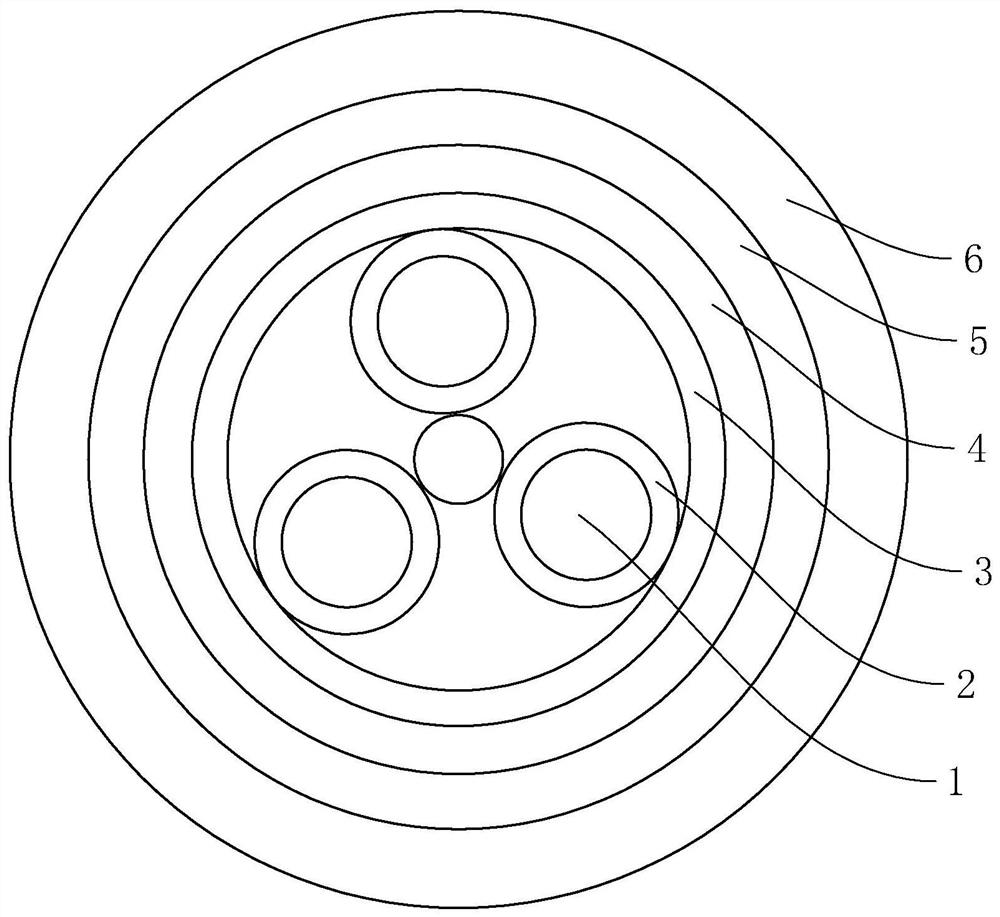

Water-blocking powder for waterproof cable, preparation method of water-blocking powder and waterproof cable

A technology of waterproof cable and water-blocking powder, which is used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problem that polyacrylic resin cannot play a good role in blocking swelling, poor salt resistance, and poor waterproof performance of waterproof cables. To achieve good waterproof effect, improve waterproof performance, and reduce the length of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0051] A purified lignozoulfonate, which is prepared according to the following method:

[0052] (1) Sodium lignin sulfate is added to the pecker water and mix, formulated into a concentration of 6 wt% lignozo sulfonate mixture;

[0053] (2) Transfer of sodium lignozoulfonate to the UF201 ultrafiltration machine (Wuxi Pujing Technology Development Co., Ltd.), filtering with ultrafiltration membranes with a total number of molecular weights of 10,000, the working pressure is 0.142MPa, The ultrafiltration of the cycle is ultrafiltrated into the ultrafiltration membrane microporous is a colorless transparent solution. This solution is a sodium lignozo sulfonate solution. The number average molecular weight of sodium ligno sulfonate in the solution is 10000, and after drying Purified lignozoulfonate.

preparation example 2

[0055] A differential point of the purified lignozoulfonate, and the preparation of Example 1 is that the interceptor number average molecular weight of the ultrafiltration membrane in step (2) is 3000.

preparation example 3

[0057] A differential point of the purified lignozoulfonate, and the preparation of Example 1 is that the interceptor number of ultrafiltration membranes in step (2) is 4000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com