A kind of biological type zero-valent iron sulfide material and its preparation method and application

A zero-valent iron and bio-based technology, applied in biochemical equipment and methods, microbial-based methods, chemical instruments and methods, etc., can solve the problems of reduced mobility and reactivity, and limitations on the large-scale application of zero-valent iron technology , to achieve long-lasting repair of heavy metal pollution, good dispersion and chemical stability, and high interface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

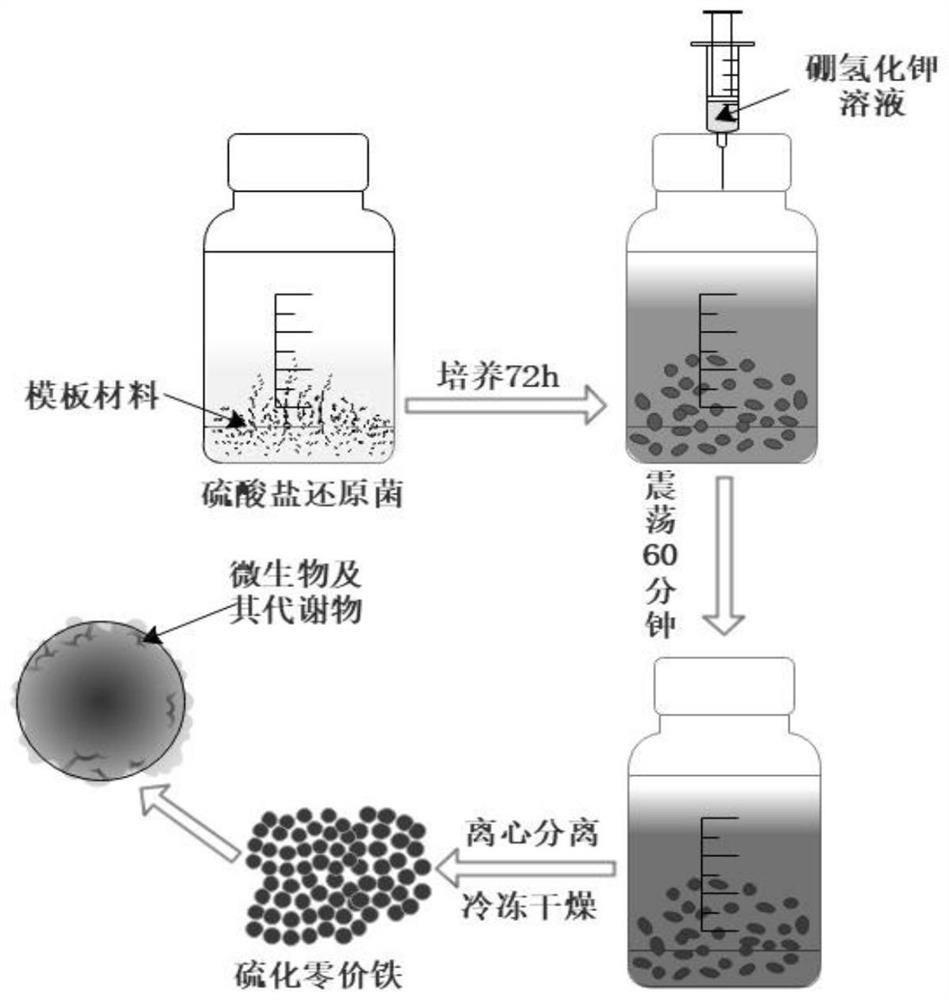

[0024] The invention provides a preparation method of biological type zero-valent iron sulfide material, comprising the following steps:

[0025] adding the template material into the culture medium for sulfate-reducing bacteria, and performing anaerobic sterilization to obtain a sterilized culture solution;

[0026] After mixing the sterilized culture solution and ferrous salt, inoculate sulfate-reducing bacteria, and perform microbial reduction in an anaerobic environment to obtain microbial reduction;

[0027] Under an inert gas atmosphere, the microbial reduction product is mixed with a reducing agent to carry out a chemical reduction reaction to obtain the biological zero-valent iron sulfide material.

[0028] In the invention, the template material is added into the culture medium of sulfate-reducing bacteria, anaerobically sterilized, and the sterilized culture solution is obtained.

[0029] In the present invention, the template material preferably includes one or mor...

Embodiment 1

[0063] figure 1 It is a schematic diagram of the process flow for preparing bio-type zero-valent iron sulfide material in Example 1 of the present invention.

[0064] A biological type zero-valent iron sulfide material, the specific preparation method is as follows:

[0065] (1) Prepare improved Baar's medium, the formula is as follows: KH 2 PO 4 0.5 g / L, NH 4 Cl 1g / L, CaSO 4 2H 2 O1g / L, MgSO 4 2 g / L, sodium citrate 5g / L, sodium lactate 3.5g / L, yeast extract 1g / L; adjust the pH value to 7.5; add kaolin to control the liquid-solid ratio to 100:1; fill the above solution to anaerobic In the bottle, sterilize at 121°C for 15 minutes; after the anaerobic bottle is cooled, add Fe(NH 4 ) 2 ·(SO 4 ) 2 ·6H 2 O to 2g / L, and inoculate sulfate-reducing bacteria in an anaerobic incubator with an initial bacterial concentration of 5×10 7 CFU / mL; seal to ensure an anaerobic environment in the anaerobic bottle, and place it in a constant temperature shaker for cultivation at 30°C...

Embodiment 2

[0070] A biological type zero-valent iron sulfide material, the specific preparation method is as follows:

[0071] (1) Prepare improved Baar's medium, the formulation of improved Baar's medium is the same as in Example 1; adjust the pH value to 7.5; add kaolin to control the liquid-solid ratio to 100:0.5; put the above solution in an anaerobic bottle at 121°C sterilized for 15 minutes; after the anaerobic bottle cools down, add Fe(NH 4 ) 2 ·(SO 4 ) 2 ·6H 2 O to 3g / L, and inoculate sulfate-reducing bacteria in an anaerobic incubator with an initial bacterial concentration of 1×10 7 CFU / mL; seal to ensure an anaerobic environment in the anaerobic bottle, and place it in a constant temperature shaker for cultivation at 30°C;

[0072] (2) Potassium borohydride solution is prepared, and the molar concentration of potassium borohydride is 1mol / L;

[0073](3) After the microorganisms in step (1) are cultivated for 72h, under the protection of nitrogen atmosphere, slowly add th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com