Preparation method of heavy calcium carbonate for high-activation-degree silicone adhesive

A heavy calcium carbonate, activation degree technology, applied in chemical instruments and methods, adhesives, dyeing organosilicon compound treatment, etc., can solve the problems of single-component modifier with single effect, poor modification effect and high preparation cost, To achieve the effect of simple and easy preparation method, low oil absorption value and low specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

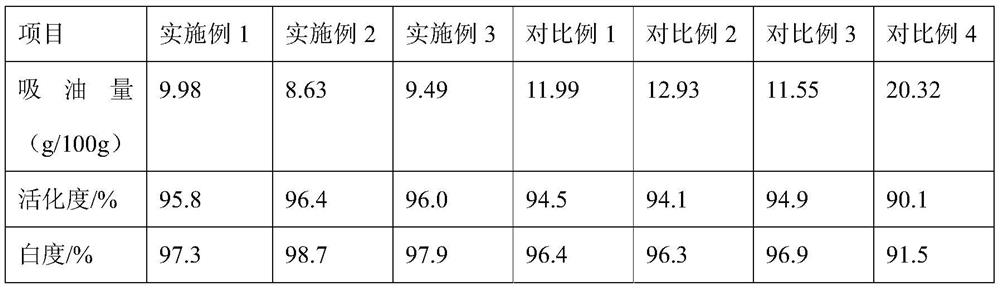

Examples

Embodiment 1

[0032] A method for preparing heavy calcium carbonate for high-activation silicone rubber, which sequentially includes ore storage, cleaning, mineral processing, crushing and homogenization, grinding, grading, powder collection, quality inspection I, activation, cooling, and quality inspection II steps ;

[0033] The described ore storage steps are: storing the ore raw materials separately according to ore types and grades;

[0034] The cleaning steps are: cleaning the mud stuck on the surface of the ore with water;

[0035]The ore dressing step is: selecting the unqualified ore entrained in the ore; the unqualified ore is the ore with low whiteness, skin and other impurities;

[0036] The crushing and homogenizing step is as follows: crush the qualified ore into 18mm ore, and then send it into a 10,000-ton level homogenizing tank for homogenizing;

[0037] The grinding step is: sending the mineral material into the grinding equipment for grinding;

[0038] The grading step...

Embodiment 2

[0045] A preparation method of heavy calcium carbonate for high-activation silicone rubber, which sequentially includes ore storage, cleaning, beneficiation, crushing and homogenization, grinding, grading, powder collection, quality inspection I, activation, cooling, and quality inspection II steps ;

[0046] The described ore storage steps are: storing the ore raw materials separately according to ore types and grades;

[0047] The cleaning steps are: cleaning the mud stuck on the surface of the ore with water;

[0048] The ore dressing step is: selecting the unqualified ore entrained in the ore; the unqualified ore is the ore with low whiteness, skin and other impurities;

[0049] The crushing and homogenizing step is as follows: crushing the qualified ore into 15mm ore, and then sending it into a 10,000-ton level homogenizing tank for homogenizing;

[0050] The grinding step is: sending the mineral material into the grinding equipment for grinding;

[0051] The grading s...

Embodiment 3

[0058] A preparation method of heavy calcium carbonate for high-activation silicone rubber, which sequentially includes ore storage, cleaning, beneficiation, crushing and homogenization, grinding, grading, powder collection, quality inspection I, activation, cooling, and quality inspection II steps ;

[0059] The described ore storage steps are: storing the ore raw materials separately according to ore types and grades;

[0060] The cleaning steps are: cleaning the mud stuck on the surface of the ore with water;

[0061] The ore dressing step is: selecting the unqualified ore entrained in the ore; the unqualified ore is the ore with low whiteness, skin and other impurities;

[0062] The crushing and homogenizing step is as follows: crush the qualified ore into a 10mm mineral material, and then send it into a 10,000-ton level homogenizing tank for homogenizing;

[0063] The grinding step is: sending the mineral material into the grinding equipment for grinding;

[0064] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com