Sunscreen composition comprising surface-defected cerium oxide particles, and preparation method therefor

A technology of shielding agent and ultraviolet rays, which is applied in the field of preparation of ultraviolet shielding agent compositions, which can solve the problems of heavy powder texture, unsmooth application, stiff feeling of use, etc., and achieve low light refractive index, excellent spreadability, and high ultraviolet protection index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

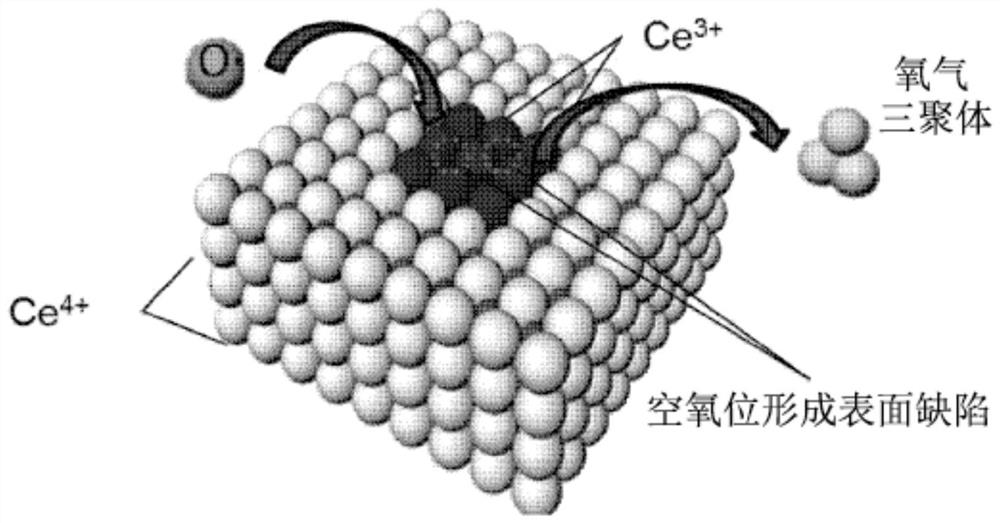

[0086] The second embodiment of the present application provides a preparation method of an ultraviolet shielding agent composition, which includes the following steps: (cerium nitrate), cerium chloride (cerium chloride), cerium ammonium nitrate (ammoniumcerium nitrate) and their combinations, undergo hydrothermal synthesis to obtain cerium oxide (CeO 2 ) particles; and adding a metal oxide solution to the obtained cerium oxide (CeO 2 ) particles and perform hydrothermal synthesis to prepare Ce containing 3 + Ceria particles with surface defects.

[0087] Detailed descriptions are omitted for parts that overlap with the first embodiment of the present application. Even if the description is omitted, the content described in the first embodiment of the present application can also be applied to the second embodiment.

[0088] Hereinafter, the manufacturing method of the ultraviolet shielding agent composition of 2nd Embodiment of this application is demonstrated in detail. ...

Embodiment

[0106] Example: Preparation of Cerium Oxide Dispersion Containing Cerium Oxide Particles with Surface Defects

[0107] Step 1: Preparation of Ceria Particles with Surface Defects

[0108] For cerium nitrate, which is a precursor of cerium oxide, particles are grown by a bottom-up chemical synthesis method, that is, a hydrothermal reaction. Add 100 parts by weight of cerium oxide and 1 part by weight of aluminum nitrate (based on 100 parts by weight of cerium oxide) to 500 parts by weight of deionized water, stir, and add 200 parts by weight of ammonia water to prepare a pH value of 10 precursor solution. The precursor solution was put into a hydrothermal synthesizer and reacted at 180° C. for 24 hours, thereby preparing cerium oxide particles with surface defects through alumina. The particles were centrifuged to remove unreacted substances. In the cerium oxide containing alumina from which the unreacted substances were removed, 0.01% of alumina was contained with respe...

