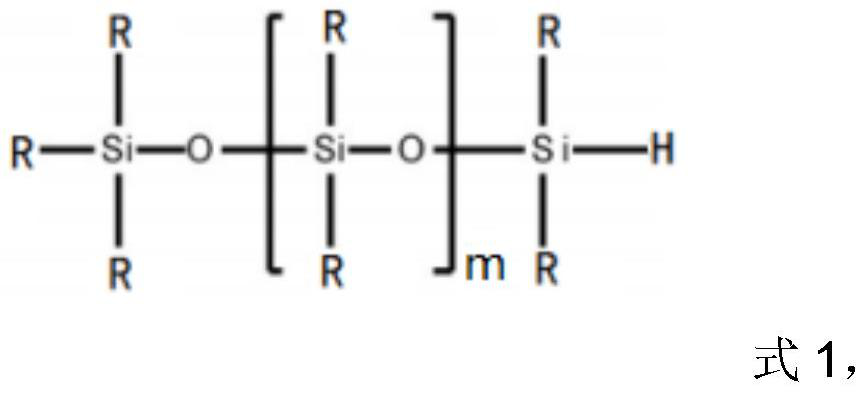

[0064] Under the condition of nitrogen protection, mix 12.7g of allyl methacrylate, 100g of silicone oil containing a silicon hydrogen group at one end, 0.006g of polymerization inhibitor p-hydroxyanisole and 0.6g of 5000ppm Castel platinum catalyst, at 40°C After reacting for 10 hours, and then distilling under reduced pressure, polysiloxane with free radical polymerizable unsaturated groups was obtained, with a yield of 99%. After testing, its viscosity was 13 mPa.s, the number average molecular weight was 1130, and the vinyl content 2.3%, hydrogen content is 0;

[0065] The preparation method of the silicone oil containing a silicon hydrogen group at one end is:

[0066] Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 5.4g of concentrated sulfuric acid and 600g of toluene and slowly raise the temperature to 75°C, react for 3 hours, add 45g of potassium trimethylsiliconate and 270g of THF and raise the temperature to 80°C for 10 hours , cooled to ro...

Embodiment 2

[0068] Under the condition of nitrogen protection, mix 11.3g of allyl acrylate, 100g of silicone oil containing a silicon hydrogen group at one end, 0.006g of polymerization inhibitor p-hydroxyanisole and 0.7g of 5000ppm Castel platinum catalyst, and react at 40°C for 8h. Distilled under reduced pressure to obtain polysiloxane with unsaturated groups that can be radically polymerized, with a yield of 99%, a viscosity of 12 mPa.s, a number average molecular weight of 1112, and a vinyl content of 2.4%. , the hydrogen content is 0;

[0069] The preparation method of the silicone oil containing a silicon hydrogen group at one end is the same as in Example 1.

Embodiment 3

[0071] Under the condition of nitrogen protection, mix 4.7g of allyl methacrylate, 100g of silicone oil containing a silicon hydrogen group at one end, 0.25g of polymerization inhibitor p-hydroxyanisole and 0.27g of 5000ppm Castel platinum catalyst, and react at 60°C 8h, and then through vacuum distillation to obtain polysiloxane with free radical polymerizable unsaturated groups, the yield is 99%, its viscosity is 30mPa.s after testing, the number average molecular weight is 2830, the vinyl content 0.91%, hydrogen content is 0;

[0072] The preparation method of the silicone oil containing a silicon hydrogen group at one end is:

[0073]Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 0.9g of trifluoromethanesulfonic acid and 90g of toluene and slowly raise the temperature to 75°C, add 15g of potassium trimethylsiliconate and 45g of THF and raise the temperature to 80°C after 3 hours of reaction React at ℃ for 10 hours, cool to room temperature, add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com