High-ammonia-nitrogen waste liquid purification process

A purification process, high ammonia nitrogen technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, separation methods, etc. The effect of high elasticity and strong shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

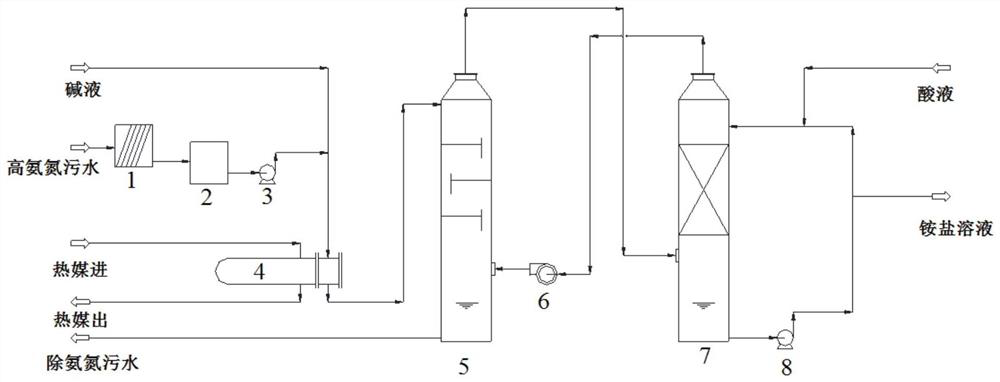

Method used

Image

Examples

Embodiment 1

[0035] 15L of waste liquid containing 4000mg / L of ammonia nitrogen is first pretreated by grille and sedimentation tank, and NaOH solution is added to the inlet pipe of the heat exchanger to adjust the pH to 11, and the temperature of high ammonia nitrogen waste liquid is raised to 65°C. Then it enters the plate blowing tower. The upper part of the blowing tower is equipped with a tubular liquid distributor, and the bottom of the tower is equipped with a blower to blow in circulating air for gas-liquid contact and mass transfer. The waste liquid at the bottom of the tower is discharged through the drainage pump, and undergoes crystallization, dehydration, and drying to obtain solid products and complete the recovery of ammonia nitrogen resources. The concentration of ammonia nitrogen in the effluent measured at this time was 120 mg / L, and the removal rate of ammonia nitrogen was about 97%.

Embodiment 2

[0037] 20L of waste liquid containing 6300mg / L of ammonia nitrogen is firstly pretreated by grille and sedimentation tank, and then KOH is added to the alkali addition tank with stirring to adjust the pH to 12, and then the temperature of high ammonia nitrogen waste liquid is raised to 70°C. After that, it enters the packed blow-off tower. The upper part of the blow-off tower is equipped with a trough-type liquid distributor, the tower is filled with Pall rings, and the bottom of the tower is equipped with a blower to blow in circulating nitrogen. Entering the absorption tower with pH=5, the waste liquid at the bottom of the stripping tower is discharged through the drainage pump, and undergoes crystallization, dehydration, and drying to obtain solid products and complete the recovery of ammonia nitrogen resources. The concentration of ammonia nitrogen in the effluent measured at this time was 125 mg / L, and the removal rate of ammonia nitrogen was about 98%.

Embodiment 3

[0039] 25L of ammonia nitrogen containing 5800mg / L waste liquid is first pretreated by grille and sedimentation tank, and NaOH solution is added to the inlet pipe of the heat exchanger to adjust the pH to 13, and the temperature of high ammonia nitrogen waste liquid is raised to 85°C. After entering the plate type stripping tower, the upper part of the stripping tower is equipped with a jet liquid distributor, and the bottom of the tower is equipped with a blower to blow in circulating nitrogen for gas-liquid contact mass transfer. The waste liquid at the bottom of the tower is discharged through the drainage pump, and undergoes crystallization, dehydration, and drying to obtain solid products and complete the recovery of ammonia nitrogen resources. The ammonia nitrogen concentration in the effluent measured at this time was 170mg / L, and the removal rate of ammonia nitrogen was about 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com