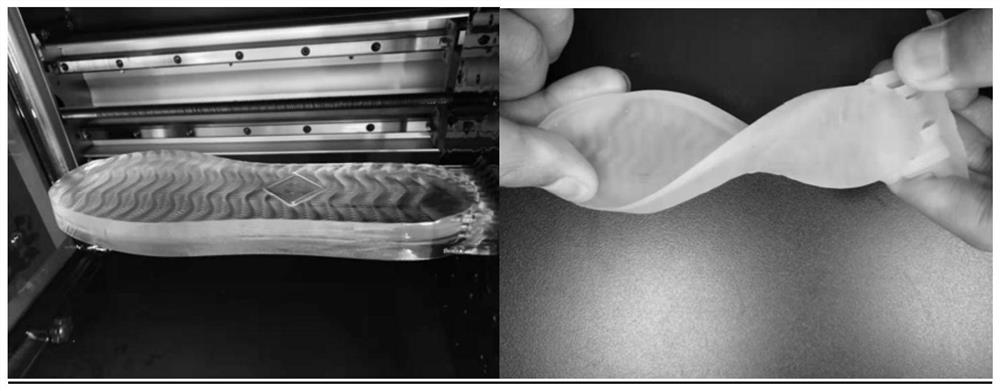

Photosensitive resin composition for photocuring 3D printing elastomer and preparation method thereof

A 3D printing, photosensitive resin technology, applied in the chemical industry, can solve the problems of high cost, insufficient tensile strength and elongation at break, and achieve the effect of reducing material usage costs, breaking technology monopoly, and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

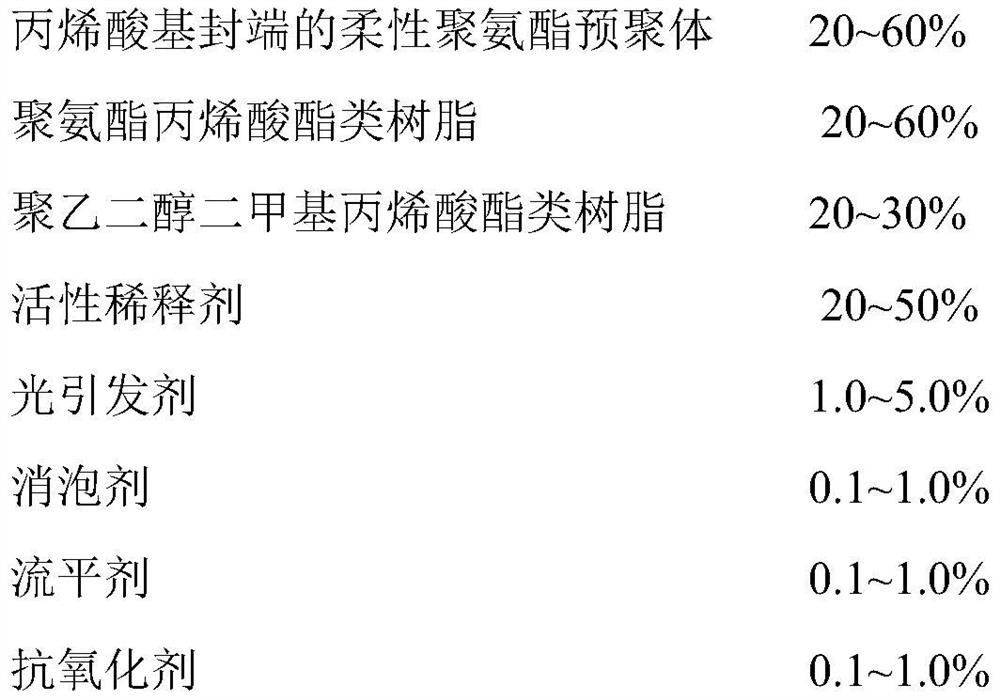

[0059] The preparation of embodiment 1 sample 1#~sample 6#, preparation steps are as follows:

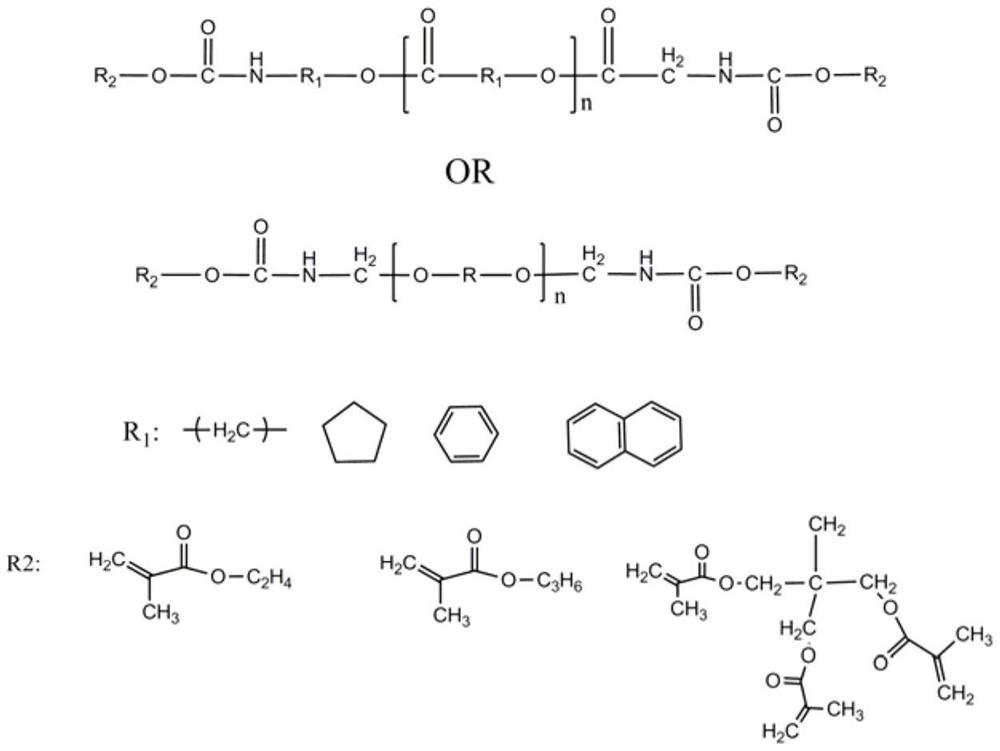

[0060] (1) In a round-bottomed flask equipped with isocyanate-terminated polyester (ether), continuously drop and measure hydroxyl-containing acrylic monomers through a separatory funnel, and react under nitrogen protection and 50-100°C 0.1-7.0h;

[0061] (2) Vacuumize and defoam the reacted product to obtain a flexible polyurethane photosensitive prepolymer terminated by acrylic acid groups;

[0062] (3) In terms of percentage content, 20-60% of acrylic group-terminated polyester (ether), 20-60% of acrylic resin, 20-30% of polyethylene glycol dimethacrylate resin, 20-60% Mix 50% active diluent, 1.0-5.0% photoinitiator, 0.1-1.0% defoamer, 0.1-1.0% leveling agent, 0.1-1.0% antioxidant and heat up to 30-80°C, after mixing evenly, That is, a photosensitive resin composition for photocuring 3D printing elastomers is obtained.

[0063] The relationship between the sample number and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com