Steel ladle concrete beam additional steel plate cavity post-grouting fireproof structure and method thereof

A steel-clad concrete and fire-proof structure technology, which is applied in the direction of fire prevention, structural elements, and long-strip structural members for load-bearing, etc., can solve the problems of difficult fire protection performance, easy cracking and falling off, and high maintenance costs, so as to delay the time of cracking and falling off , Avoid high-altitude operations, good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

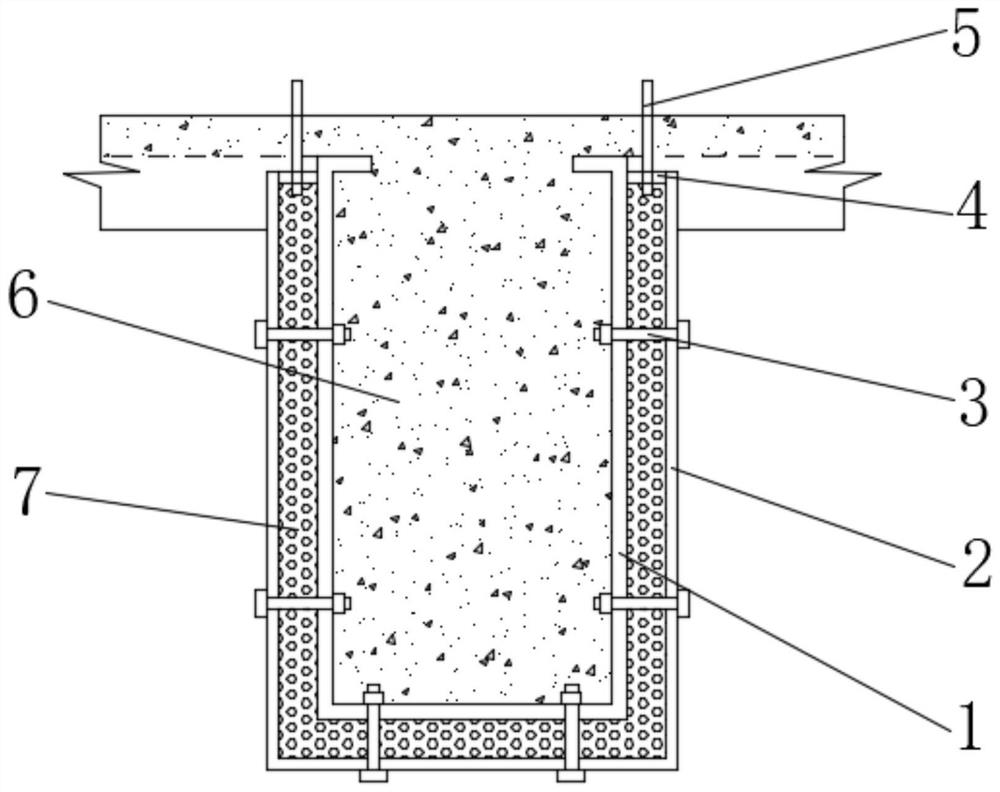

[0036] see figure 1 A steel-clad concrete beam additional steel plate cavity post-grouting fireproof structure, comprising a structural beam-encapsulating steel plate 1 and an additional steel plate 2; The additional steel plates 2 are connected by stainless steel bolts 3, the structural beam-wrapping steel plate 1 is filled with cast-in-place concrete 6 in the ladle beam, and the gap between the structural beam-wrapping steel plate 1 and the additional steel plate 2 is filled with the same Cement mortar layer for structural beam concrete strength class 7.

[0037] In the embodiment of the present invention, the additional steel plate 2 is wrapped in a U shape on the outside of the structural beam steel plate 1, and the thickness of the additional steel plate 2 is 1mm, and the outer wall of the additional steel plate 2 is coated with antirust paint.

[0038] In the embodiment of the present invention, the additional steel plate 2 is provided with a rubber pad 4 at the joint b...

Embodiment 2

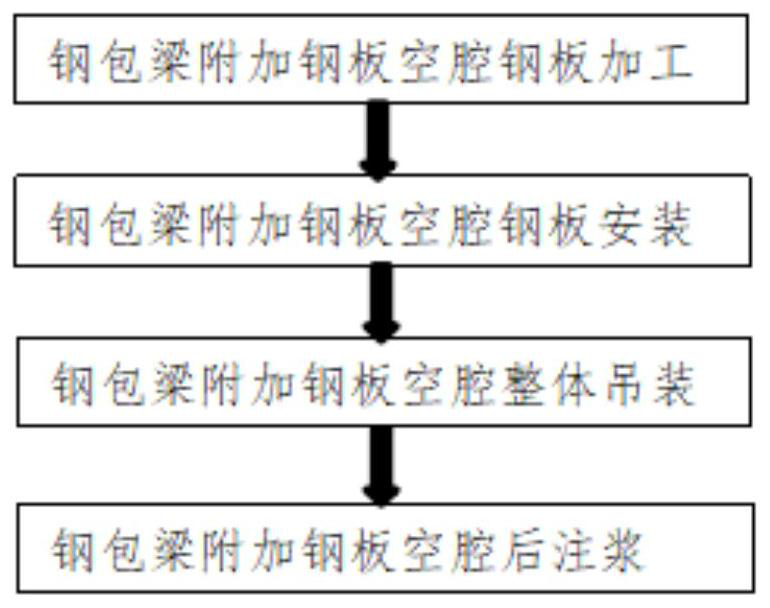

[0043] see figure 2 , a construction method of grouting a fireproof structure after a steel plate cavity is attached to a steel-clad concrete beam, the construction method comprising the following steps:

[0044] Step 1. Ladle beam additional steel plate cavity steel plate processing: According to the size of the ladle beam, the top and beam ends are retracted by 2cm. The outer surface size of the cavity is processed as an additional steel plate, and the beam top and beam end flanges are the same as the thickness of the cavity;

[0045] Step 2. Ladle beam additional steel plate cavity steel plate installation: Considering that the process of transportation is easy to damage the outer steel, it is preferred to use on-site installation before lifting.

[0046] ① M5 stainless steel bolts are used to connect the stressed channel steel and the additional cavity steel plate, the spacing is not greater than 1m, and the outsourcing steel is evenly arranged along the structure, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com