Polyimide composite film as well as preparation method and application thereof

A technology of polyimide and polyimide matrix, which is applied in the direction of insulators, electrical components, insulators, etc., and can solve problems such as unsatisfactory cables and cracking of composite films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides the preparation method of polyimide composite membrane described in above-mentioned scheme, comprises the following steps:

[0038] Mixing dianhydride monomers, diamine monomers and aprotic polar solvents for the first polycondensation reaction to obtain polyamic acid;

[0039] Forming the polyamic acid into a film and performing a first imidization reaction to form a first film layer; the degree of progress of the first imidization reaction is 40% to 80%;

[0040] Mix dianhydride monomers, fluorine-containing diamine monomers and aprotic polar solvents, or mix fluorine-containing dianhydride monomers, diamine monomers and aprotic polar solvents, and perform a second polycondensation reaction to obtain Fluoropolyamic acid;

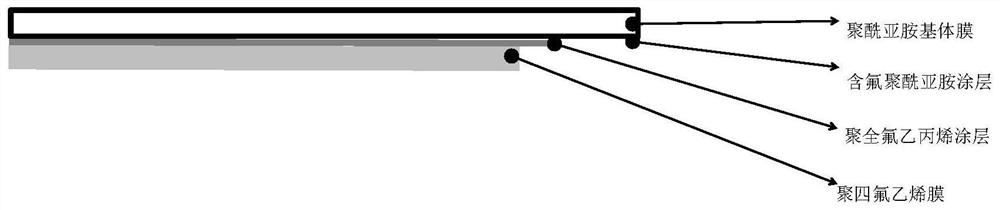

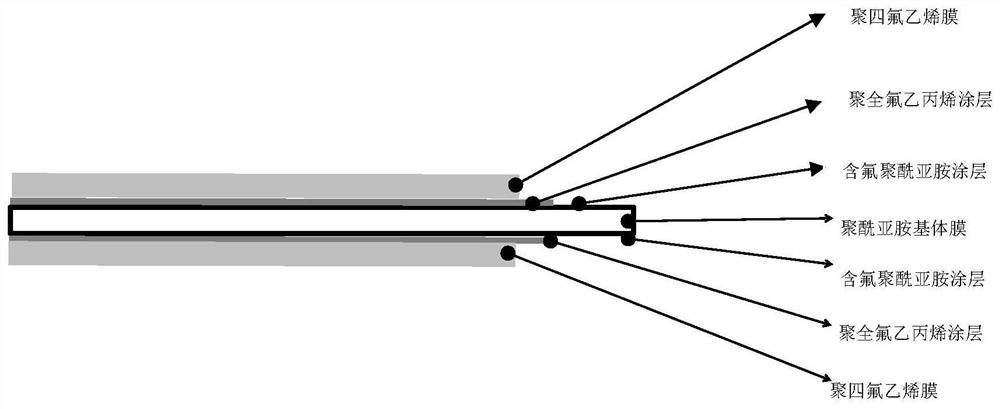

[0041] Coating the fluoropolyamic acid onto the surface of the first film layer, and performing a second imidization reaction to obtain a polyimide matrix film and a fluorine-containing polyimide coating;

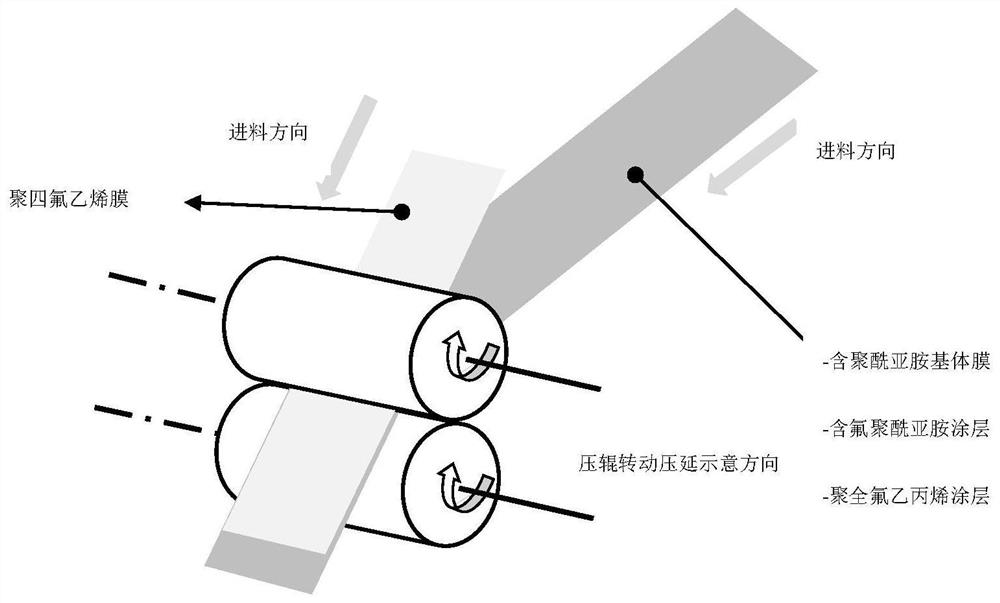

[0042] Co...

Embodiment 1

[0069] Pyromellitic anhydride monomer (PMDA: 5 grams) and 4,4'-diaminodiphenyl ether (ODA: 4.59 grams) monomer in N, N-dimethylacetamide (DMAc ultra-dry 99.8%: 38.376 grams) under normal temperature in the solution, carry out polycondensation reaction for the first time, react and make polyamic acid in 12 hours;

[0070] The polyamic acid is formed into a film and the first imidization reaction is carried out under vacuum conditions at 250° C., and the reaction is carried out for 30 minutes (the degree of progress of the imidization reaction is 40%) to obtain the first film layer;

[0071] Pyromellitic anhydride monomer (PMDA: 2.05 g) and 2,2'-bis(trifluoromethyl) diaminobiphenyl (TMAc: 2.946 g) in N,N-dimethylacetamide (DMAc super Dry 99.8%: 9.49 g) in the solution at room temperature to carry out the second polycondensation reaction, and react for 12 hours to obtain fluorine-containing polyamic acid;

[0072] The fluorine-containing polyamic acid is sprayed on the surface o...

Embodiment 2

[0076] The difference from Example 1 is that the thickness of the polyimide base film is 35 μm, the thickness of the fluorine-containing polyimide coating is 0.1 μm, the thickness of the polyperfluoroethylene propylene coating is 1.5 μm, and the polytetrafluoroethylene coating is 1.5 μm. The thickness of the vinyl film was 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com