Aldehyde hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of hydrogenation preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of small pore size, low hydrogenation activity, etc., to reduce the pressure drop of the bed and reduce the energy consumption of the device operation , Improve the effect of internal diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of aldehyde hydrogenation catalyst, comprises the steps:

[0031] Step 1, dissolving copper precursor, zinc precursor, aluminum precursor and pore expander in water to form a mixed solution, and then co-precipitating the mixed solution with a precipitant;

[0032] Step 2, aging the co-precipitated mixture obtained in step 1, filtering to obtain a filter cake, drying the filter cake and mixing it with an auxiliary agent evenly to obtain a powder;

[0033] Step 3, mixing the powder with a binder and performing pre-granulation to obtain a pre-granulated catalyst;

[0034] Step 4, calcining the pre-granulated catalyst, and then adding graphite into a tablet to obtain an aldehyde hydrogenation catalyst.

[0035] Wherein, the copper precursor is preferably a soluble salt of copper, the zinc precursor is preferably a soluble salt of zinc, and the aluminum precursor is preferably a soluble salt of aluminum, such as copper nit...

Embodiment 1

[0047] (1) Dissolve 20g of P123 in 1200ml of water, then add 123g of copper nitrate, 185g of zinc nitrate, and 7g of aluminum nitrate to form 1300ml of a mixed solution of copper, zinc, and aluminum. Carry out co-precipitation, control the precipitation temperature at about 50°C, the pH value during the process is 6.8-7.5, the neutralization time is 30 minutes, and the final pH value is 7.0-7.2;

[0048] (2) Stir and age the mixed solution at 50° C. to 60° C. for 30 minutes, wash with deionized water at 40° C. to 50° C. for four times, and filter to obtain a filter cake for drying. Mix the filter cake obtained by drying with 10 g of amorphous silicon evenly to obtain a powder;

[0049] (3) Add 0.3g of sodium hydroxymethylcellulose and 1.2g of silica sol into 2g of water, fully stir to make a binder; mix the binder with the powder, and pre-granulate;

[0050] (4) The pre-granulated catalyst precursor was calcined at 360-550° C., and then 2% of the total mass of the obtained ma...

Embodiment 2

[0052] (1) Get 25g water-soluble chitosan and dissolve in 1200ml water, then add 123g copper nitrate, 175g zinc nitrate, 14g aluminum nitrate to make copper, zinc, aluminum mixed solution 1300ml, in the precipitation tank with stirring Co-precipitate with sodium carbonate solution, control the precipitation temperature at about 50°C, the pH value during the process is 6.8-7.5, the neutralization time is 30 minutes, and the final pH value is 7.0-7.2;

[0053] (2) Stir the mixed solution at 50°C to 60°C, age for 30min, wash with deionized water at 40°C to 50°C four times, filter and dry the filter cake; mix the dried filter cake with 10g of amorphous silicon evenly , to obtain powder;

[0054] (3) Add 0.3g sodium hydroxymethyl cellulose and 1.2g silica sol into 2g of water, fully stir to make a binder; the obtained filter cake is mixed with the binder, and pre-granulated;

[0055] (4) The pre-granulated catalyst precursor was calcined at 360-400° C., and then 2% of the total ma...

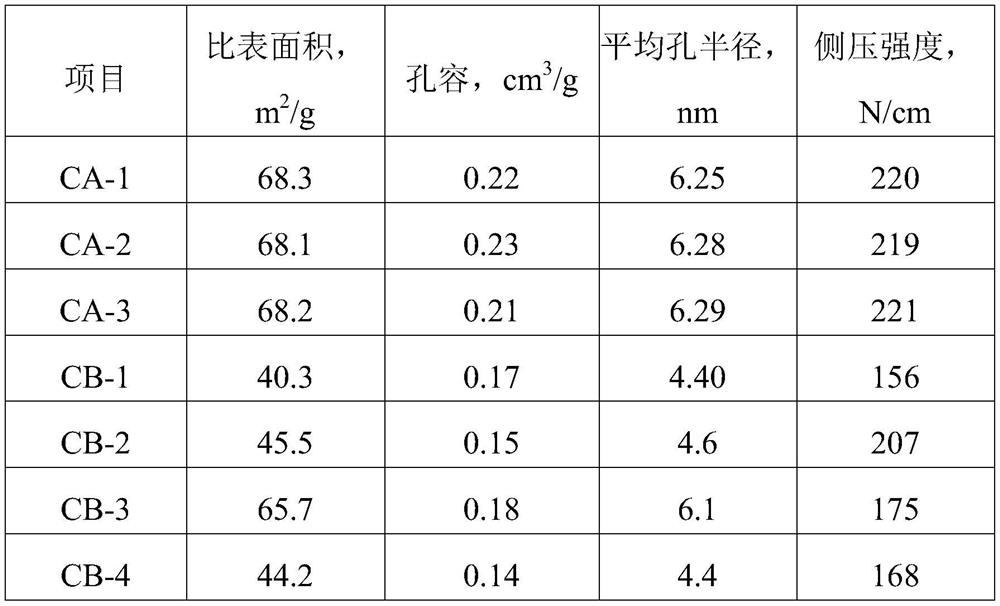

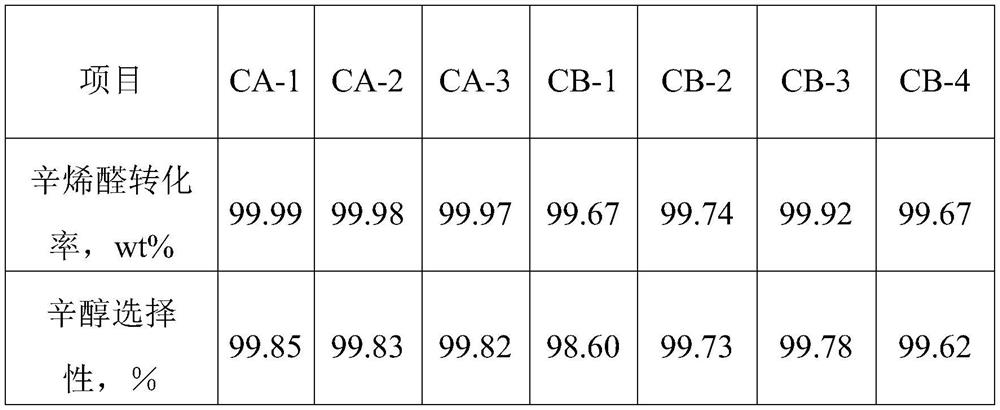

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com