Stabilizer composition, liquid formula milk and preparation method of liquid formula milk

A technology of composition and formula milk, which is applied in the field of dairy product preparation, can solve the problems that the stability of liquid formula milk needs to be improved, and achieve the effects of enhancing stability, system stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

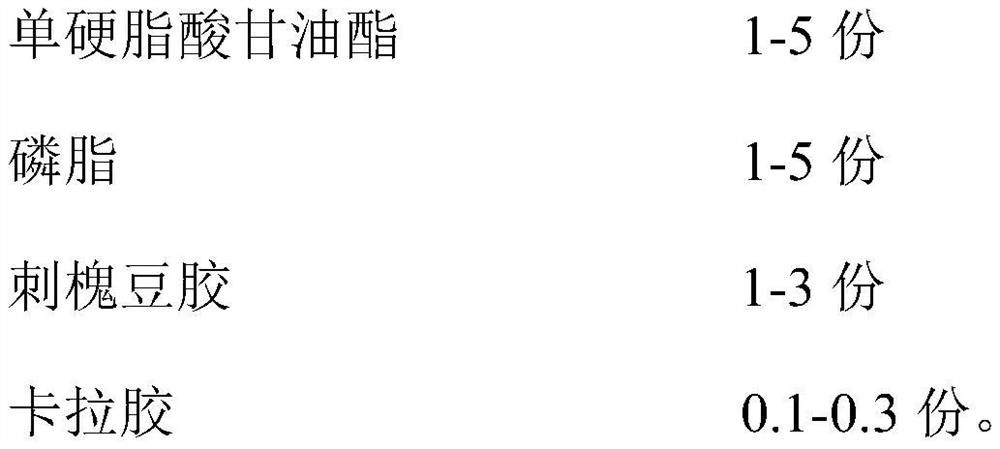

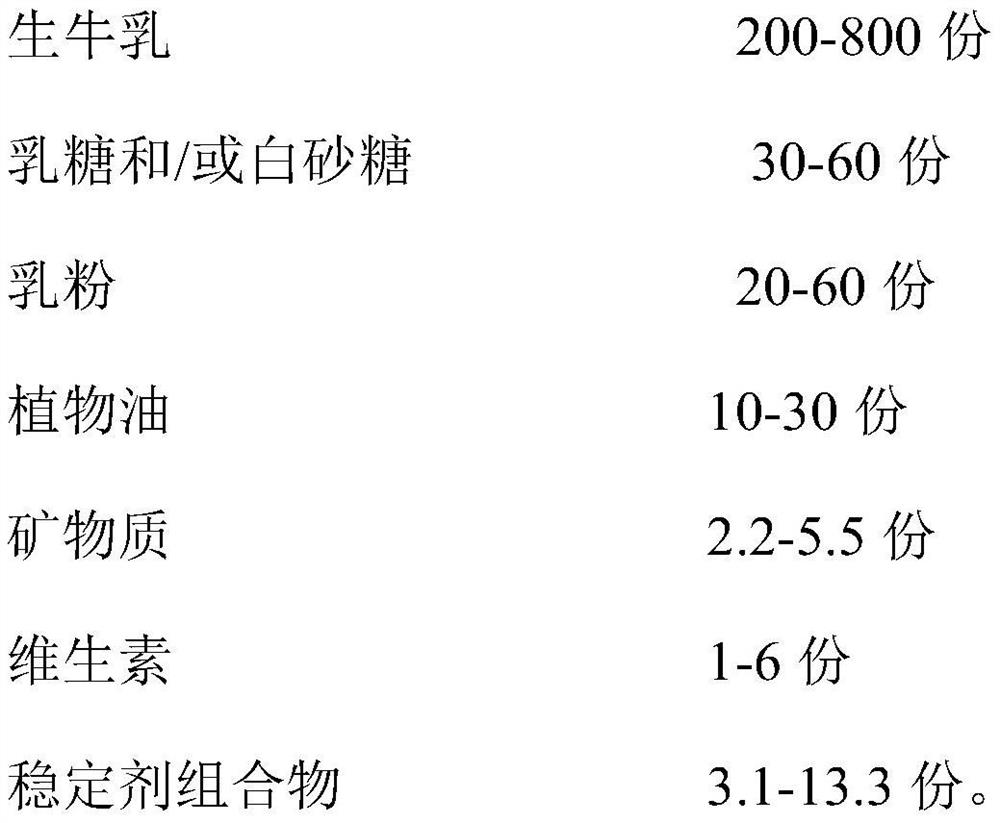

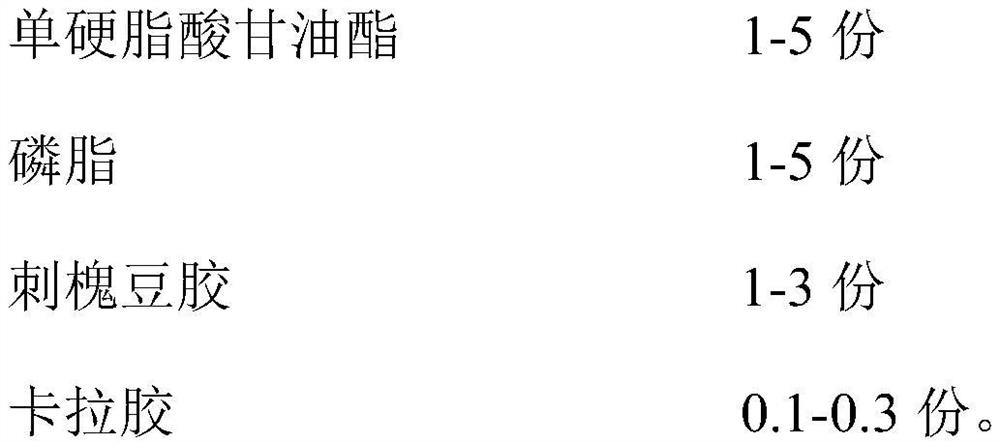

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a liquid formula milk and its preparation method. Based on 1000kg, the liquid formula milk is composed of the following raw materials: 200kg of raw milk, 30kg of lactose, 10kg of whole milk powder, 10kg of skimmed milk powder, 10kg of compound vegetable oil, 2kg of the first mineral, 2kg of the second mineral, and the first vitamin 0.5kg, 0.5kg of the second vitamin and 3.1kg of the stabilizer composition, and the balance is water; wherein, based on the mass of the metal element in the first mineral, the first mineral consists of 0.05kg of calcium salt and 0.01kg of sodium salt and 0.0001kg of copper salt, the calcium salt is calcium carbonate, the sodium salt is sodium citrate, and the copper salt is copper sulfate; based on the mass of metal elements in the second mineral, the second mineral is composed of 0.05kg of magnesium oxide , 0.01kg of potassium salt, 0.01kg of iron salt, and 0.001kg of zinc salt, the potassium salt is potassium chlori...

Embodiment 2

