Cold heading forming device of thin-wall hollow positioning pin and forming method of cold heading forming device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

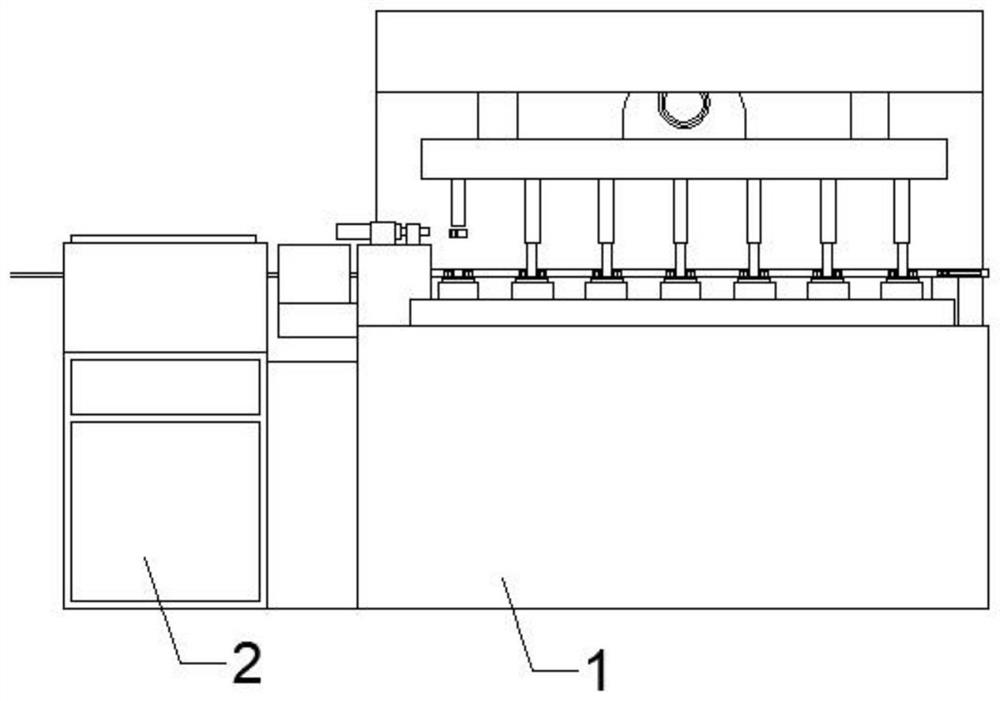

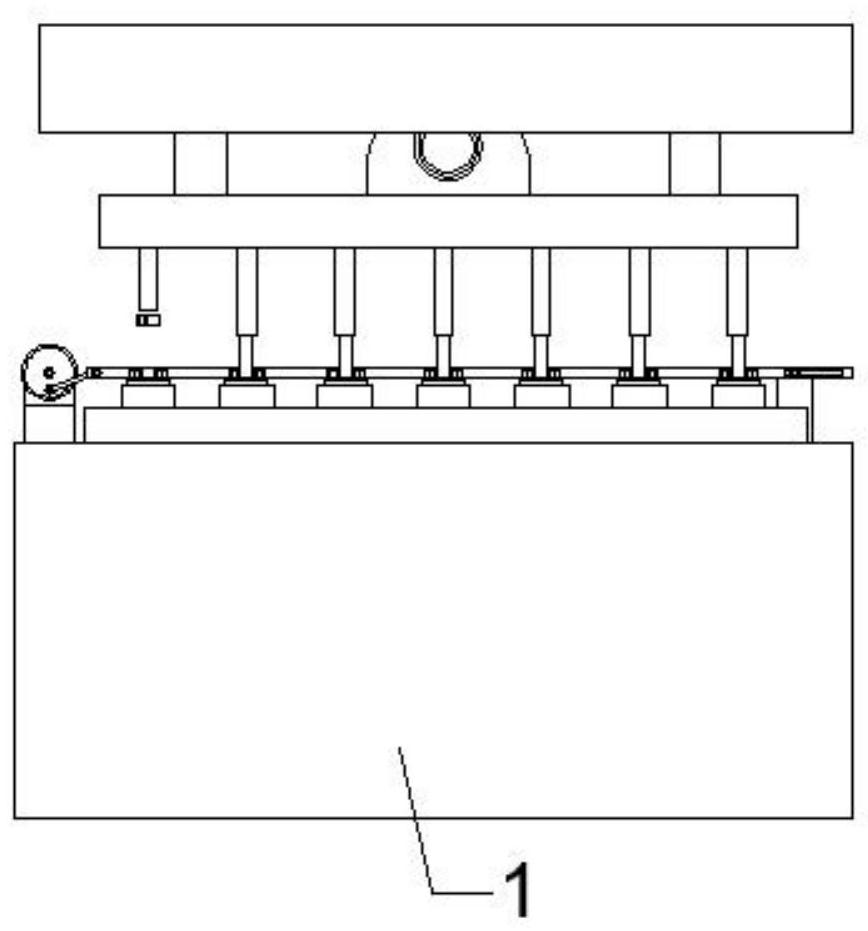

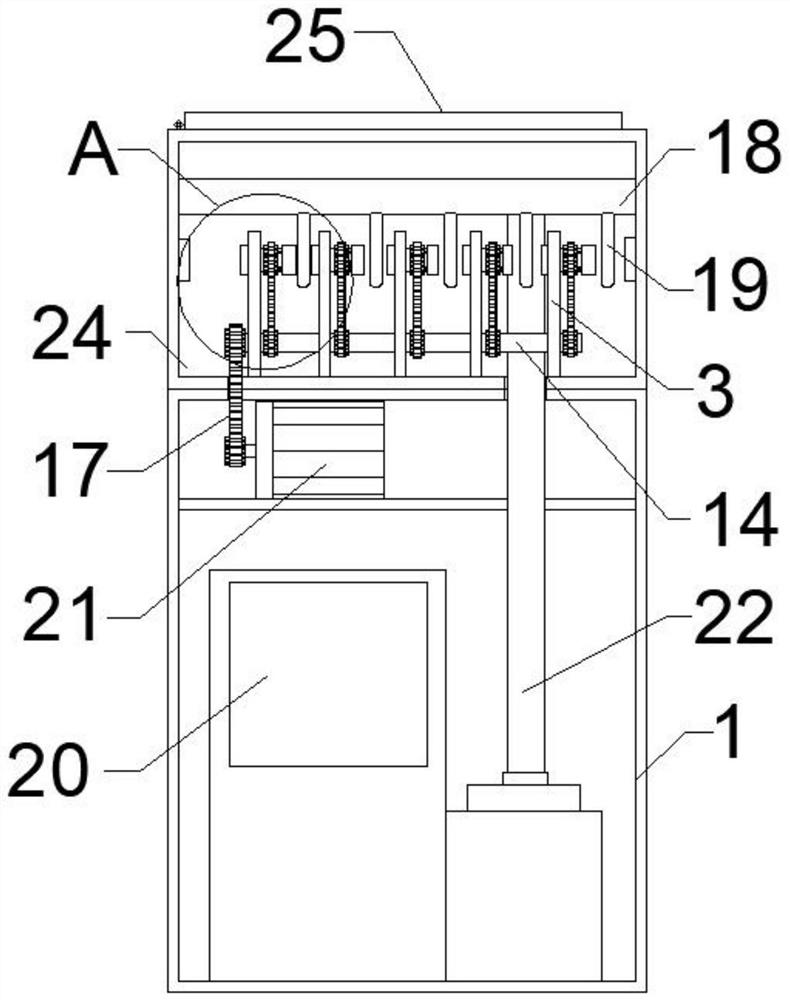

[0032] Such as Figure 1-7 As shown, a cold heading forming device of a thin-walled hollow positioning pin includes a cold heading machine 1 and a powder removal box 2, and also includes a steel pipe 4, a dust removal sleeve 6, a dust collection pipe 18 and a metal rod 14. The powder removal box 2 is assembled on the feed end of the cold heading machine 1 through bolts, and the inner top of the powder removal box 2 is separated by steel plate welding to separate the cleaning room 24, the metal rod 14 is located at the bottom of the cleaning room 24, and the dust collection pipe 18 is arranged on the top of the cleaning room 24, and the cleaning room 24 is arranged with a dust removal cover 6 in turn, and one end of the dust removal cover 6 is provided with a plug joint 7, and the dust removal cover 6 is connected to one end of the steel pipe 4 through the plug joint 7 Plug-in connection, one end of the steel pipe 4 and the plug joint 7 are provided with corresponding first bol...

Embodiment 2

[0047] Such as Figure 1-7 As shown, a cold heading forming device of a thin-walled hollow positioning pin includes a cold heading machine 1 and a powder removal box 2, and also includes a steel pipe 4, a dust removal sleeve 6, a dust collection pipe 18 and a metal rod 14. The powder removal The box 2 is assembled on the feed end of the cold heading machine 1 through bolts. The top of the powder removal box 2 is welded with a steel plate to separate a cleaning room 24. The metal rod 14 is located at the bottom of the cleaning room 24. The dust collecting The pipe 18 is arranged on the top of the cleaning chamber 24, and the cleaning chamber 24 is sequentially provided with a dust removal cover 6, and one end of the dust removal cover 6 is provided with a plug joint 7, and the dust removal cover 6 is connected to the steel pipe 4 through the plug joint 7. One end is plugged and connected, and one end of the steel pipe 4 and the plug joint 7 are provided with corresponding first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com