Magnetic injection increase and depressurization test system

A test system and magnetic treatment technology, applied in the field of magnetic treatment, can solve the problems of no indoor research and achieve the effect of enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

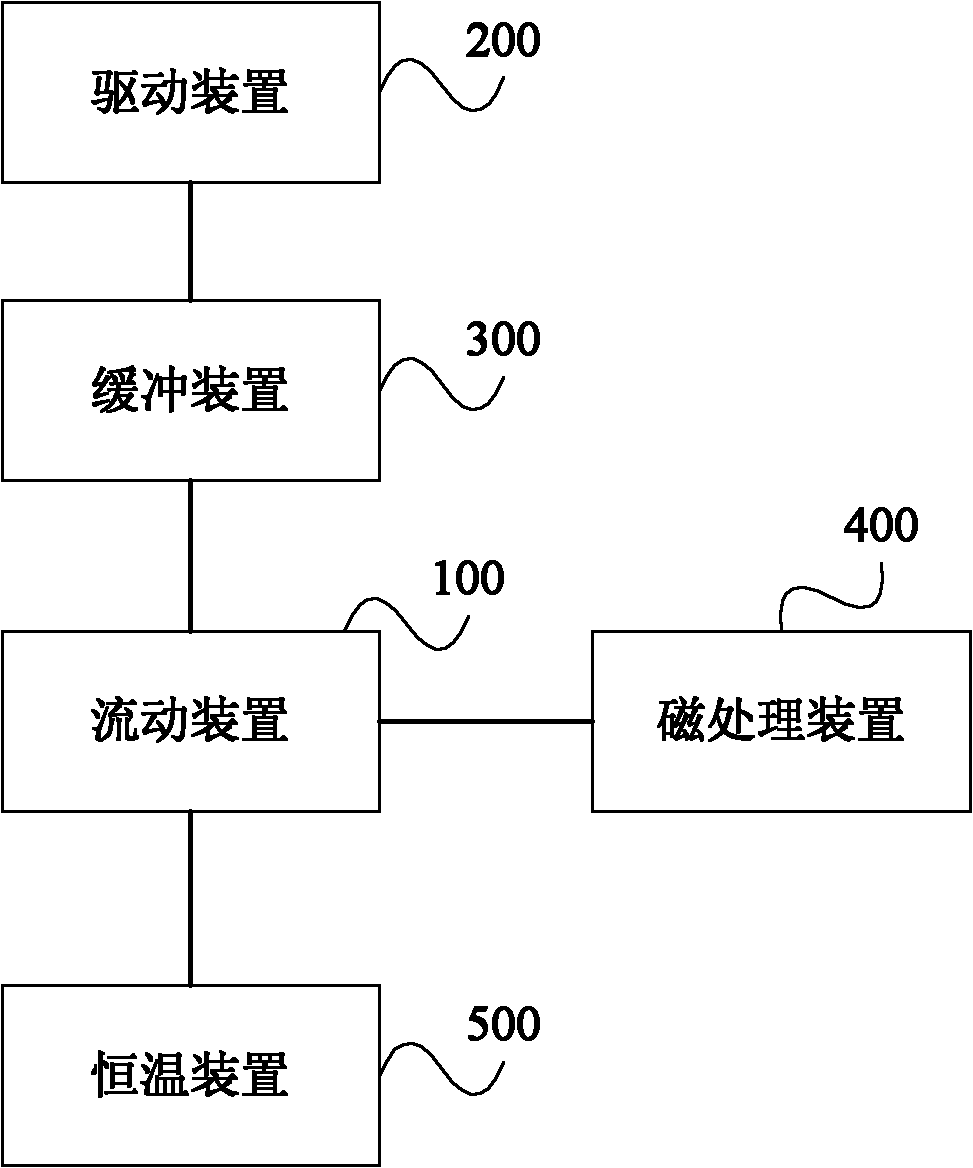

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Constant flow displacement.

