Sewage treatment and slag recycling process for production of iron phosphate by sodium method

A sewage treatment, iron phosphate technology, applied in the chemical industry, to achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

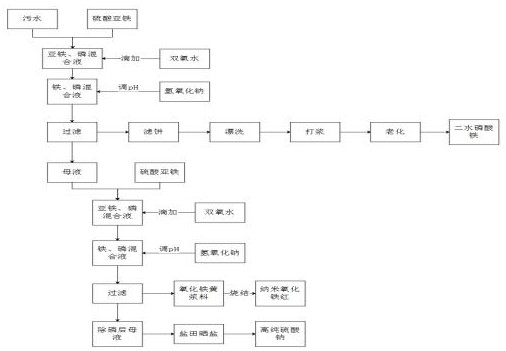

Method used

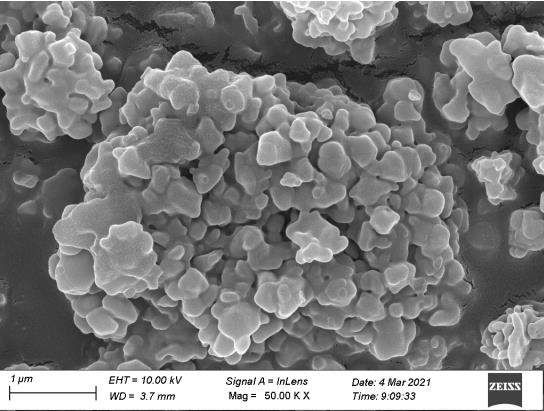

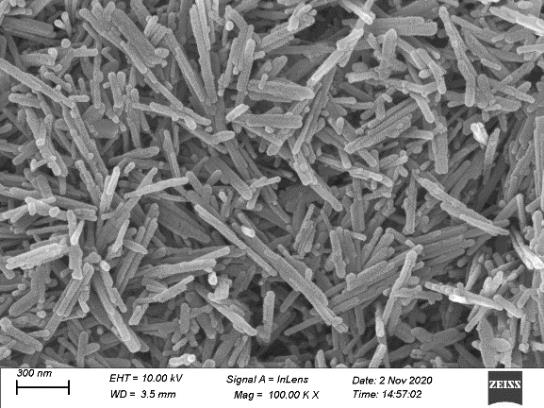

Image

Examples

Embodiment 1

[0028] This example provides a kind of sewage treatment and slag recycling process of producing ferric phosphate by sodium method, and its specific steps include:

[0029] Step 1: Measure the phosphorus content in the sewage, and calculate the amount of ferrous sulfate added according to the phosphorus content, so that the molar ratio of ferrous: phosphorus in the sewage is 1:1.02.

[0030] Step 2: Add hydrogen peroxide dropwise to the solution obtained in step 1. The molar ratio of the added hydrogen peroxide to the ferrous ion in step (1) is 0.6:1. Iron ions are oxidized to iron ions.

[0031] Step 3: Adjust the pH value of the solution obtained in step 2 to 3 with a sodium hydroxide solution with a volume fraction or mass fraction of 8%. The dropwise addition time of sodium hydroxide is 30 minutes, and a precipitation reaction occurs while stirring is maintained during the dropwise addition.

[0032] Step 4: Filter the reaction solution obtained in step 5 to obtain a first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com