experiment example 1

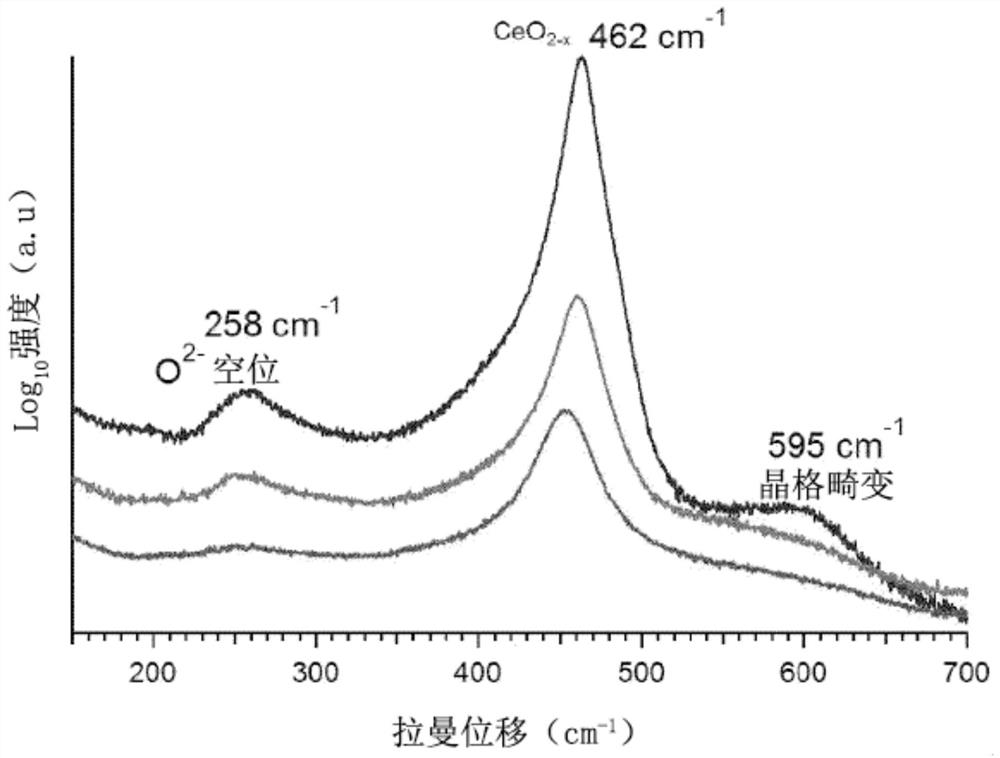

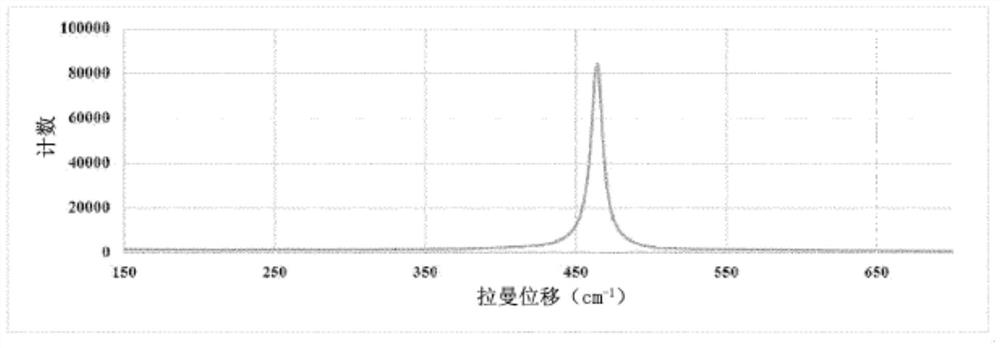

[0113] Experimental Example 1: Raman Analysis of Cerium Oxide Particles for Confirmation of Surface Defects

[0114] Raman analysis is carried out on the cerium oxide particles contained in the cerium oxide dispersion liquid of the comparative example and the embodiment, and are shown in respectively Figure 3a and 3b . can be confirmed as Figure 3a As shown, the cerium oxide particles without surface defects are at about 460cm -1 A peak was detected at , but as Figure 3b As shown, the cerium oxide particles with surface defects are at about 595cm -1 peaks were detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com