Method for preparing micro-nano periodic structures on the surface of amorphous alloys by nanosecond laser irradiation

A periodic structure and amorphous alloy technology, applied in laser welding equipment, nanotechnology, welding equipment, etc., can solve the problems of difficult to achieve industrial production, complex femtosecond laser processing process, high cost, etc., and achieve low cost and high processing cost. Simple method, effect of periodic structure rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for preparing the micro-nano periodic structure on the surface of the amorphous alloy by nanosecond laser irradiation in this embodiment, the specific implementation steps are as follows:

[0032] (1) The Zr to be processed 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The amorphous alloy samples were mechanically ground and polished, and ultrasonically cleaned with ethanol and deionized water for about 10 minutes at a temperature of 50-60°C, and then air-dried at room temperature.

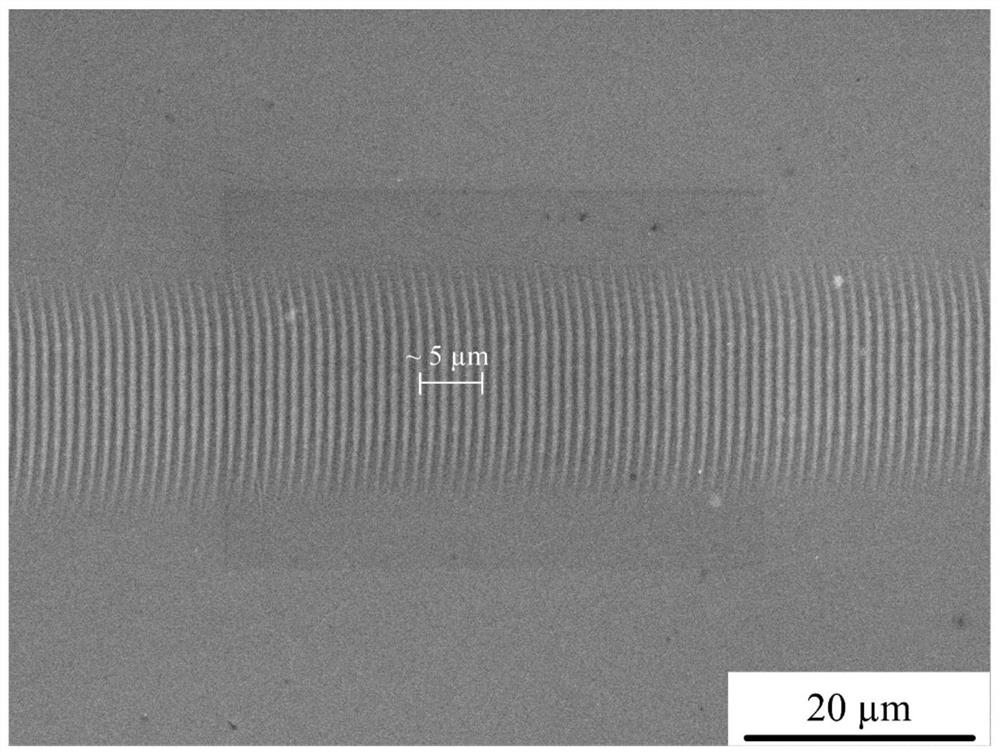

[0033] (2) Using argon as a shielding gas, the laser beam is focused on the surface of the amorphous alloy, the laser irradiation parameters are set by a computer program, and then the laser irradiation is performed to form a periodic micro-nano structure on the surface. The laser irradiation process parameters used are: argon pressure is 0.01MPa, laser wavelength is 1064nm, pulse width is 7ns, repetition frequency is 600kHz, and laser energy density is 60mJ / cm 2 , the scanning speed i...

Embodiment 2

[0036] The method for preparing the micro-nano periodic structure on the surface of the amorphous alloy by nanosecond laser irradiation in this embodiment, the specific implementation steps are as follows:

[0037] (1) The Zr to be processed 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 The amorphous alloy samples were mechanically ground and polished, and ultrasonically cleaned with ethanol and deionized water for about 10 minutes at a temperature of 50-60°C, and then air-dried at room temperature.

