Amphoteric crosslinked polymer coil and preparation method thereof

A cross-linked polymer and amphoteric technology, which is applied in drilling compositions, chemical instruments and methods, earth square drilling and production, etc., can solve the problems that are difficult to meet the requirements, achieve good salt resistance, and improve oil recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 Preparation of amphoteric cross-linked polymer coils

[0068] Add 5.45 grams of 2-acrylamide-2-methylpropanesulfonic acid, 14.67 grams of acrylamide, and 6.24 grams of acryloyloxyethyl trimethyl chloride to 10°C and 15 grams of ultrapure water (conductivity ≤ 4 μS / cm). Ammonium chloride, 0.56 g of N,N'-diallyl-N,N,N',N'-tetramethylhexammonium chloride, 0.63 mg of chelating agent disodium edetate and 0.5 mg of co-solvent Urea, stir evenly, adjust the pH value of the solution with 35% sodium hydroxide to 4.0 to 5.0, and obtain an aqueous phase solution in which polymerized monomers are dissolved;

[0069] Add 3.12 grams of sorbitan trioleate, 2.88 grams of sorbitan monooleate and 39.02 grams of 3# white oil into a jacketed reactor equipped with a gas inlet tube, a thermometer and a constant speed stirrer, stir and mix well A white oil solution with dispersant was obtained.

[0070] At 5°C, with a stirring speed of 1000 rpm, slowly add the obtained aqueous p...

Embodiment 2

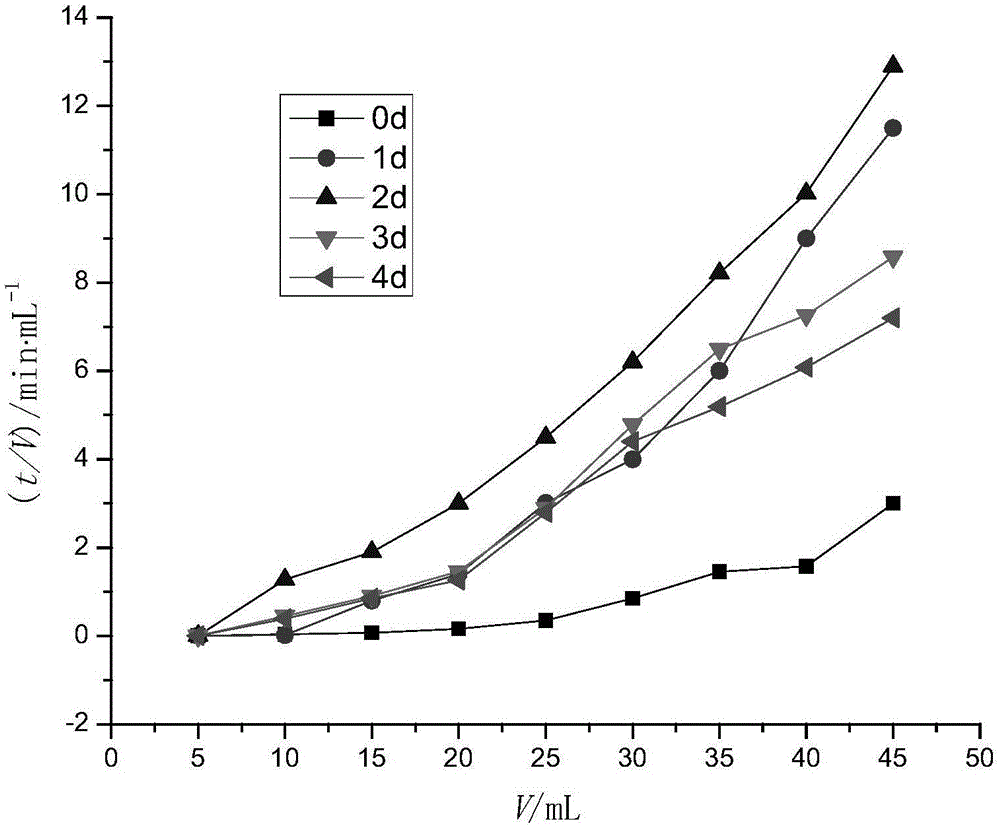

[0072] Embodiment 2 Determination of amphoteric cross-linked polymer coil salt resistance

