Method for absorbing and separating ammonia-containing gas by using supergravity enhanced ionic liquid

An ionic liquid and ammonia-containing gas technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory separation of ammonia-containing gas, and achieve improved gas-liquid mixing effect, stable operation, and residence time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

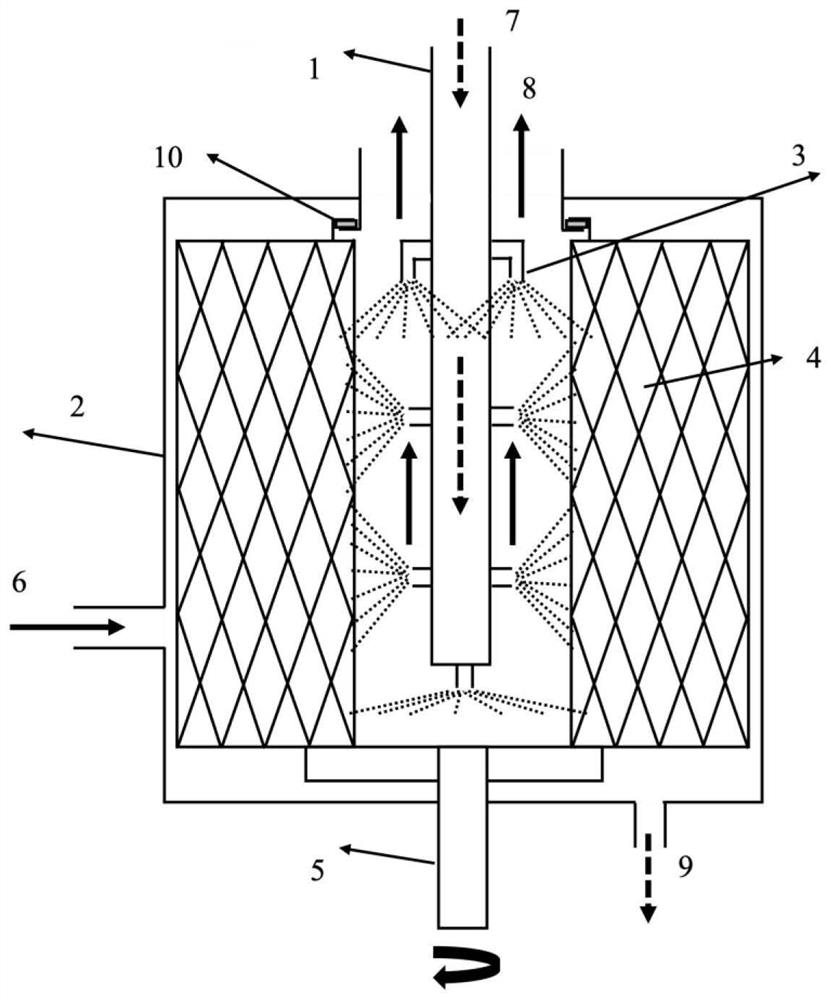

Embodiment 1

[0019] The ammonia concentration in the imported gas composition is 0.5%, and the gas pressure is 1.5atm. The ionic liquid used for absorption is proton type ionic liquid 1-butylimidazole bistrifluoromethanesulfonimide salt ([Bim][NTf 2 ]). The inner packing of the rotor of the spraying rotary packed bed is stainless steel wire mesh packing, and the rotating speed of the rotor is adjusted to 3000 rpm. The ionic liquid at a temperature of 30°C is sprayed into the packing of the rotating packed bed through a liquid sprayer. The quantity of the liquid distribution atomizer is 1, and the pipe diameter is 20mm. The atomizer is equipped with 4 layers of solid conical nozzles, and 6 nozzles are evenly distributed in the upper single layer. The gas-liquid ratio used is 200:1, and the gas-liquid contacts in countercurrent in the reactor. Ammonia removal efficiency reaches 90%. The absorbed ionic liquid was desorbed at 91°C and 10kPa and reused.

Embodiment 2

[0021] The ammonia concentration in the imported gas composition is 5%, and the gas pressure is 13 atm. The absorbent is a compound solution of hydroxyl-type ionic liquid 1-(2-hydroxyethyl)-3-methylimidazolium dicyanamide ([EtOHmim][DCA]) and ethylene glycol in a mass ratio of 7:3. The rotor speed is 2850 rpm. The temperature of the absorbent is 20°C, the number of atomizers is 8, the pipe diameter is 10mm, and 3 layers of solid conical nozzles are installed, and 6 nozzles are evenly distributed in the upper single layer. The gas-liquid ratio used is 50:1, and the gas-liquid contacts in countercurrent in the reactor. Ammonia gas removal efficiency reaches 95%.

Embodiment 3

[0023] The ammonia concentration in the imported gas composition is 20%, and the gas pressure is 8 atm. The ionic liquid used for absorption is metal type ionic liquid 1-butyl-3-methylimidazole cobalt thiocyanate ([Bmim] 2 [Co(NCS)] 4 ). The rotor filler is polypropylene wire mesh filler, and the rotor speed is 2700 rpm. The temperature of the ionic liquid is 30°C, the distribution of liquid mist is 8, the pipe diameter is 30mm, 4 layers of hollow cone nozzles are installed, and 4 nozzles are evenly distributed in the upper single layer. The gas-liquid ratio is 200:1, and the ammonia gas removal efficiency reaches 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com