[0054] This embodiment provides a liquid formula milk and its preparation method. Based on 1000kg, the liquid formula milk consists of the following raw materials: 600kg of raw milk, 40kg of lactose, 20kg of whole milk powder, 15kg of skimmed milk powder, 20kg of compound vegetable oil, 1.1kg of the first mineral, 1.1kg of the second mineral, One vitamin 1.5kg, the second vitamin 1.5kg and stabilizer composition 8.2kg, the balance is water; wherein, in terms of the mass of metal elements in the first mineral, the first mineral is composed of 0.06kg of calcium salt, 0.015kg The sodium salt and 0.0003kg of copper salt, the calcium salt is calcium chloride, the sodium salt is sodium chloride, and the copper salt is copper citrate; based on the mass of the metal element in the second mineral, the second mineral is composed of 0.055 kg of magnesium salt, 0.015kg of potassium salt, 0.015kg of iron salt, and 0.0015kg of zinc oxide, the magnesium salt is magnesium hydrogen phosphate, ...

Embodiment 3

[0062] This embodiment provides a liquid formula milk and its preparation method. Based on 1000kg, the liquid formula milk consists of the following raw materials: 800kg of raw milk, 60kg of lactose, 30kg of whole milk powder, 30kg of skimmed milk powder, 30kg of compound vegetable oil, 2.7kg of the first mineral, 2.8kg of the second mineral, One vitamin 3kg, the second vitamin 3kg and stabilizer composition 13.3kg, the balance is water; wherein, based on the mass of metal elements in the first mineral matter, the first mineral matter consists of 0.08kg of calcium salt, 0.03kg of sodium salt and 0.0005kg of copper salt, the calcium salt is tricalcium phosphate, the sodium salt is sodium citrate, and the copper salt is copper citrate; based on the mass of the metal element in the second mineral, the second mineral consists of 0.06kg The potassium salt of magnesium oxide, 0.03kg, the iron salt of 0.02kg, the zinc oxide of 0.005kg are formed, and described potassium salt is potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com