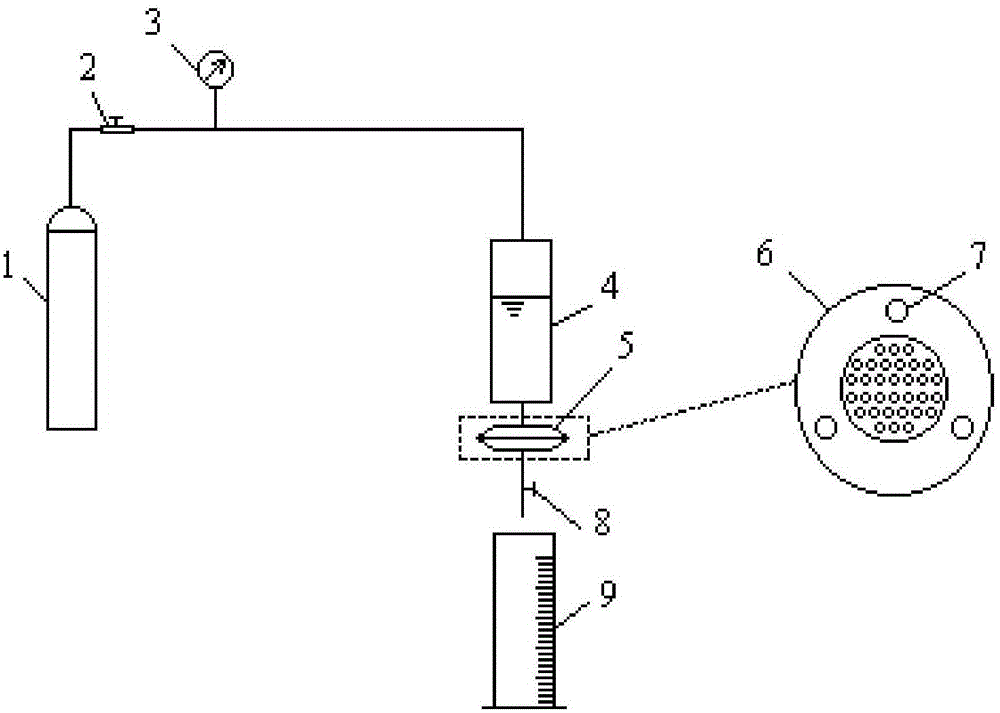

[0073] The amphoteric crosslinked polymer coil powder prepared in Example 1 with a mass fraction of 300 mg / kg was matured at room temperature for 0 days, 1 day, 2 days, 3 days, 4 days, the aqueous solution of amphoteric crosslinked polymer coils was obtained. The method of low-pressure differential microporous membrane was used to measure the plugging of amphoteric cross-linked polymer coil aqueous solution. Experimental device see figure 1 , the device includes a nitrogen cylinder 1, a pressure reducing valve 2, a pressure gauge 3, a cylinder body 4, a flange 5, a valve 8 and a measuring cylinder 9, wherein the flange 5 includes a lower flange 6, and the lower flange 6 has bolts Connection 7.

[0074] The experimental operation steps are as follows:

[0075] (1) Soak the mixed cellulose ester hot press filter membrane with deionized water for 3 days;

[0076] (2) Place the micropo...

Embodiment 3

[0078] Embodiment 3, the profile control property of amphoteric cross-linked polymer coil

[0079] Gained water-swellable amphoteric cross-linked polymer coil (SS 20 ) powder was matured in simulated water of SZ36-1 oilfield at 65°C for 48 hours, and prepared into an aqueous solution of amphoteric cross-linked polymer coils with a mass fraction of 400 mg / kg. 2.0μm 2 The single-tube artificial core was used to carry out the displacement experiment of simulated oil in Bohai SZ36-1 oilfield, and it was measured that the amphoteric cross-linked polymer coil aqueous solution obtained under the experimental conditions increased the simulated oil recovery by 18.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com