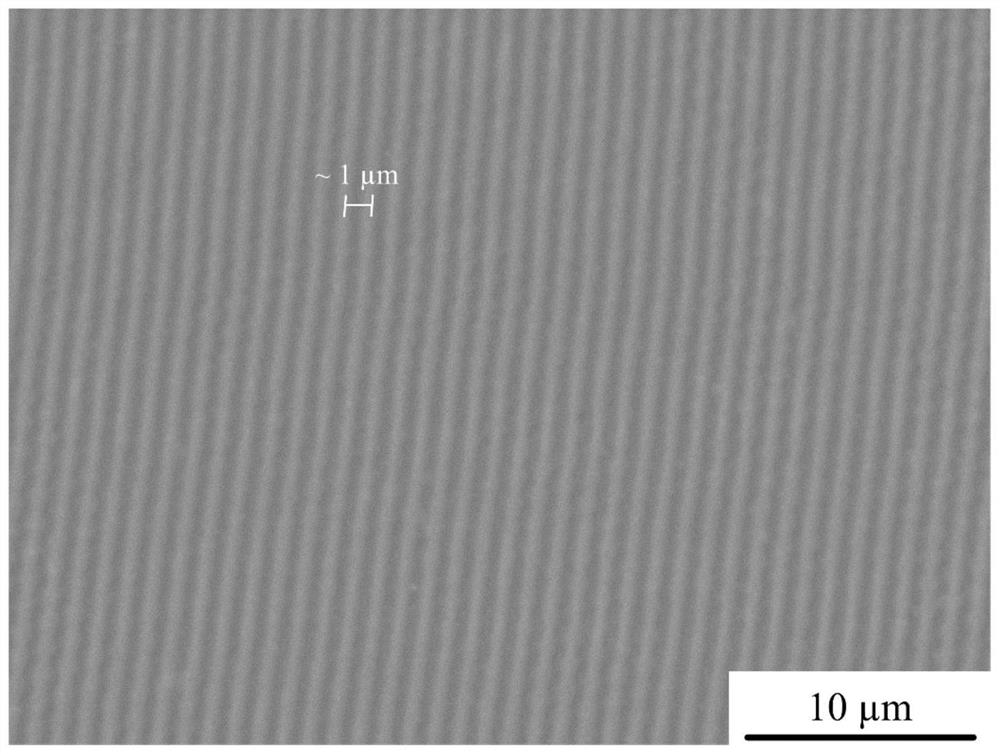

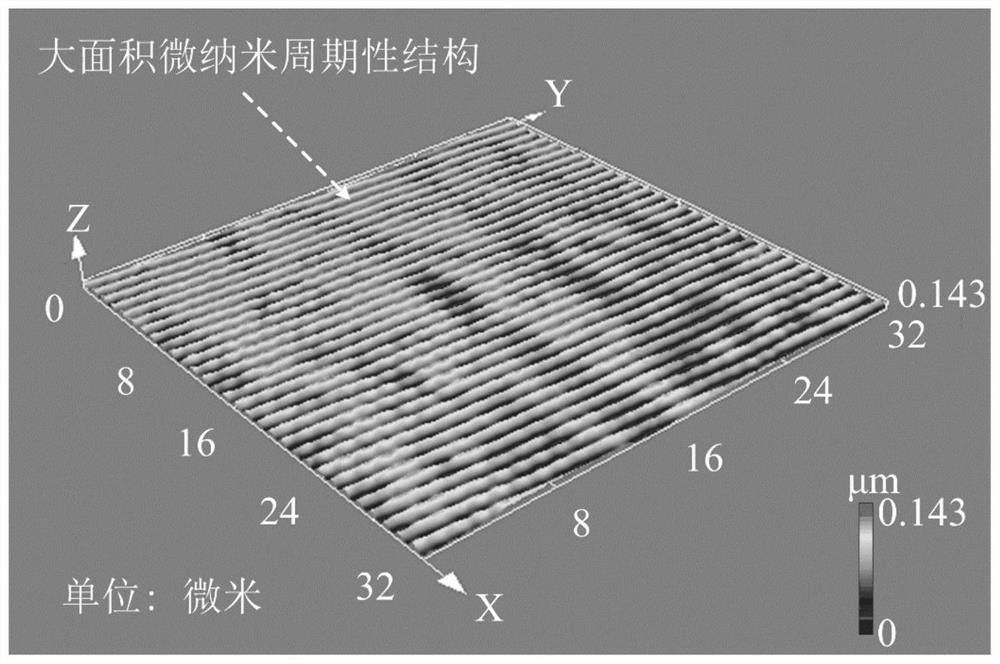

[0038] (2) Using argon as a protective gas, focus the laser beam on the surface of the amorphous alloy, set the laser irradiation parameters by the computer program, and draw straight lines with equal intervals in the computer software, the specific interval value is 6 μm, and then perform laser irradiation. Illuminated to form a large-area surface micro-nano periodic structure. The laser irradiation process parameters used are: argon pressure is 0.01MPa, laser wavelength is 1064nm, pu...

Embodiment 3

[0041] The method for preparing the micro-nano periodic structure on the surface of the amorphous alloy by nanosecond laser irradiation in this embodiment, the specific implementation steps are as follows:

[0042] (1) The Zr to be processed 41.2 Ti 13.8 Cu 12.5 Ni10 be 22.5 The amorphous alloy samples were mechanically ground and polished, and ultrasonically cleaned with ethanol and deionized water for about 10 minutes at a temperature of 50-60°C, and then air-dried at room temperature.

[0043] (2) Using argon as a protective gas, focus the laser beam on the surface of the amorphous alloy, set the laser irradiation parameters by the computer program, and draw a circular pattern with a diameter of 300 μm in the computer software, and then perform laser irradiation to form Circular micro-nano periodic structure. The laser irradiation process parameters used are: argon pressure is 0.01MPa, laser wavelength is 1064nm, pulse width is 7ns, repetition frequency is 600kHz, and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com