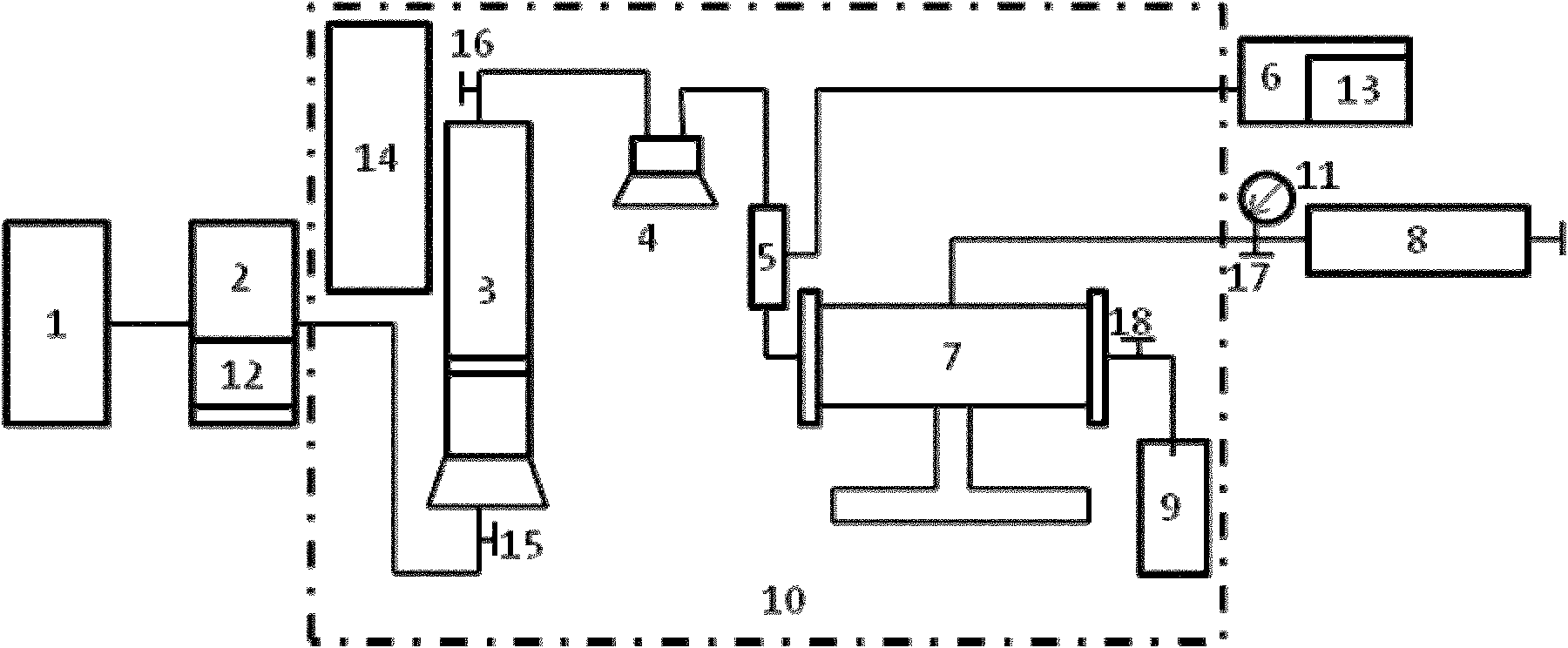

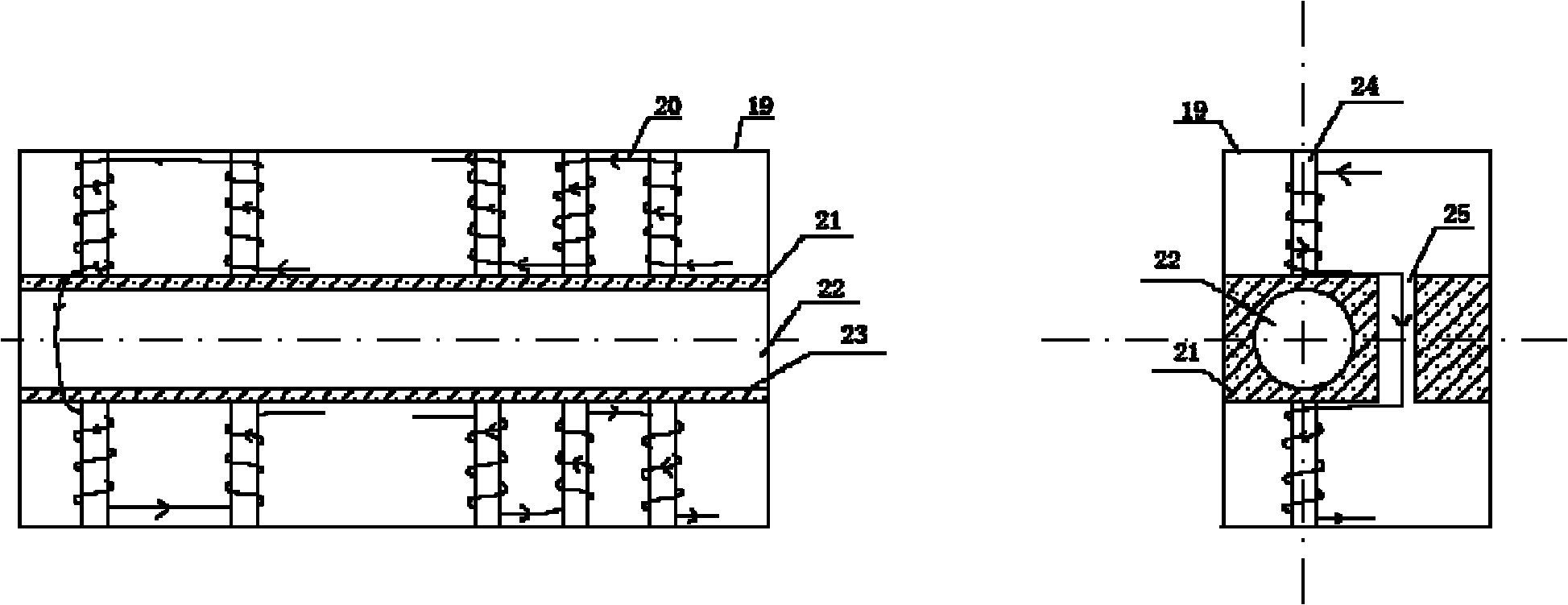

[0028]Air compressor 1, pump 2, intermediate container 3, six-way valve 4, core holder 7, and test tube 9 are connected in sequence, and when the six-way valve 4 is connected to the core holder 7, the pipeline passes through the magnetic processor 5 , the transformer 6 is connected to the power supply, connected to the magnetic processor 5, the ring pressure valve 8 is connected to the core holder 7 to provide ring pressure for the test core, and the vacuum gauge 11 is connected to the ring pressure valve 8 to display the ring pressure value. Wherein the intermediate container 3, the six-way valve 4, the magnetic processor 5, the rock core holder 7, and the test tube 9 are all placed in the thermostat 10.

[0029] Put the test rock core into the core holder 7, place the test displacement water in the intermediate container 3, use the back pressure valve 8 to add ring pressure to the rock core, adjust the transformer 6, select ...

Embodiment 2

[0030] Embodiment 2: constant pressure displacement.

[0031] Air compressor 1, pump 2, intermediate container 3, six-way valve 4, core holder 7, and test tube 9 are connected in sequence, and when the six-way valve 4 is connected to the core holder 7, the pipeline passes through the magnetic processor 5 , the transformer 6 is connected to the power supply, connected to the magnetic processor 5, the ring pressure valve 8 is connected to the core holder 7 to provide ring pressure for the test core, and the vacuum gauge 11 is connected to the ring pressure pump 8 to display the ring pressure value. Wherein the intermediate container 3, the six-way valve 4, the magnetic processor 5, the rock core holder 7, and the test tube 9 are all placed in the thermostat 10.

[0032] Put the test rock core into the rock core holder 7, place the test displacement water in the intermediate container 3, use the ring pressure valve 8 to add ring pressure to the test rock core, adjust the transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com