Method for preparing natural hesperidin through biological fermentation and extraction

A bio-fermentation and hesperidin technology, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, sugar derivative preparation, etc., can solve the problems of slow extraction rate, easy temperature rise, unfavorable hesperidin stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

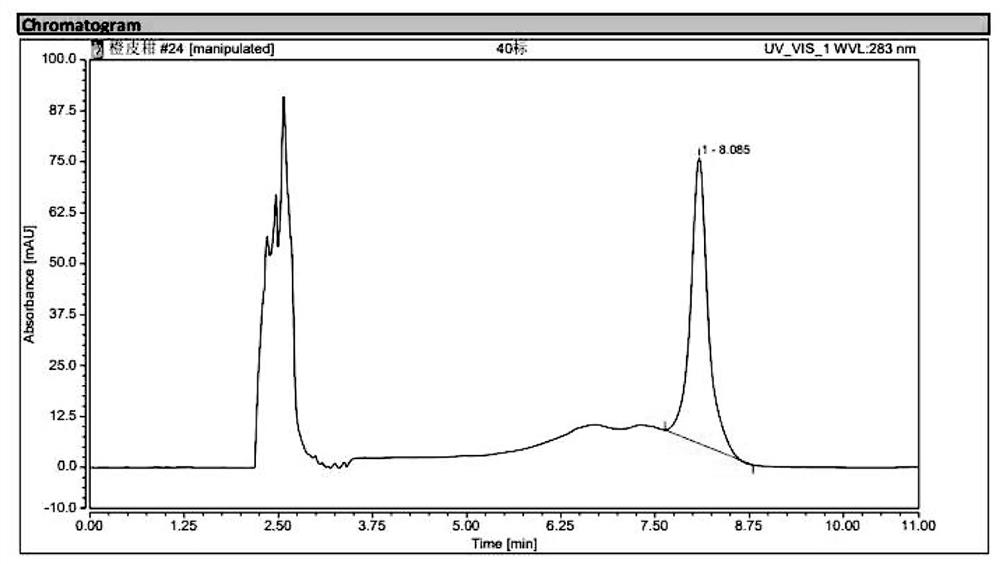

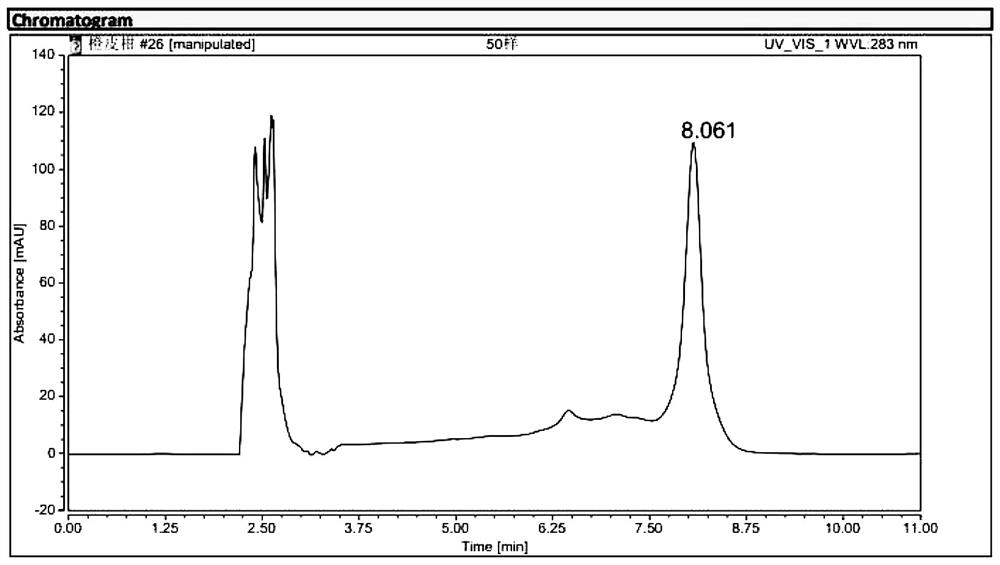

Image

Examples

Embodiment 1

[0028] Prepare the culture medium in the fermenter, soluble starch 10g / L, glycerin 2g / L, soybean meal 10g / L, yeast powder 5g / L, soybean polypeptide powder 1.5g / L, dibutylhydroxytoluene 0.1g / L, magnesium sulfate 0.1g / L, zinc chloride 0.05g / L; fresh orange peel and culture medium were mixed according to the ratio of 1:1, the steam pressure was increased to 0.5 MPa, and the pressure was maintained at this pressure for 6min, and then a large amount of steam was introduced at one time. pressure, always raise the pressure to 1.0MPa, and blast; in the growth stage of the bacteria, inoculate the fermenter with 1% inoculum of Aspergillus niger ATCC16404, 1% of inoculation with Aspergillus oryzae ATCC 42149, and 1% of inoculum with subtilis Bacillus ATCC6051, 1% inoculum amount was used to inoculate yeast ATCC 9763, the temperature was controlled at 30°C, the ventilation volume was 0.3VVM, and the culture time was 18 hours; the ventilation volume was adjusted to 0.2VVM, and the pH value ...

Embodiment 2

[0030] Prepare the culture medium in the fermenter, soluble starch 10g / L, glycerin 2g / L, soybean meal 10g / L, yeast powder 5g / L, soybean polypeptide powder 1g / L, dibutylhydroxytoluene 0.1g / L, magnesium sulfate 0.1 g / L, zinc chloride 0.05g / L; fresh orange peel and culture medium are mixed according to the ratio of 1:1, and the steam is boosted to 1.0MPa before blasting; in the growth stage of the bacteria, the inoculum is inoculated according to 1% of the inoculum Aspergillus niger ATCC16404, 1% of the inoculum was inoculated with Aspergillus oryzae ATCC 42149, 1% of the inoculum was inoculated with Bacillus subtilis ATCC 6051, 1% of the inoculum was inoculated with yeast ATCC 9763, the temperature was controlled at 30°C, the ventilation rate was 0.3VVM, and the culture time 18 hours; in the enzymatic hydrolysis stage of orange peel, adjust the ventilation rate to 0.2VVM, adjust the pH value to 4.0, first control the temperature at 15°C, and maintain it for 6 hours, then adjust t...

Embodiment 3

[0032] Configure the culture medium in the fermenter, soluble starch 12g / L, glycerin 3g / L, soybean meal 12 g / L, yeast powder 8 g / L, soybean polypeptide powder 1.5g / L, dibutylhydroxytoluene 0.15 / L, sulfuric acid Magnesium 0.15g / L, zinc chloride 0.08g / L; fresh orange peel and culture medium are mixed according to the ratio of 1:1.2, the steam is pressurized to 0.7 MPa, and the pressure is maintained at this pressure for 8 minutes, and then a large amount of steam is injected at one time Boost the pressure, raise the pressure to 1.2MPa, and then blast; in the growth stage, inoculate the fermenter with 2% inoculum of Aspergillus niger ATCC16404, 2% of inoculation with Aspergillus oryzae ATCC 42149, 2% of inoculum Inoculate Bacillus subtilis ATCC 6051, inoculate yeast ATCC 9763 with 1.5% inoculum, control the temperature at 35°C, aeration 0.5VVM, and cultivate for 24 hours; during the enzymatic hydrolysis stage of orange peel, adjust the aeration to 0.3VVM and adjust the pH value 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com