Production process for increasing whiteness of titanium dioxide

A production process and technology of titanium dioxide, applied in the direction of titanium compounds, titanium dioxide, titanium oxide/hydroxide, etc., can solve problems affecting production efficiency, affecting product whiteness, troublesome solution filtration, etc., to improve processing quality and cooling efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] see Figure 1-4 , the present embodiment discloses a production process for increasing the whiteness of titanium dioxide, comprising the steps of:

[0035] S1. Raw material processing: put ilmenite into the pulverizer for pulverization, after pulverization, it will be coarsely and finely separated by air separator, and the unqualified fineness will be returned to the pulverizer for reprocessing, and the qualified powder will be transported to the silo to store;

[0036] S2. Acid hydrolysis treatment: add the powder prepared in step S1 into the acid hydrolysis tank, then add sulfuric acid with a concentration of 91%-95% into the acid hydrolysis tank, stir evenly, and then pass into the acid hydrolysis tank Steam, under the action of steam, the material undergoes an acidolysis reaction. After the acidolysis reaction, let it stand for a period of time, then add water to the acidolysis tank, and use the water to extract the material. After the extraction is completed, the ...

Embodiment 2

[0041] This embodiment discloses a device for increasing the whiteness of titanium dioxide in the production process, including a housing 1 and a liquid storage tank 2, the housing 1 is cylindrical, the liquid storage tank 2 is located on the lower side of the housing 1, and the liquid storage tank 2 A circulation pump 3 is provided inside, a liquid outlet pipe 4 is provided at the upper end of the liquid storage tank 2, and the bottom end of the liquid outlet pipe 4 communicates with the liquid outlet of the circulation pump 3;

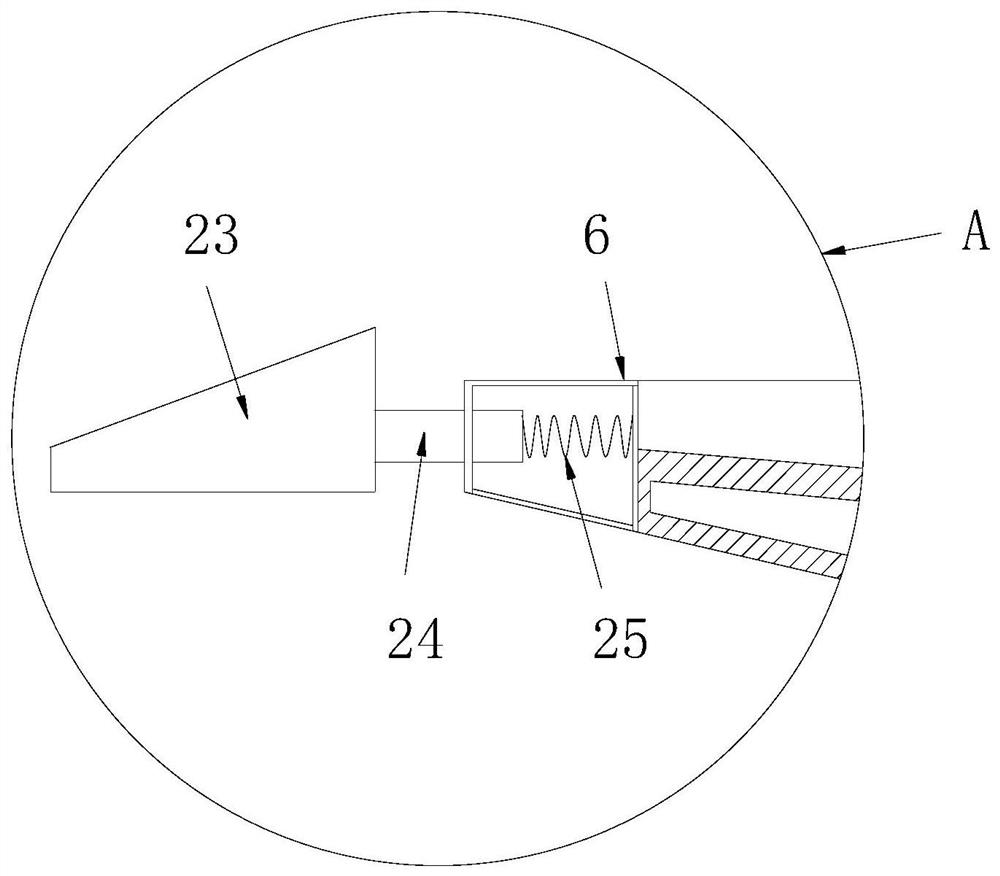

[0042] Several circulating cooling assemblies are provided on the liquid outlet pipe 4, and the circulating cooling assembly includes a first processing disk 5 and a second processing disk 6, the first processing disk 5 and the second processing disk 6 are all in the shape of a cone, and the first processing disk The disk 5 and the second processing disk 6 are arranged as mirror images of each other, the outside of the first processing disk 5 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com