Extrusion and stretching composite forming method for conical cylinder with large height-diameter ratio

A composite forming and extrusion stretching technology, applied in the direction of metal extrusion dies, etc., can solve the problems of large number of die sets, low weld strength, low component performance, etc., to reduce production costs, improve mechanical properties, and shorten the manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

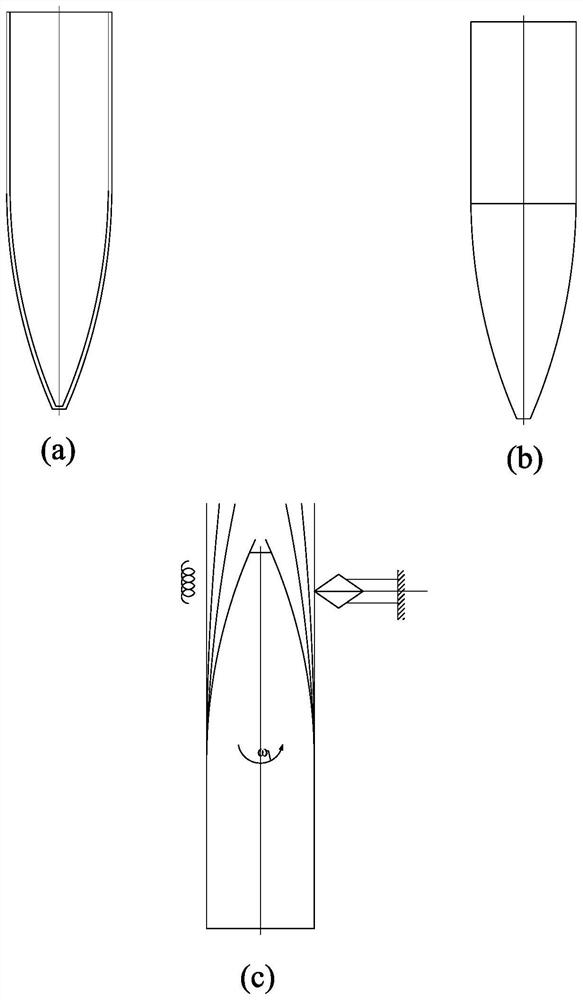

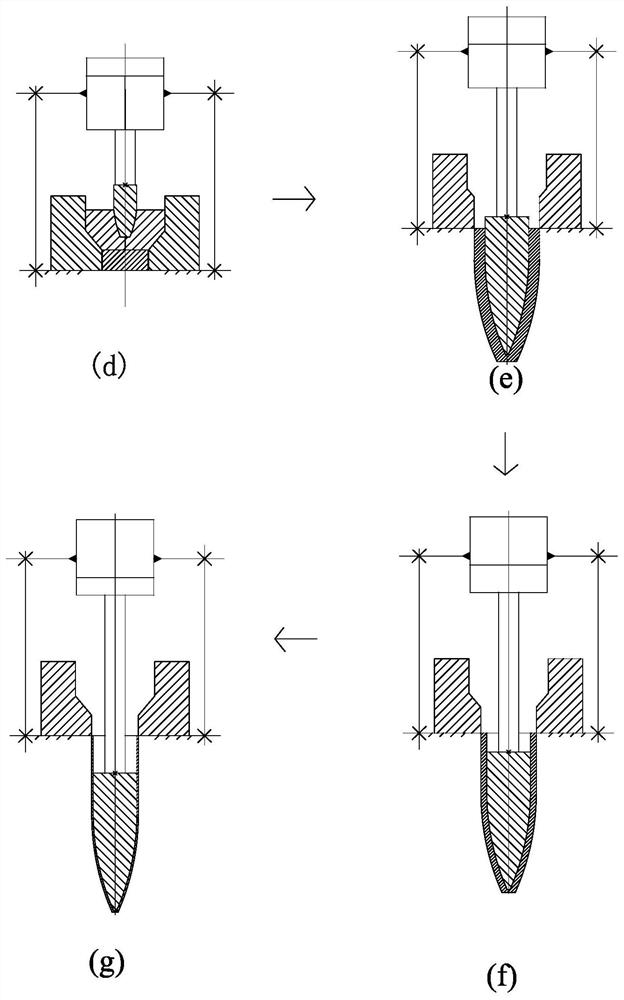

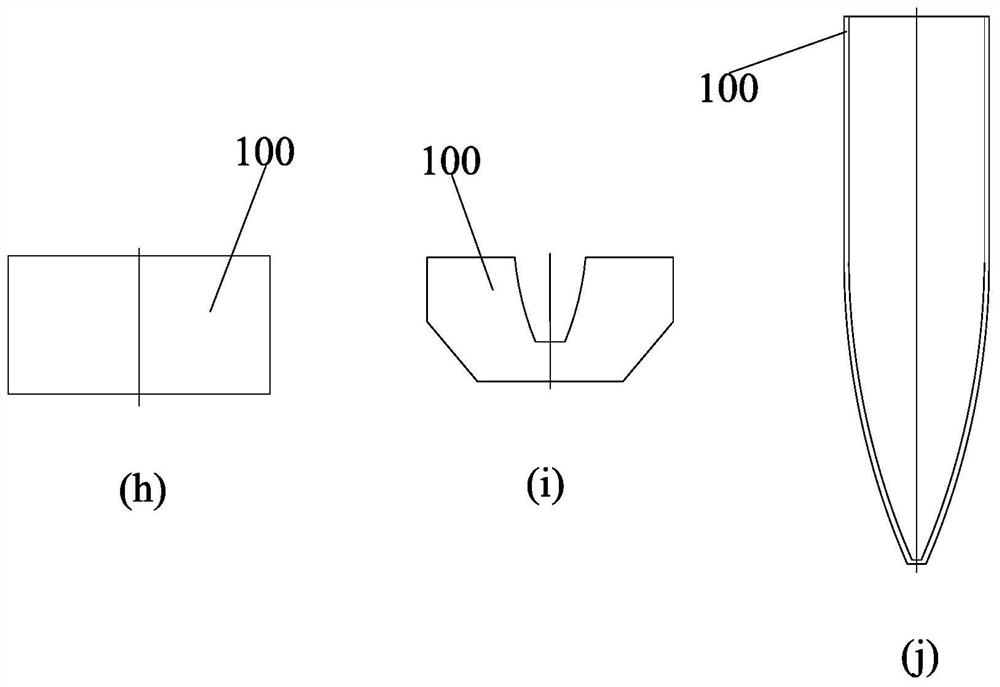

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as Figure 1-10 As shown, the present invention provides a extrusion-stretch composite forming method for a cone with a large aspect ratio, and relates to an extrusion-stretch composite forming device for forming a large cone. The forming device includes a die die 1, a central shaft Press cylinder 2, annular press cylinder 3, central axis plunger 4, annular plunger 5, mold punch 6 and annular pressure ring 7, the middle part of mold die 1 is a through forming channel 10, and the diameter of forming channel 10 is from top to The bottom is gradually gathered for the deformation of the blank. The central axis press cylinder 2 and the annular press cylinder 3 are coaxially arranged and respectively erected on the forming channel 10. The lower parts of the central axis press cylinder 2 and the annular press cylinder 3 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com