High-purity magnesium strip line anchor and implanting device thereof

An implanting device and anchor technology are applied in the field of high-purity magnesium strip wire anchors and implanting devices, which can solve problems such as hidden dangers of magnesium alloy safety, and achieve the effects of good biocompatibility, high mechanical strength and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

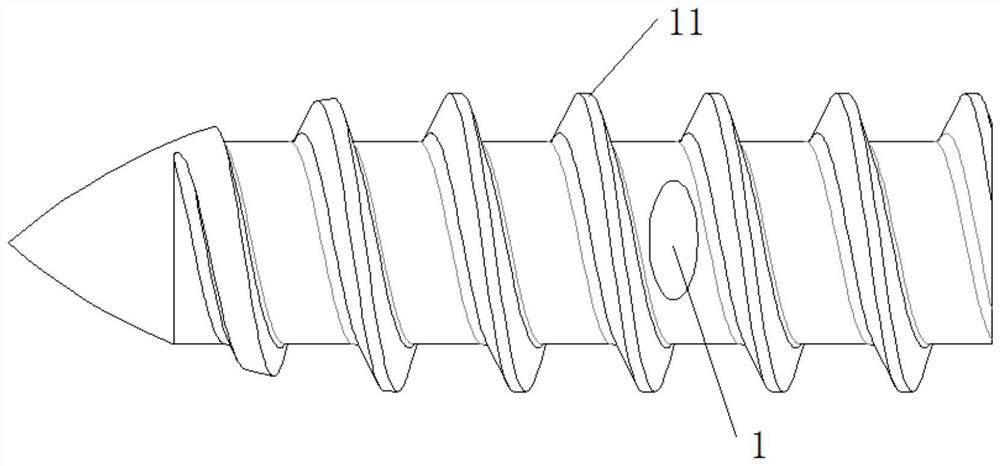

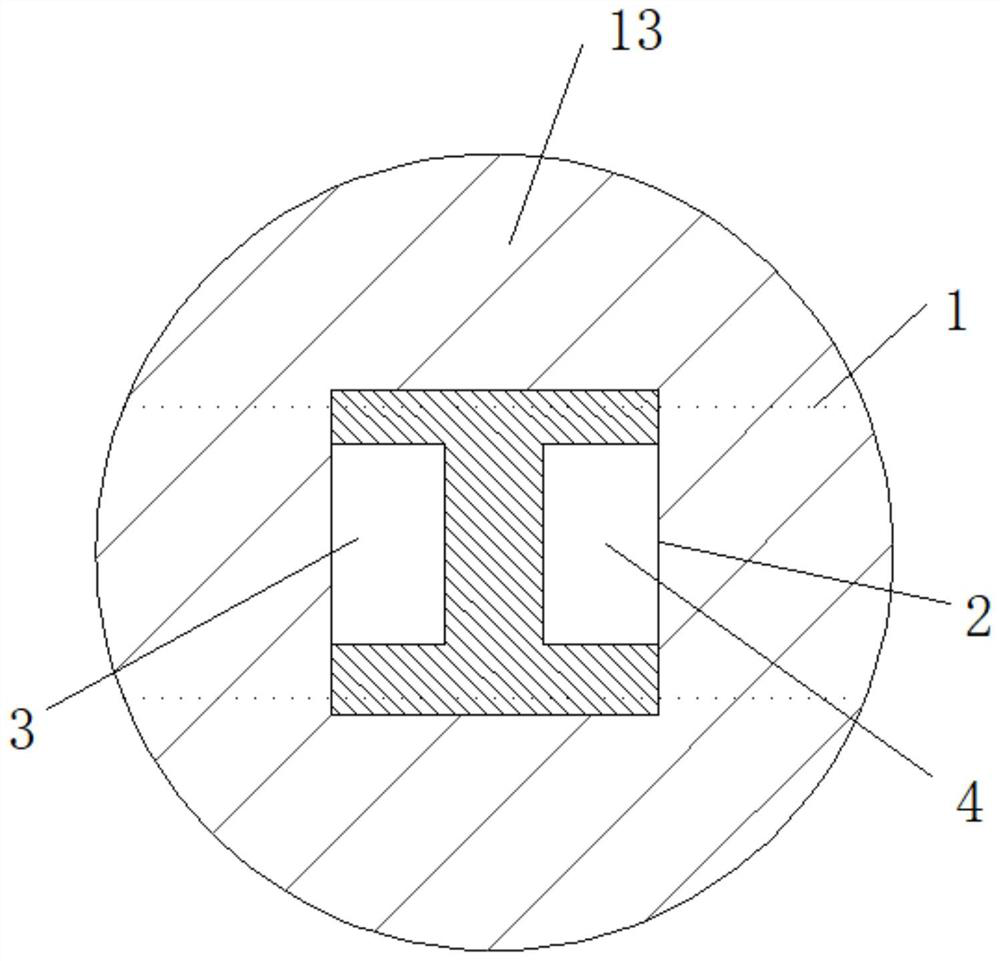

[0040] A high-purity magnesium wire anchor ( figure 1), including an anchor body 13, the anchor body is provided with a through hole 1 that runs through the anchor body in the width direction, and the center of the rear end of the anchor body is provided with a mounting hole 2, and the bottom of the mounting hole A threading hole is provided, and the threading hole includes a left threading hole 3 and a right threading hole 4, and the mounting hole communicates with the through hole through the left threading hole and the right threading hole, and the mounting hole is a square hole; The shape is rectangular ( figure 2 ). The outer surface of the anchor body is provided with threads 11, and the through hole is located near the rear end of the anchor body and is located in the thread groove. The purity of high-purity magnesium is above 99.98wt%.

