Quick-setting road marking paint with noctilucent marking effect and preparation method thereof

A line marking paint and optical marking technology, which is applied in the direction of luminous paint, coating, conjugated diene coating, etc., can solve the problems of short service life of marking paint, uneven distribution of luminescent materials, and easy breakage of luminescent materials. Achieve good environmental protection, good integration, and good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

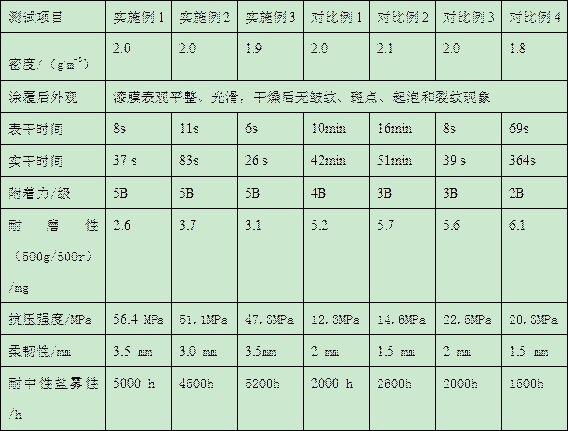

Examples

preparation example Construction

[0037] A preparation method of a quick-setting road marking paint with luminous marking effect, comprising the following steps:

[0038] (1) Preparation of surface-coated luminous material

[0039] Take the luminous luminous material particles and place them in the binder, stir and mix them evenly, so that the surface of the luminous luminous material is evenly coated with the adhesive, then transfer them to the glass powder, so that the surface is evenly covered with glass powder, and then, The obtained granular material is placed in a kiln, fired at 800-1100°C for 0.5-1.5 hours, cooled naturally and then taken out of the kiln to obtain a surface-coated luminous material, which is ready for use;

[0040] (2) Preparation of ingredient A

[0041] According to the parts by weight, weigh 110-200 parts of bisphenol A epoxy resin, 60-90 parts of acrylic resin, 90-160 parts of styrene-butadiene transparent impact resin and 40-60 parts of dimethyl phosphate and place them together u...

Embodiment 1

[0047] A preparation method of a quick-setting road marking paint with luminous marking effect, comprising the following steps:

[0048] (1) Preparation of surface-coated luminous material

[0049] Take 100kg of light-storing luminescent material particles with a particle size of 10-50mm and place them in 8kg of binder a-cyanoacrylate, stir and mix thoroughly, then transfer the obtained materials to 40kg of glass powder to make the surface evenly coated Cover the glass powder, after that, dry the obtained granular material from the glass powder, put the obtained granular material in the kiln, and fire it at 1000 ° C for 1 hour, and leave the kiln after natural cooling to obtain the surface-coated material. Overlay luminous material, spare;

[0050] (2) Preparation of ingredient A

[0051] According to the parts by weight, take respectively 200 parts of bisphenol A type epoxy resin, 70 parts of acrylic resin, 120 parts of styrene-butadiene transparent impact-resistant resin a...

Embodiment 2

[0057] A preparation method of a quick-setting road marking paint with luminous marking effect, comprising the following steps:

[0058] (1) Preparation of surface-coated luminous material

[0059] Take 100kg of light-storing luminescent material particles with a particle size of 10-50mm and place them in 10kg of binder acrylic polymer, stir and mix thoroughly, then transfer the obtained material into 40kg of glass powder, so that the surface is evenly coated with glass powder After that, the obtained granular material is dried out from the glass powder, and the obtained granular material is placed in a kiln, fired at 1100°C for 0.5h, cooled naturally, and then discharged from the kiln to obtain a surface-coated Luminous material, spare;

[0060] (2) Preparation of ingredient A

[0061] According to the parts by weight, take respectively 110 parts of bisphenol A type epoxy resin, 90 parts of acrylic resin, 90 parts of styrene-butadiene transparent impact-resistant resin and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com