Ultraviolet ray-shielding agent composition absorbing radiation in uva range and preparation method therefor

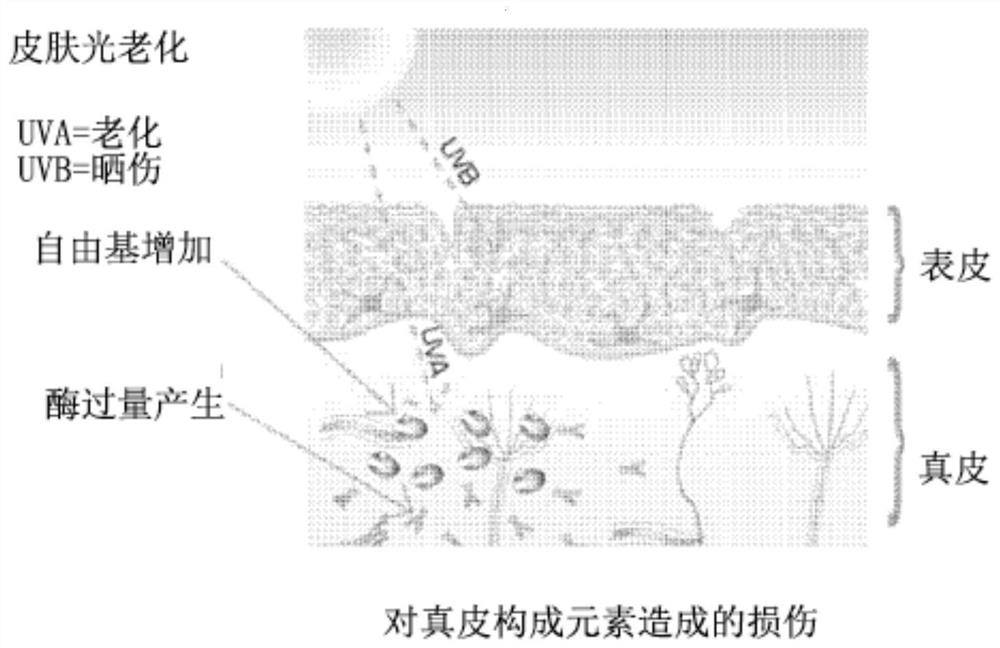

A technology for ultraviolet rays and shielding agents, which is applied in the field of preparation of ultraviolet shielding agent compositions, which can solve the problems of heavy powder texture, unsmooth application, and stiff feeling of use, etc., and achieve low light refractive index, prevent skin aging, and excellent spreadability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066]The second aspect of the present application provides a method for preparing cerium oxide particles for ultraviolet shielding that absorbs light in the UVA band, which includes the following steps: preparing particles selected from cerium hydroxide, cerium oxide, and cerium carbonate. (cerium carbonate), cerium nitrate (cerium nitrate), cerium chloride (cerium chloride), ammonium cerium nitrate (ammonium cerium nitrate), and combinations thereof; cerium precursor species; adding quaternary ammonium species to said cerium precursor species ; and reacting the mixture added with the ammonium species to obtain cerium oxide (CeO 2 )particle.

[0067] The detailed description of the part that overlaps with the first aspect of the present application is omitted, but even if the description is omitted, the description of the first aspect of the present application can also be applied to the second aspect.

[0068] Hereinafter, the preparation method of the cerium oxide particle...

preparation example

[0089] Preparation Example: Preparation of a dispersion of water-dispersed cerium oxide particles

[0090] To prepare the ultraviolet screener composition of the present invention, cerium oxide particles are prepared.

[0091] Step 1: Preparation of Cerium Oxide Particles

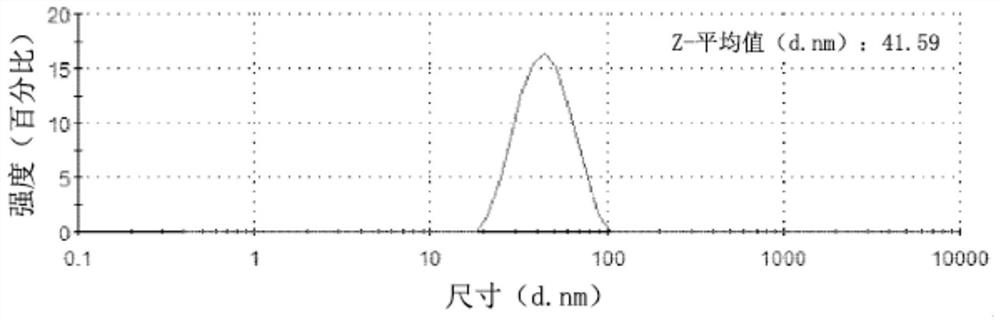

[0092] For cerium nitrate, which is a precursor of cerium oxide, particles are grown by a bottom-up chemical synthesis method, that is, a hydrothermal reaction. Mix and stir 100 parts by weight of the cerium nitrate and 500 parts by weight of deionized water (based on 100 parts by weight of cerium nitrate), and add 200 parts by weight of ammonia water to prepare a precursor solution with a pH value of 10. The precursor solution was put into a hydrothermal synthesizer and reacted at 180° C. for 24 hours to prepare cerium oxide particles. The particles were centrifuged to remove unreacted substances. The primary particle diameter of the cerium oxide particles from which the unreacted substances were re...

experiment example 1

[0107] Experimental Example 1: Analysis of the wavelength region of the absorbed light (ultraviolet-visible spectrophotometry, UV-Vis spectrophotometry)

[0108] The wavelength of light absorbed by the dispersion of water-dispersed cerium oxide particles prepared in the above Preparation Example and the dispersion containing conventional cerium oxide particles of Comparative Example 1 by UV-Vis spectrophotometry area was analyzed and the results are shown in Figure 4 middle.

[0109] like Figure 4 As shown in , it can be confirmed that the dispersion liquid containing conventional cerium oxide particles of Comparative Example 1 absorbs light in the wavelength range of about 270 nm to 320 nm, on the contrary, the dispersion liquid of water-dispersed cerium oxide particles prepared in the preparation example of the present invention Light in the wavelength range of about 320nm to 400nm is absorbed. Therefore, it can be confirmed that the dispersion liquid of the water-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com