Condensate oil foam discharging agent applied to natural gas extraction

A technology of foam unloading agent and condensate oil, which is applied in the field of foam stabilizer, can solve the problems of reduced foaming ability and stability of foam unloading agent, and achieves the effects of good foam stability, strong foaming ability and reduced slip loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Condensate oil foaming agent suitable for natural gas exploitation, the weight percentage of each component is: sodium petroleum sulfonate, 20%; 2-undecyl-N-hydroxyethyl-N-carboxymethyl imidazoline, 20% ; dodecyl sultaine fluorocarbon surfactant, 2%; nonionic polyacrylamide (8 million), 0.2%; water, 52.8%.

[0030] Preparation:

[0031] (1) At normal temperature and pressure, add 50% of the total weight of water to the reactor, then add foam stabilizer, non-ionic polyacrylamide, molecular weight 8 million, stir for 0.5 to 1 hour, then add the remaining 50% of water, Stir until uniform;

[0032] (2) Sodium petroleum sulfonate (anionic surfactant), 2-dodecyl-N-hydroxyethyl-N-carboxymethyl imidazoline (ampphoteric surfactant), dodecyl sulfobetaine Fluorocarbon (fluorocarbon surfactant) is added to the reaction kettle and fully stirred for 1 to 2 hours; a condensate oil foaming agent suitable for natural gas exploitation is obtained.

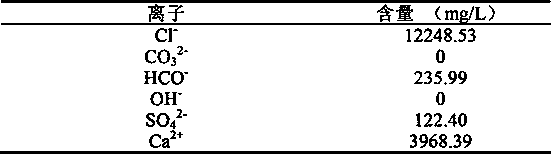

[0033] Composition of water contai...

Embodiment 2

[0037] Embodiment 2: the condensate oil foaming agent that is applicable to natural gas exploitation, each component weight percent is:

[0038]

[0039] Foaming agent preparation steps: the same as in Example 1.

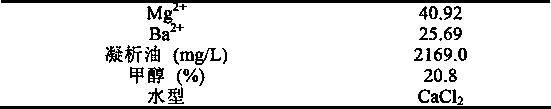

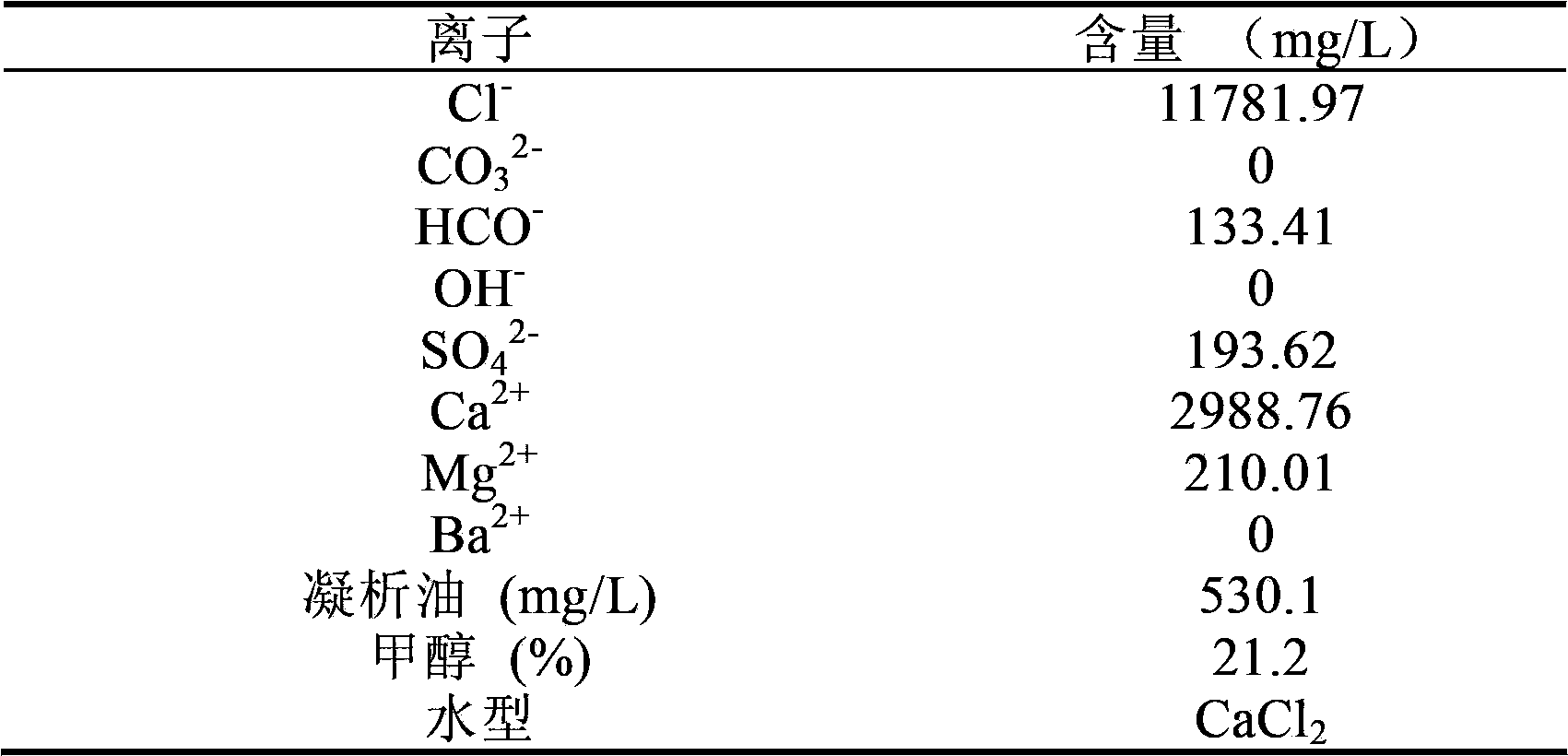

[0040] Composition of water containing condensate:

[0041]

[0042] Pai Pai effect:

[0043]

Embodiment 3

[0044] Embodiment 3: the condensate oil foaming agent that is applicable to natural gas exploitation, each component weight percent is:

[0045]

[0046] Foaming agent preparation steps: the same as in Example 1.

[0047] Composition of water containing condensate:

[0048]

[0049] Pai Pai effect:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com