Waste mineral oil residue separating, processing and filtering device

A technology for oil residue separation and waste mineral oil, which is applied in the petroleum industry, only multi-stage series refining process treatment, hydrocarbon oil treatment, etc., can solve the problems of low efficiency and increased production cost, so as to improve processing efficiency and ensure cleanliness Sexuality and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0026] The components of the present invention are generally standard parts or components known to those skilled in the art, and their structures and principles are known for the skilled in the art or learned through a conventional experimental method.

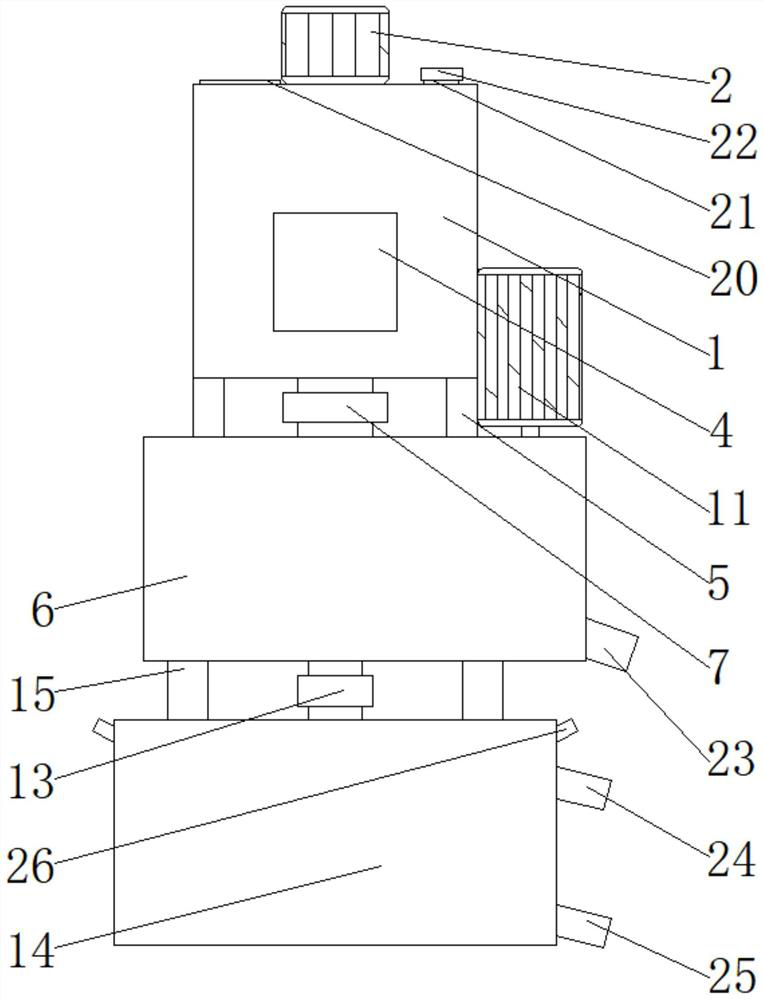

[0027] See Figure 1-4 , A waste mineral oil oil slag separation and processing filter, including a mixing tank 1, a feed port 19 at the top of the mix tank 1, and a cover plate 20 is connected to the right side of the feed port 19 through the hinge activity. The feed port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com