[0041] An implant device matched with the high-purity magnesium wire anchor ( Figure 5 ), including a connecting rod 5 and a ha...

Embodiment 2

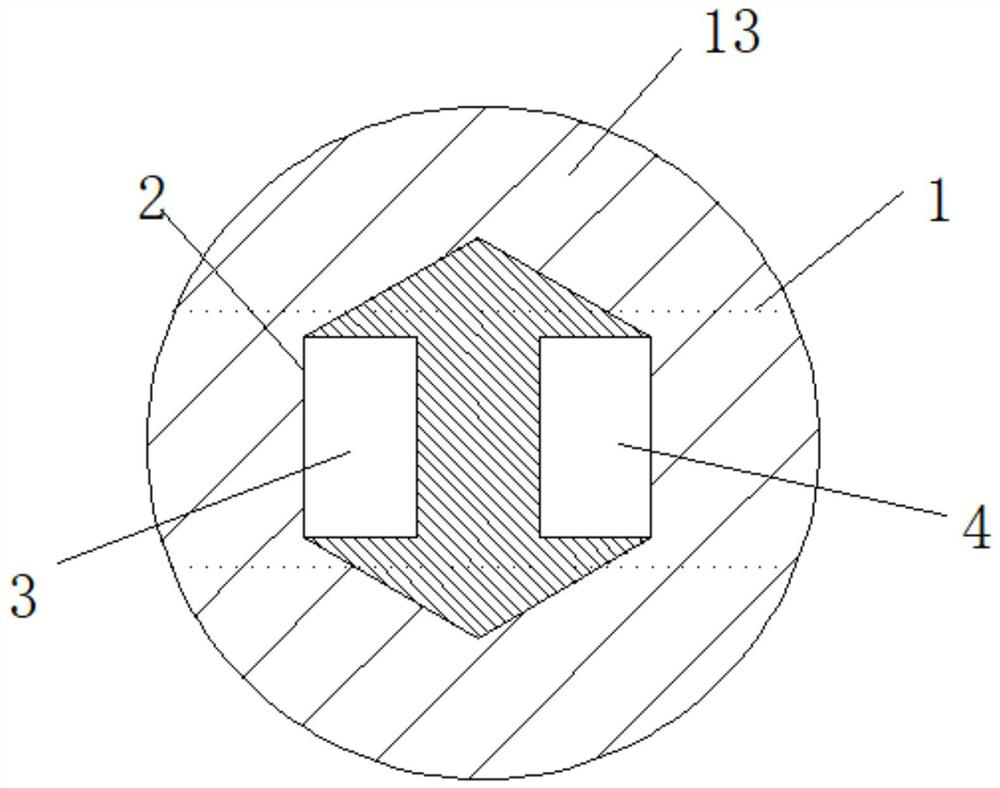

[0043] A high-purity magnesium wire anchor ( figure 1 ), including an anchor body 13, the anchor body is provided with a through hole 1 that runs through the anchor body in the width direction, and the center of the rear end of the anchor body is provided with a mounting hole 2, and the bottom of the mounting hole A threading hole is provided, and the threading hole includes a left threading hole 3 and a right threading hole 4, and the mounting hole communicates with the through hole through the left threading hole and the right threading hole, and the mounting hole is an inner hexagonal hole; the threading hole The shape is rectangular ( image 3 ). The outer surface of the anchor body is provided with threads 11, and the through hole is located near the rear end of the anchor body and is located in the thread groove. The purity of high-purity magnesium is above 99.98wt%.

[0044] An implant device matched with the high-purity magnesium wire anchor ( Figure 5 ), includin...

Embodiment 3

[0046] A high-purity magnesium wire anchor ( figure 1 ), including an anchor body 13, the anchor body is provided with a through hole 1 that runs through the anchor body in the width direction, and the center of the rear end of the anchor body is provided with a mounting hole 2, and the bottom of the mounting hole A threading hole is provided, and the threading hole includes a left threading hole 3 and a right threading hole 4, and the mounting hole communicates with the through hole through the left threading hole and the right threading hole, and the mounting hole is a square hole; round in shape ( Figure 4 ). The outer surface of the anchor body is provided with threads 11, and the through hole is located near the rear end of the anchor body and is located in the thread groove. The purity of high-purity magnesium is above 99.98wt%.

[0047] An implant device matched with the high-purity magnesium wire anchor ( Figure 5 ), including a connecting rod 5 and a handle 6, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com