Method for cleaning indium phosphide wafer

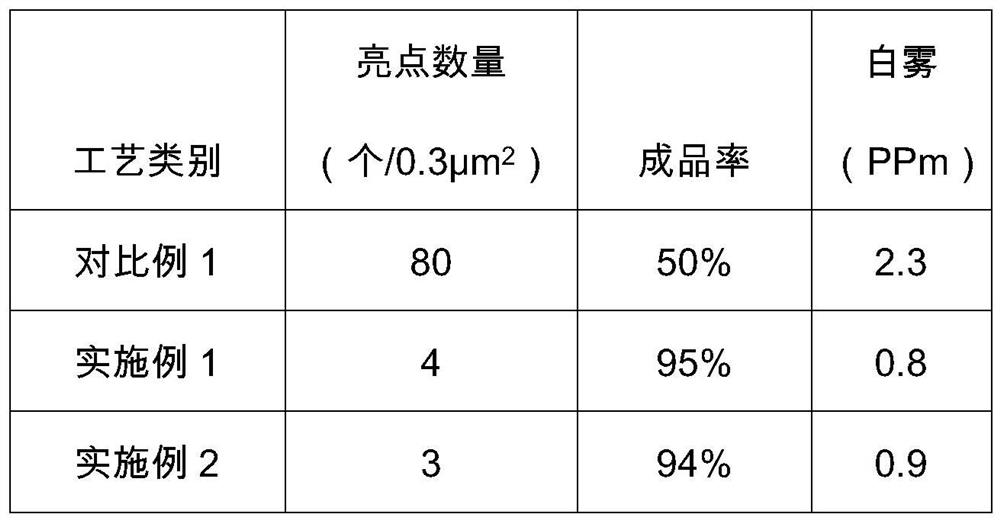

A technology of indium wafers and wafers, which is applied in the cleaning field of indium phosphide wafers, can solve the problems of poor yield and many bright spots on the wafer surface, and achieve the effects of increased yield, reduced bright spots, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

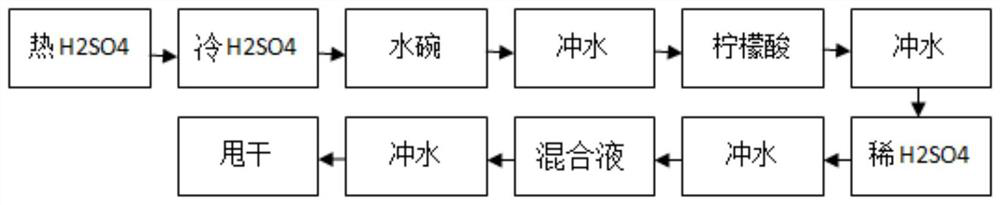

[0034] Take a 4-inch indium phosphide wafer, polish it and dry it, and perform the following steps in sequence: figure 1 As shown, use a cleaning jig to clamp, soak in hot sulfuric acid (mass concentration: 50%) at 30°C for 20S, soak in cold sulfuric acid (mass concentration: 50%) at 20°C for 15S; immerse in a water bowl filled with clean water Soak in water for 3s; then take it out and immediately put it into the 1# overflow tank, and at the same time use a water gun to rinse the overflow tank to keep the water overflowing. The cleaning time: 15S, and the overflow water volume is 20L / min; The mass ratio of acid to water is 1:500) Soak in 15S; put into 2# overflow tank, and at the same time use a water gun to rinse the overflow tank to keep the water overflowing, cleaning time: 5S, overflow water volume is 30L / min ;Soak in dilute sulfuric acid (mass concentration: 3%) at normal temperature for 15S, put into 3# overflow tank, and use a water gun to rinse the overflow tank to ke...

Embodiment 2

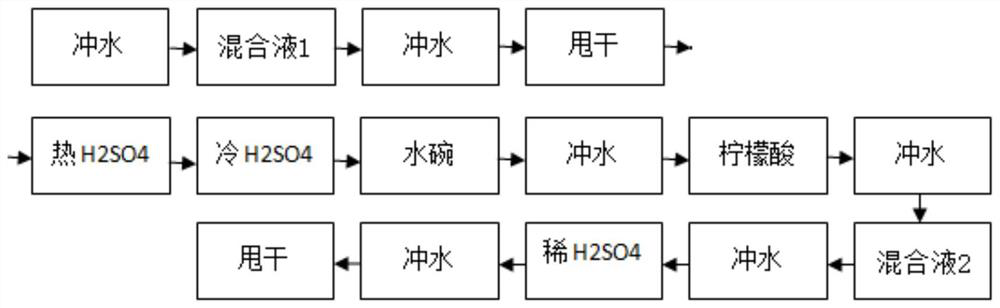

[0036] Take a 4-inch indium phosphide wafer, polish it and dry it, and proceed as follows in sequence: use a cleaning jig to clamp it, soak it in 35°C hot sulfuric acid (50% mass concentration) for 15 seconds, and soak it in 15°C cold sulfuric acid (mass concentration is 50%). Concentration is 50%) in the water for 20S; immersed in a bowl filled with clean water for 2s; then take it out and immediately put it into the 1# overflow tank, and at the same time use a water gun to rinse the overflow tank to keep the water overflowing, cleaning time: 10S, The overflow water volume is 25L / min; soak in citric acid water at room temperature (the mass ratio of citric acid to water is 1:1000) for 20S; put it into the 2# overflow tank, and use a water gun to flush the overflow tank at the same time to keep the water Overflow state, cleaning time: 15S, the overflow water volume is 10L / min; soak in dilute sulfuric acid (mass concentration: 2%) at room temperature for 20S, put it into the 3# o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com